Full-automatic safety traffic cone stacking and recovering device and method

A safety cone and fully automatic technology, which is applied to the stacking of objects, the unstacking of objects, and the objects on conveyors, etc., can solve the problems of finding the location, such as risks, increased safety hazards, and strong vehicle specificity, so as to avoid trouble The effect of safety hazard, strong reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

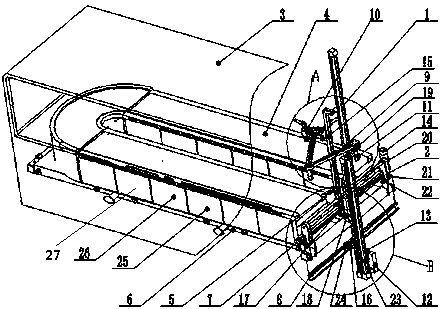

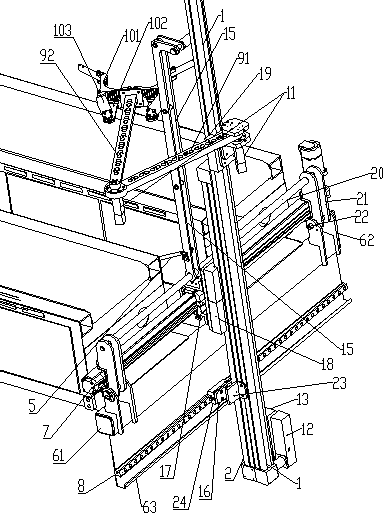

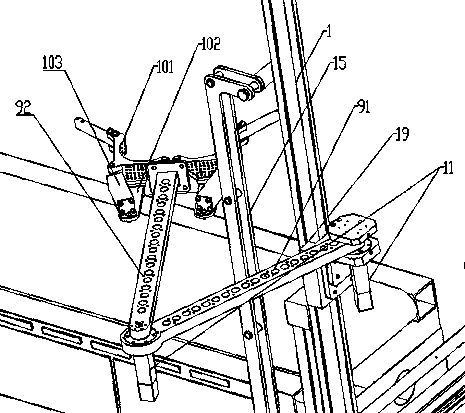

[0049] Such as Figure 1-4 As shown: this embodiment is a fully automatic stacking and recycling safety cone equipment, including a base 6 and a U-shaped conveying unit 4 arranged on the top of the base 6, and one end of the base 6 near the opening end of the U-shaped conveying unit 4 is provided with Connecting rod 61, the length of connecting rod 61 is greater than the opening end width of U-shaped conveying unit 4, is respectively provided with connector 62 at the top of connecting rod 61 being positioned at U-shaped conveying unit 4 both sides, is respectively rotatably connected with The double ear plate 21, the side of the double ear plate 21 facing the opening end of the U-shaped conveying unit 4 is formed with a bayonet, and the lateral moving linear guide rail 7 is arranged in the bayonet, and the lateral moving linear guide rail 7 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com