Solid cutter roller and crusher with solid cutter roller

A technology of crusher and knife roller, which is applied in the direction of mechanical material recovery, recycling technology, grain processing, etc., can solve the problems of large main shaft load, small inertia, easy winding, etc., achieve stable crushing, increase inertia, and reduce main shaft load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

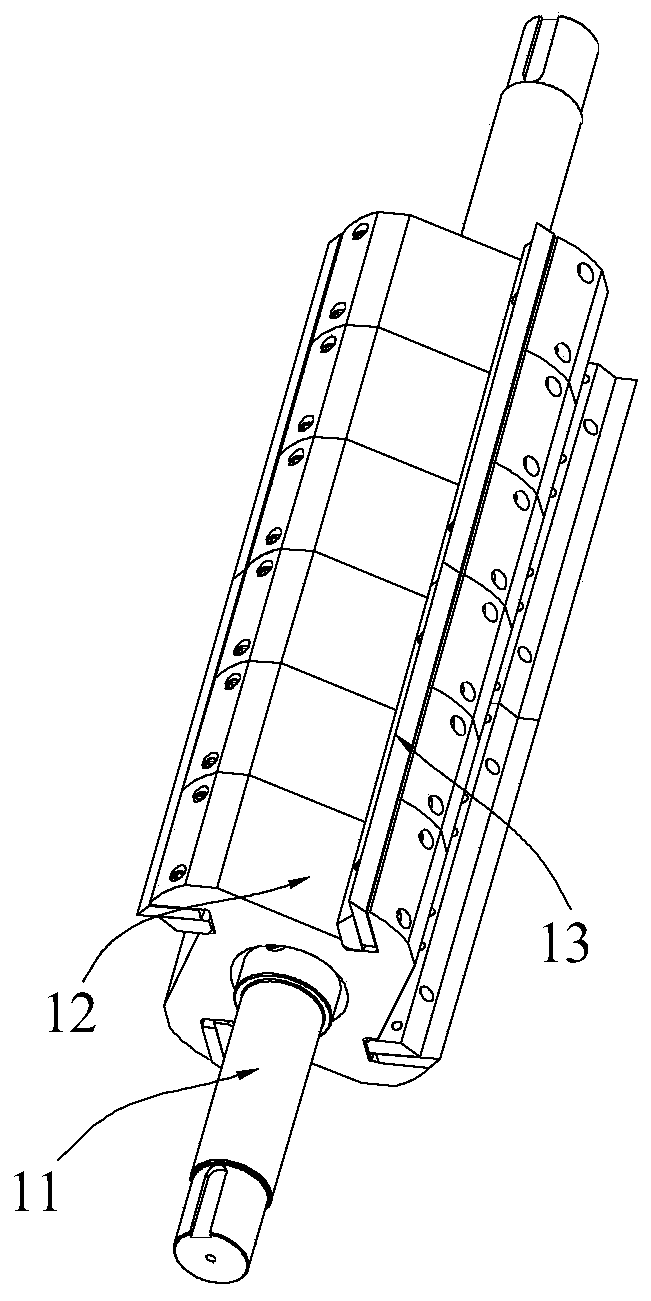

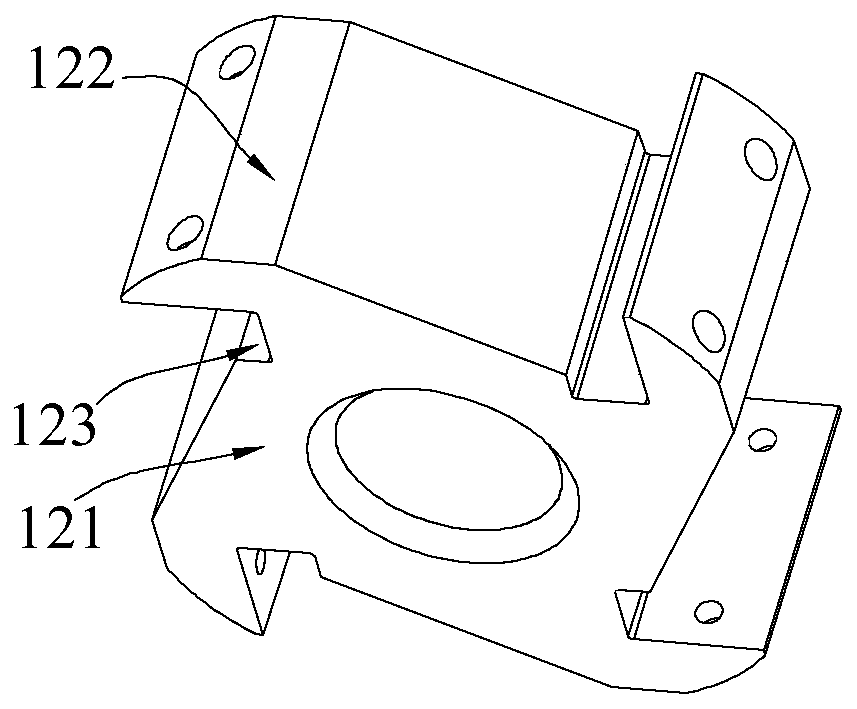

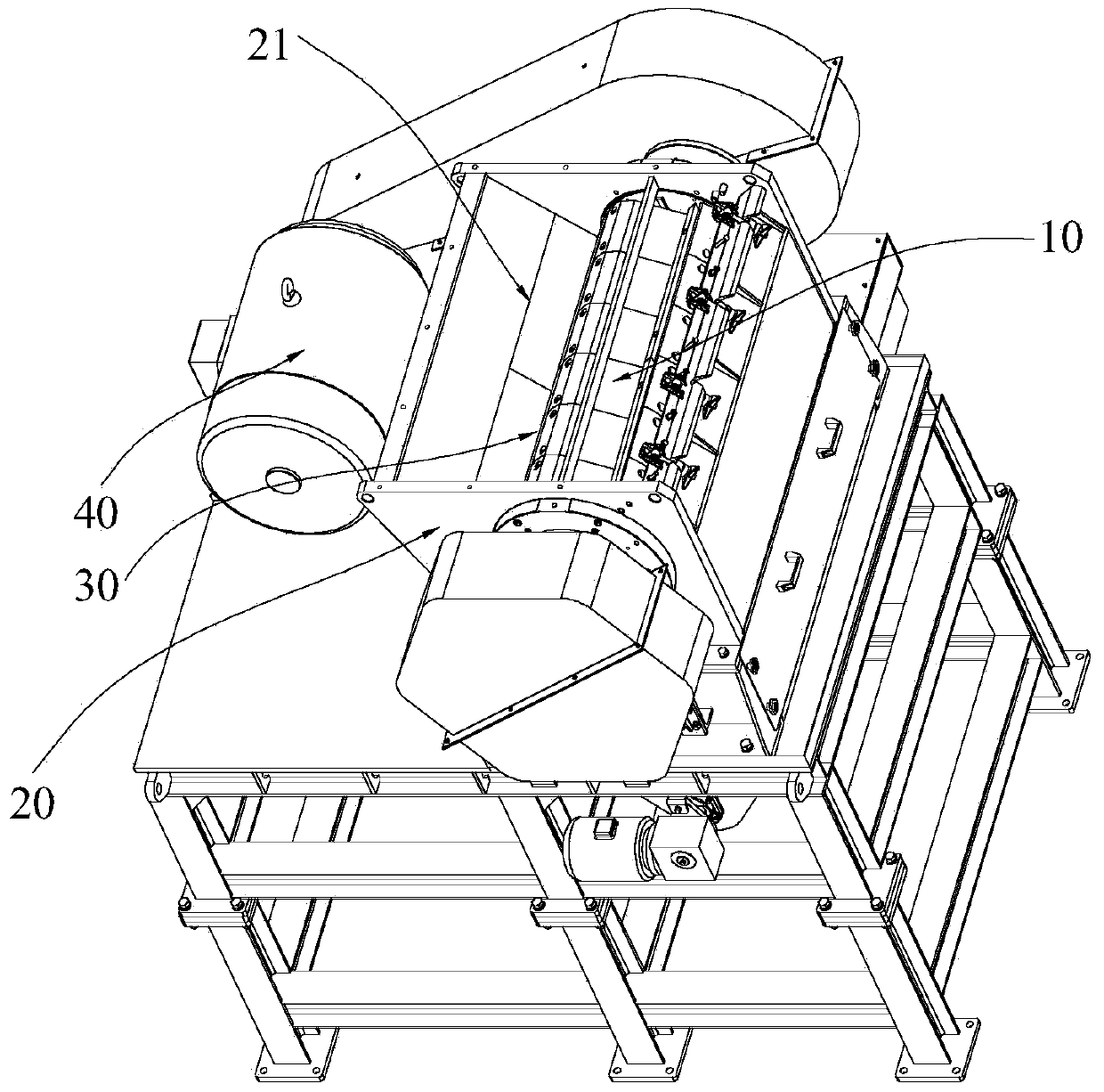

[0023] Such as figure 1 as well as figure 2 A solid knife roll 10 shown includes a knife shaft 11, a plurality of knife seats 12 and blades, and the plurality of knife seats 12 are all set on the knife shaft 11 and fixedly connected to the knife shaft 11, and the plurality of knife seats 12 are along the The axial directions of the cutter shafts 11 are distributed sequentially, so that the end faces of two adjacent cutter seats 12 are attached to each other. In addition, the knife seat 12 includes a base body 121 and a plurality of mounting bodies 122. Specifically, during installation, the base body 121 is set on the knife shaft 11 and fixed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com