Pump pipe washing structure and method

A pump tube and pipeline technology, applied in the pump tube cleaning structure and cleaning field, can solve the problems of complex cleaning structure, easy clogging of pump tubes, cumbersome operation, etc., and achieve the effect of improving cleaning quality, improving cleaning efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

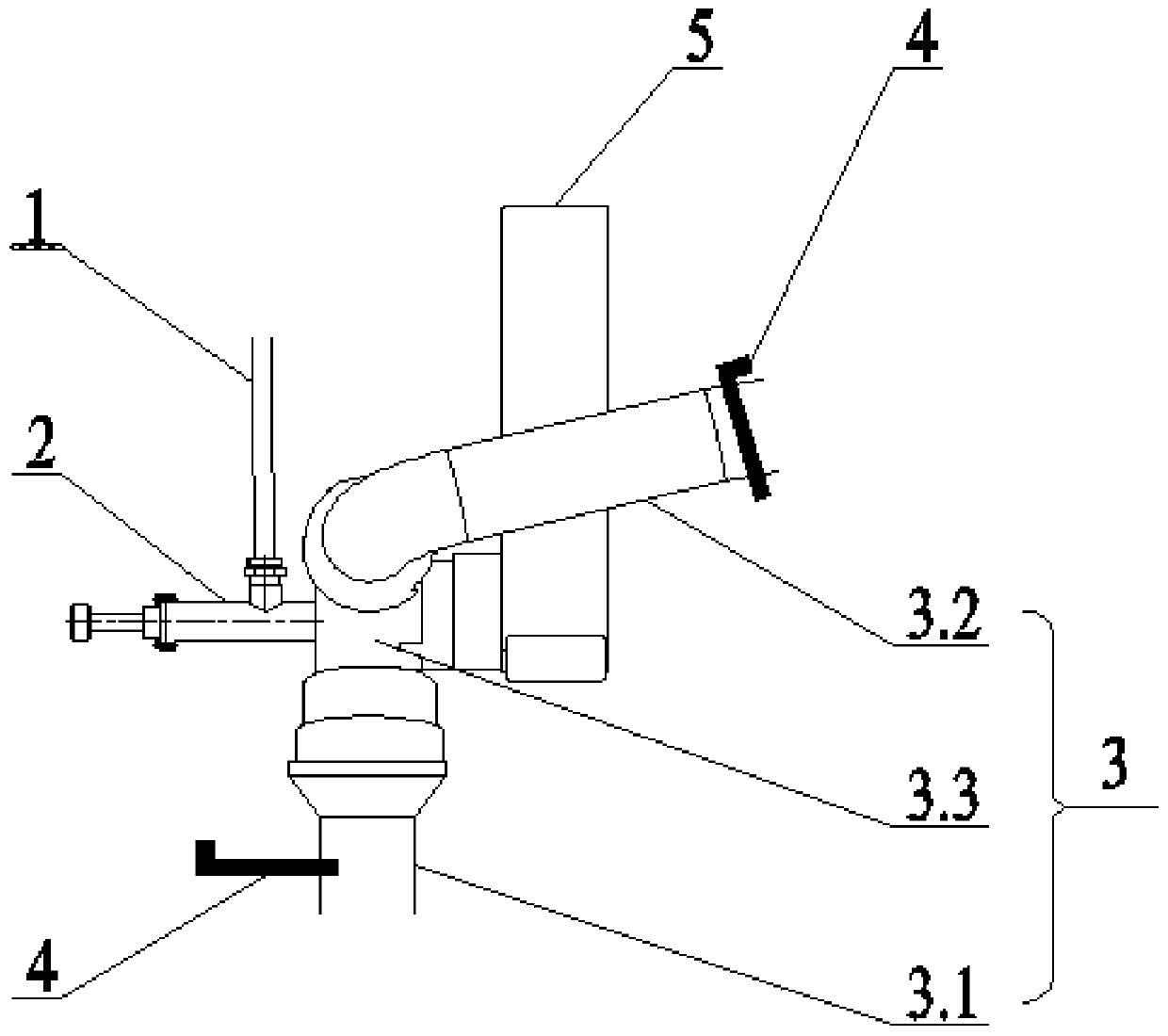

[0030] see Figure 1 ~ Figure 4 , a pump tube cleaning structure and cleaning method, the present embodiment is applied to the pump tube cleaning of the distribution machine on the trolley.

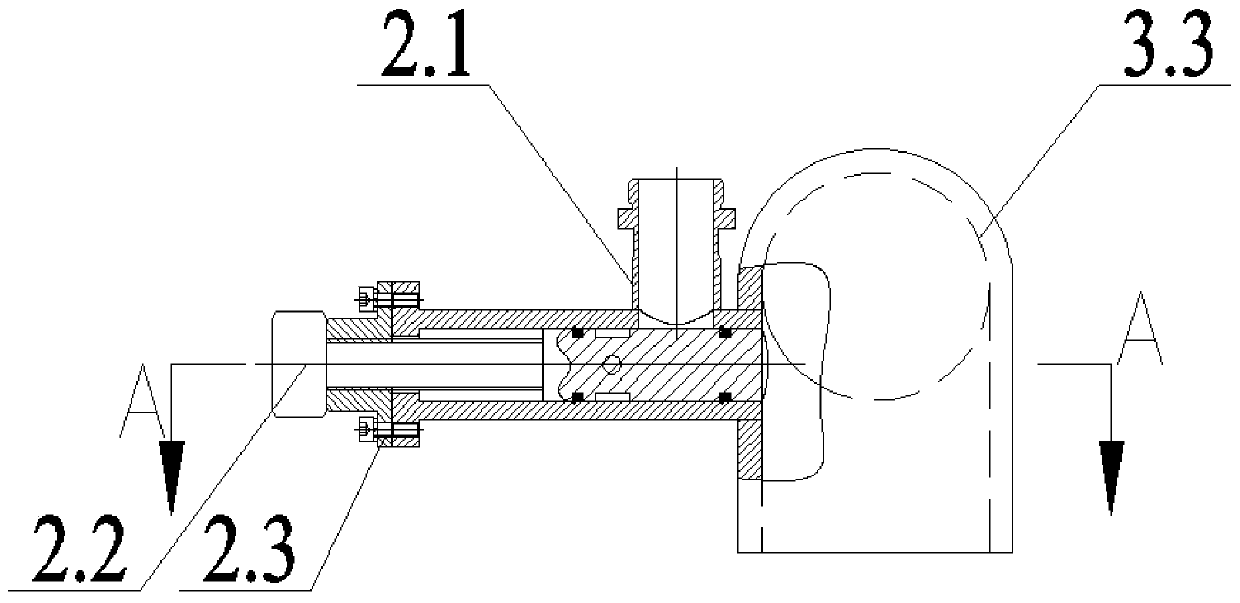

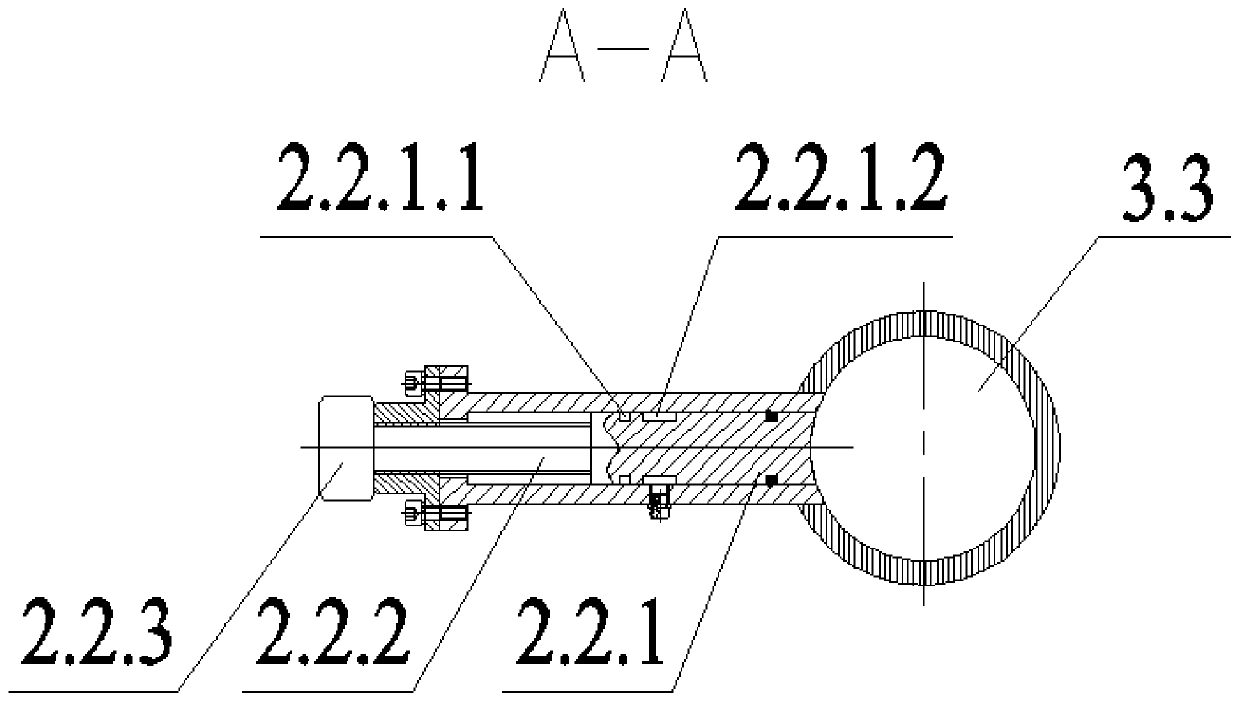

[0031] A pump pipe cleaning structure includes a wind water pipe 1, a valve 2 and a pump pipe 3; the valve 2 includes a valve body 2.1 and a valve core 2.2, and the two interfaces of the valve body 2.1 are respectively connected to the first end of the wind water pipe 1 and the pump pipe 3 The connection holes on the outer wall are connected, and the valve core 2.2 matches the cavity in the valve body 2.1 to control the connection and disconnection of the two interfaces of the valve body 2.1. Such as figure 2 As shown, the direction of the arrow in the figure indicates the screwing direction of the valve core 2.2, and the valve 2 is in the closed state; image 3 As shown, the direction of the arrow in the illustration indicates the direction in which the valve core 2.2 is unscrewed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com