Pressure bandage based on film pressure sensor

A film pressure and sensor technology, which is applied in the field of medical supplies, can solve the problems of the inability to quantify the tightness of the bandage, the inability to lift the bandage, and the low pressure of the bandage, so as to achieve the effect of key monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

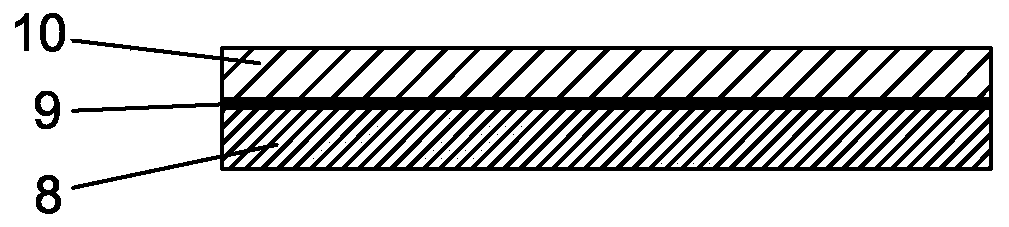

[0018] A pressure bandage based on a film pressure sensor, comprising a bandage layer 8 , an adhesive layer 9 and a sensor layer 10 . Bandage layer 8 usually uses non-woven fabric 5, and non-woven fabric 5 is a medical standard, and the length of bandage layer 8 can be set according to the specific use site and situation of the bandage. One side of the bandage layer 8 is coated with a layer of adhesive, and the back side of the sensor layer 10 is attached to the bandage layer 8 through the adhesive.

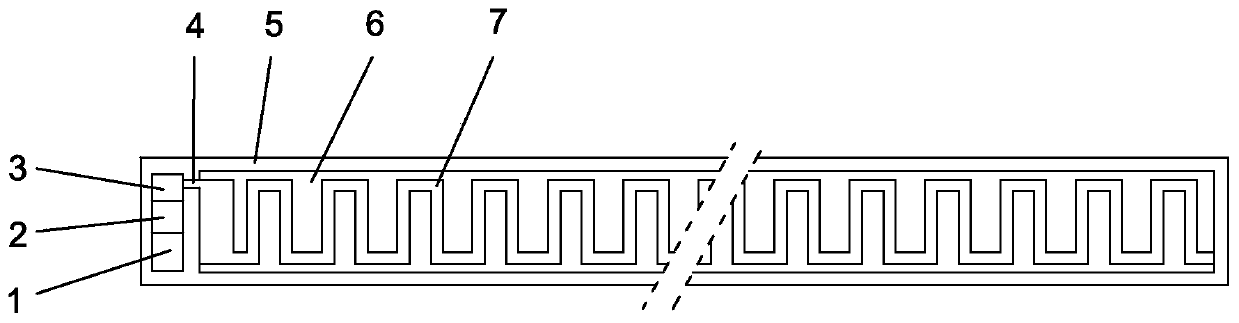

[0019] The sensor layer 10 includes a thin-film pressure sensor 6, a resistance-voltage conversion module 3, a voltage-pressure fitting module 2 and a wireless module 1. The thin-film pressure sensor 6 is a flexible film, and RP-L-X (Lisense Technology) resistive flexible film can be used The pressure sensor, the flexible film can be better attached to the bandage layer, and can be used in different parts of the bandage. There is a serpentine conductive pattern 7 on the surface ...

Embodiment 2

[0021] A pressure bandage based on a film pressure sensor, comprising a bandage layer 8 , an adhesive layer 9 and a sensor layer 10 . Bandage layer 8 usually uses non-woven fabric 5, and non-woven fabric 5 is a medical standard, and the length of bandage layer 8 can be set according to the specific use site and situation of the bandage. One side of the bandage layer 8 is coated with a layer of adhesive, and the back side of the sensor layer 10 is attached to the bandage layer 8 through the adhesive.

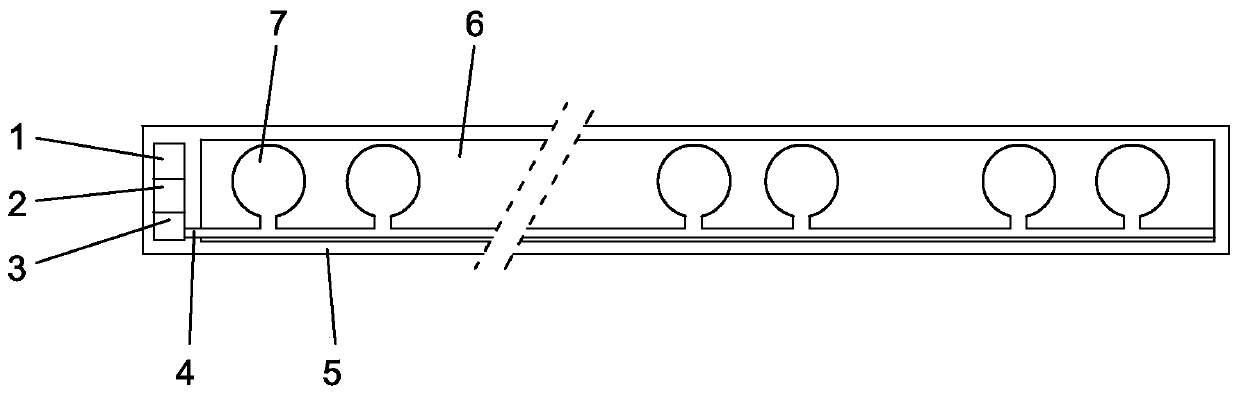

[0022] The sensor layer 10 includes a thin-film pressure sensor 6, a resistance-voltage conversion module 3, a voltage-pressure fitting module 2 and a wireless module 1. The thin-film pressure sensor 6 is a flexible film, and RP-L-X (Lisense Technology) resistive flexible film can be used Pressure sensor, flexible film can fit better with bandage layer. There are a plurality of dispersed circular conductor patterns 7 on the surface of the thin film pressure sensor 6, and the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com