Emission reduction device of cold header

A cold heading machine and power device technology, applied in the direction of heading presses, forging/pressing/hammer devices, swaging presses, etc., can solve problems affecting the working environment of workers, polluting air, cold heading machines and workpiece corrosion, etc. , to achieve the effect of improving the working environment, reducing oil fume and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

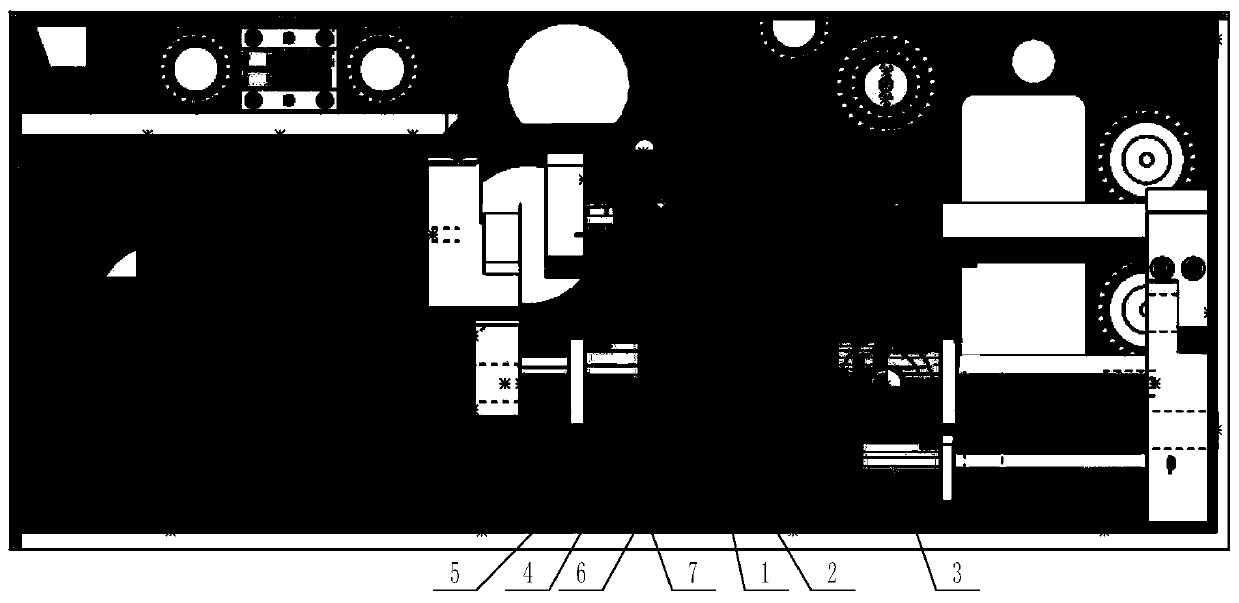

[0012] As shown in the figure, a cold heading machine emission reduction device of the present invention includes a plurality of pistons 1, the pistons include a piston cylinder 2 and a piston rod 3, the piston rod is installed in the piston cylinder, the piston rod is provided with an air inlet 4, and The air port is provided with an intake check valve 5, and the flow direction of the intake check valve is to flow from the outside to the inside of the piston cylinder. The piston cylinder is also provided with an exhaust port 6, and the exhaust port is provided with an exhaust check valve 7. The flow direction of the gas check valve is from the inside of the piston cylinder to the outside.

[0013] In this embodiment, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap