Environment-friendly treatment equipment for intermittent feeding type glass solid wastes

A technology for solid waste and environmental protection treatment, applied in the direction of grain processing, etc., can solve the problems of blockage, waste of resources, inconvenient use of solid waste, etc., and achieve the effect of reducing device cost, reasonable structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

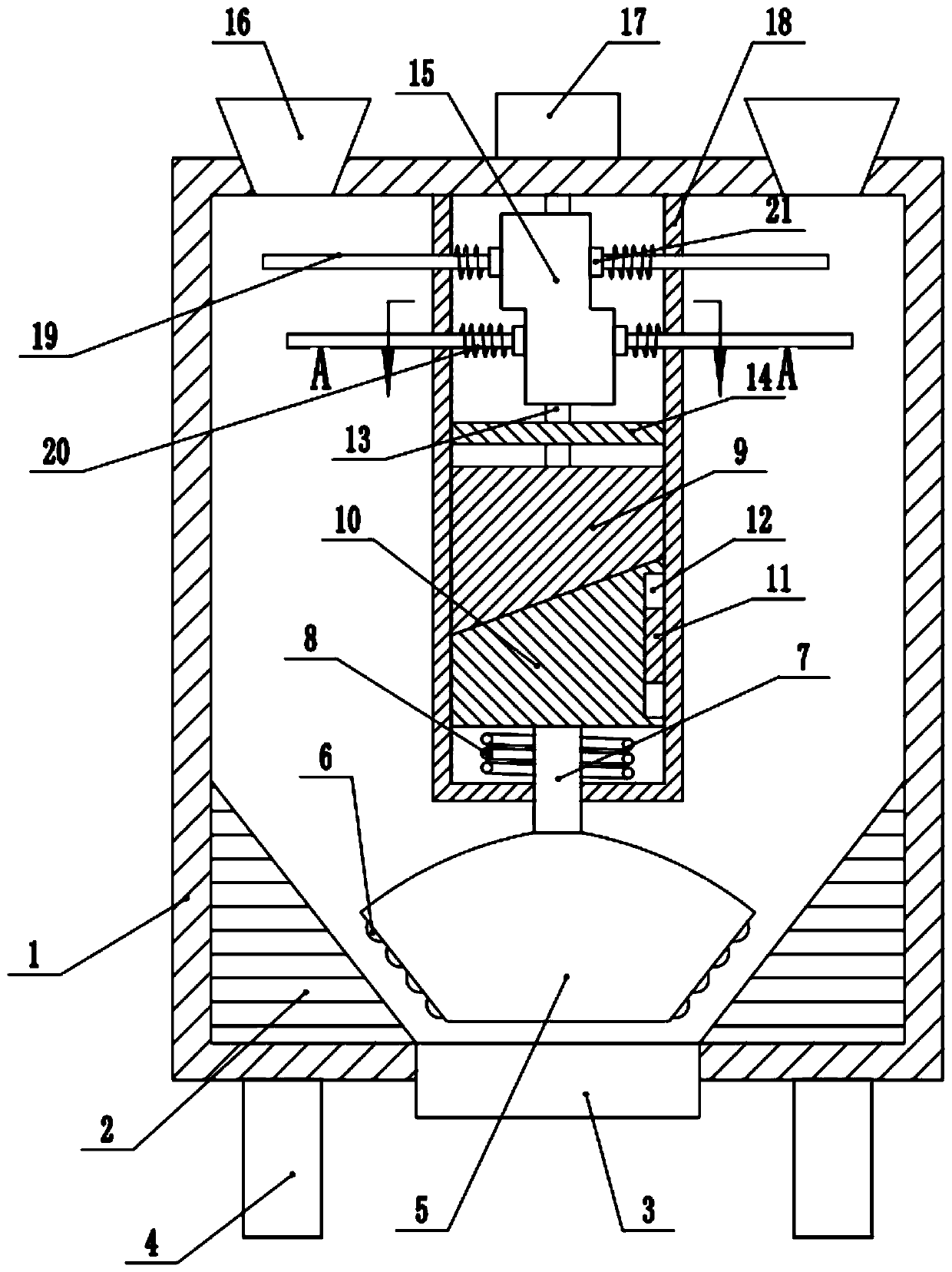

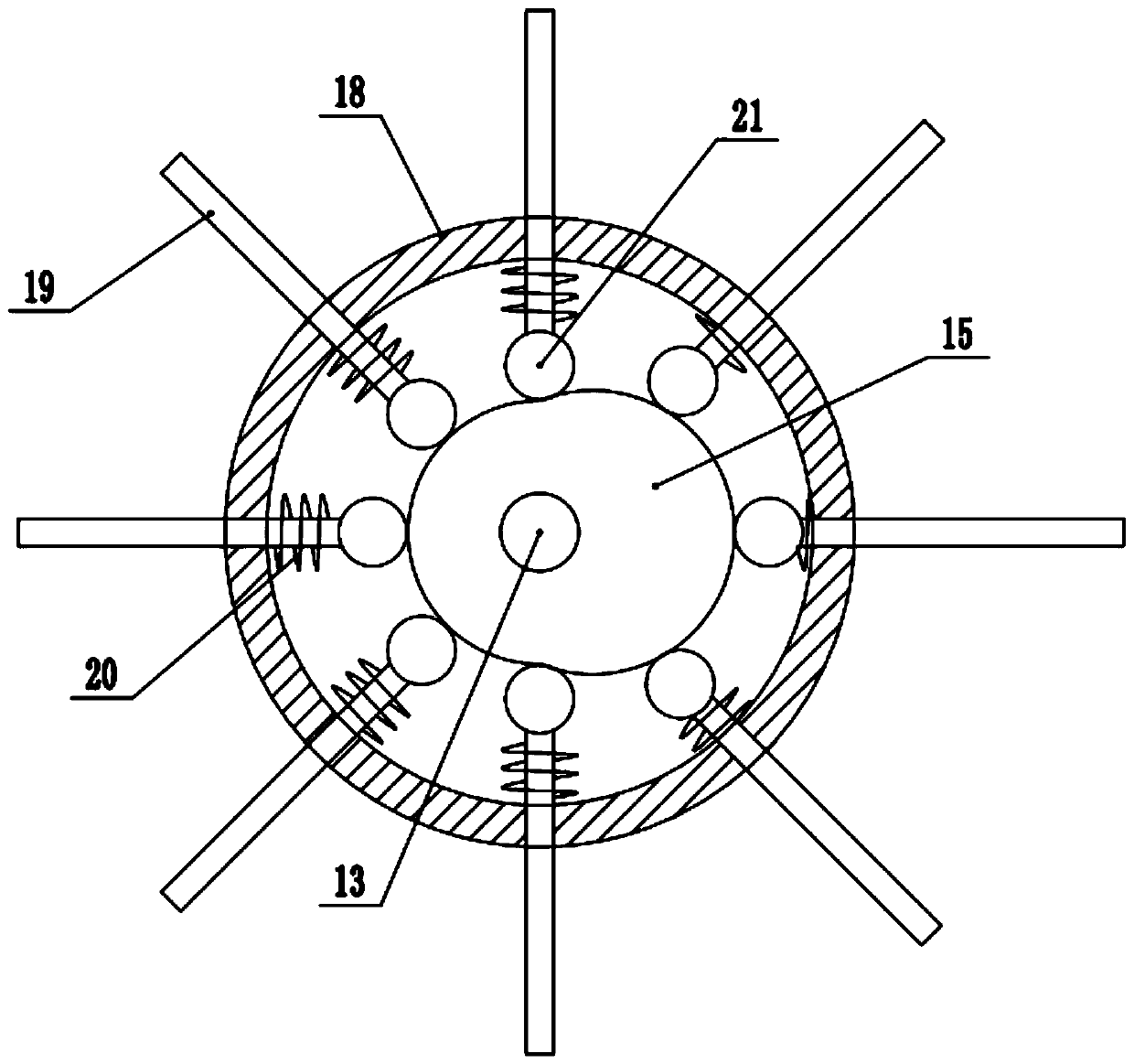

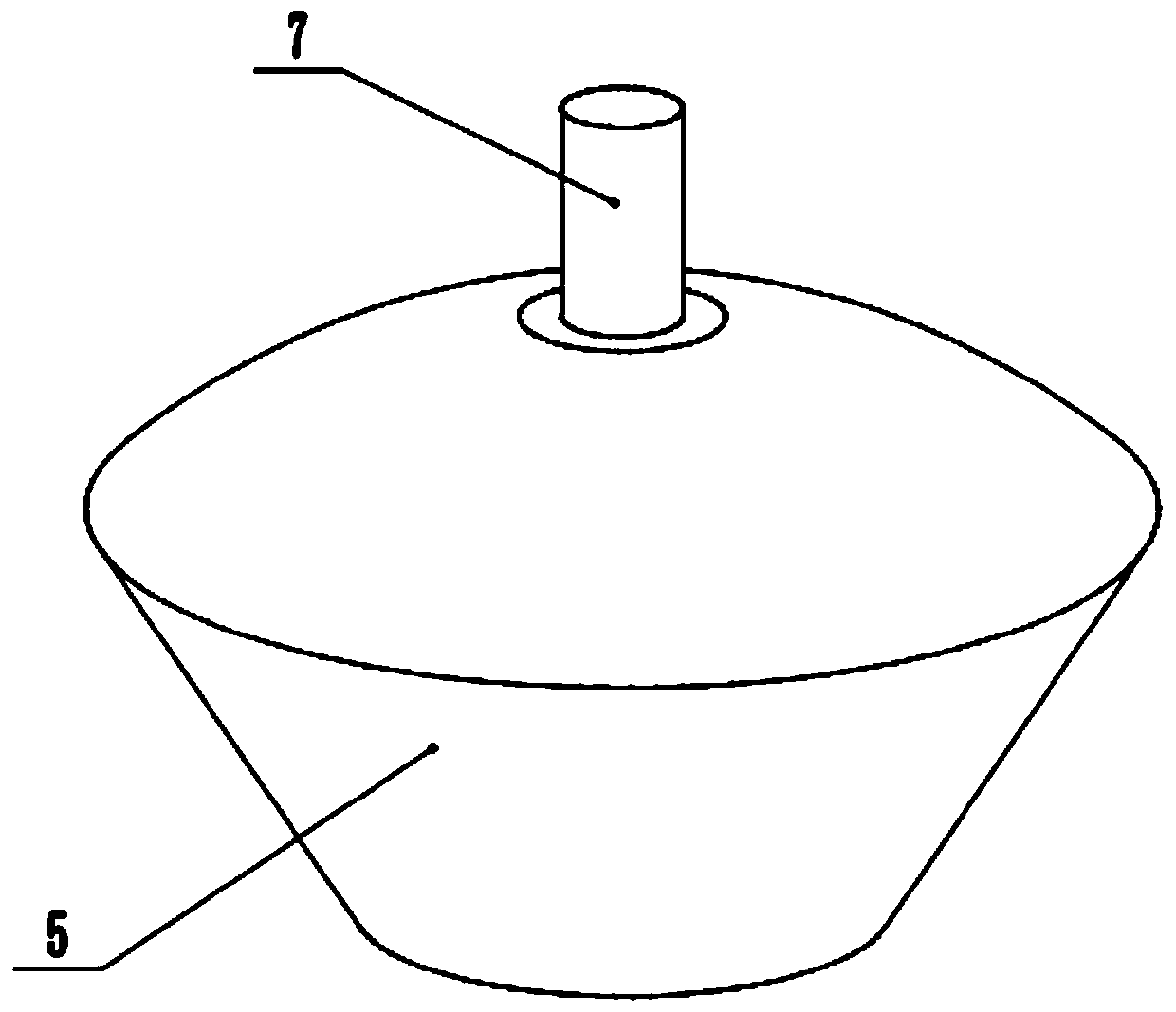

[0028] refer to Figure 1~4 , in an embodiment of the present invention, an intermittent feeding type glass solid waste environmental protection treatment equipment includes a treatment box 1, and a feeding hopper 16 is provided on the outer side of the upper end of the treatment box 1, which is used to realize the internal glass of the treatment box 1. For importing, support legs 4 are installed on both sides of the lower end of the processing box 1 to ensure the support of the entire device. A discharge hopper 3 is installed in the middle of the lower end of the processing box 1 to ensure the export of glass after two crushing treatments. The processing box 1, a fixed cylinder 18 is installed on the top of the interior, and a drive shaft 13 is installed inside the fixed cylinder 18. The top of the drive shaft 13 passes through the processing box 1 and is connected to a drive motor 17, thereby driving the drive shaft 13 to rotate. The middle part of the upper end of the drive ...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a slanted ring 2 is installed at the inner bottom of the processing box 1, and the angle of the inner side of the slanted ring 2 is the same as that of the outer side of the mashing hammer 5. The angles are the same, on the one hand, by setting the inclined block 2 to cooperate with the mashing hammer 5 to increase the crushing capacity, on the other hand, it also ensures that the glass waste is better discharged through the discharge hopper 3 .

[0031] In the present invention, when in use, the glass solid waste is introduced into the treatment box 1 through the hopper 16, and then the drive motor 17 is started, and the drive motor 17 drives the drive shaft to make the double cam column 15 rotate, thereby making the double cam column 15 protrude The part continuously cooperates with the guide block 21, and then under the cooperation of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com