Body frame and low-wind-resistance passenger car

A frame and body technology, applied in the field of body frame and low wind resistance passenger cars, can solve the problems of vehicle space waste, low interior space, poor passability, etc., and achieve the effect of reducing adsorption force and wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

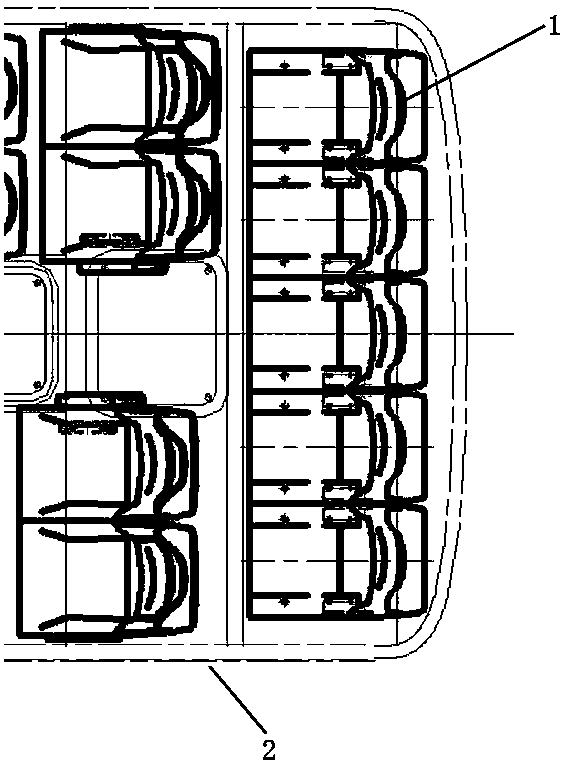

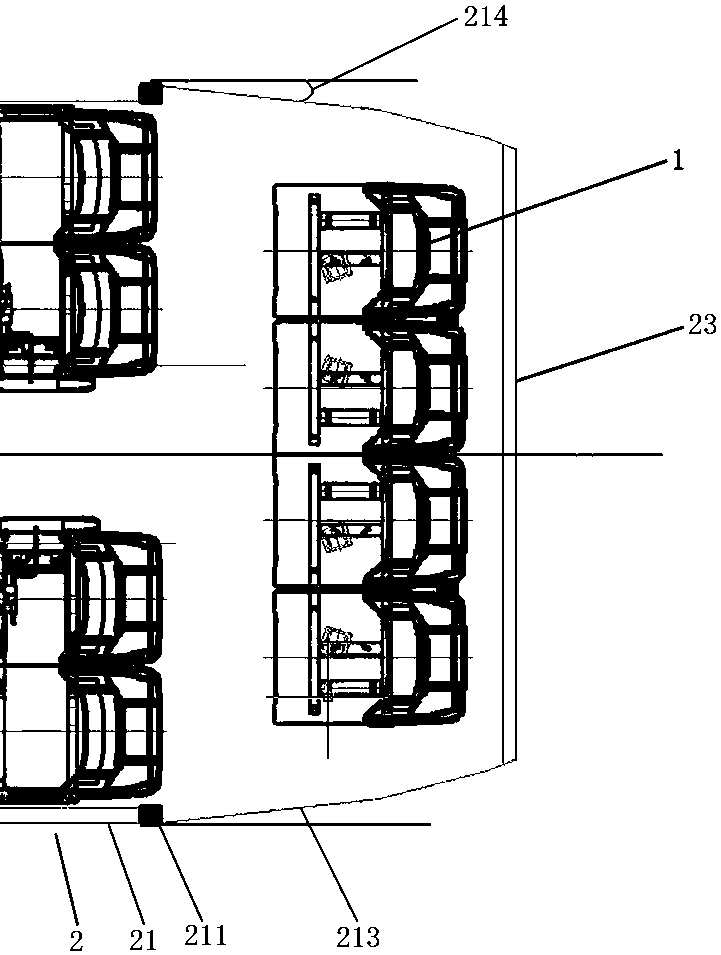

Image

Examples

Embodiment 9

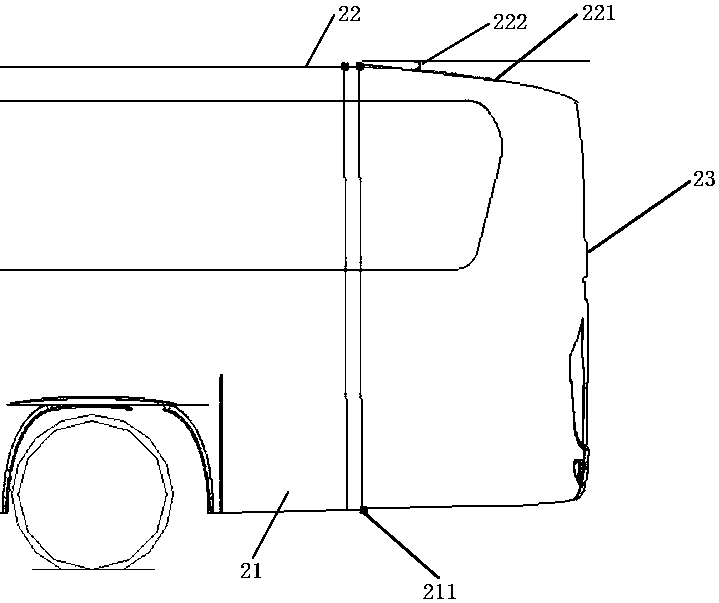

[0038] Embodiment 9: In the range of the pressing angle of 5°-23°, preferably, the pressing angle is set to 13°.

[0039] Considering the height of a general passenger car, when the upper frame of the body frame of the car body is pressed down from the last two columns, the downward pressure distance of the upper frame in the vertical direction is too large or too small, which is not conducive to reducing the negative pressure area Therefore, in Embodiment 10, the vertical pressing distance of the top frame is controlled at no more than 170mm, so that the effect of further reducing the wind resistance cannot be effectively played because the pressing distance is too small. Also, the interior space of the car will not be excessively squeezed due to an excessively large pressing distance, resulting in the rear of the car body being too low, causing inconvenience to the rear passengers in the car.

[0040] The various embodiments above are some improvements to the body frame of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com