Mine comprehensive mechanized coal mining equipment assembling-disassembling lifting device

A technology for hoisting devices and fully mechanized mining equipment, applied in hoisting devices, portable hoisting devices, earthwork drilling and mining, etc., can solve problems such as waste, difficult handling of wire ropes, and large columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

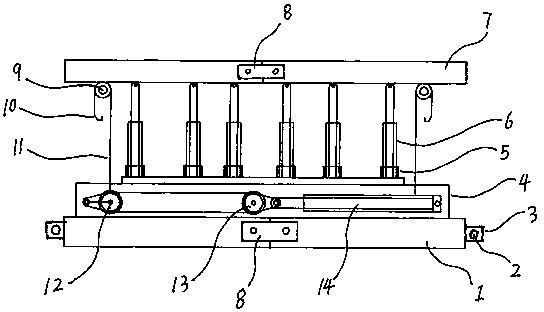

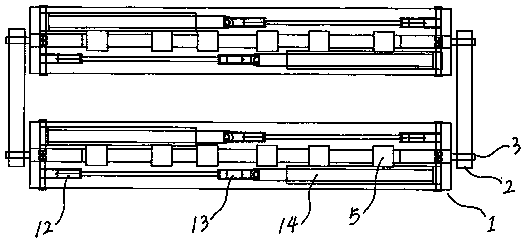

[0013] Depend on figure 1 , figure 2 It can be seen that the present invention includes two bases 1 arranged parallel and side by side. The base is made of a square shape by welding steel plates for mining. The base adopts a two-stage structure for easy transportation, and is connected and fixed by 8 rigid fixed plates to form a whole. A bottom frame 4 is fixedly arranged on each base, and the bottom frame adopts a mining steel plate welding process to be made into a groove shape. Along the direction of the bottom frame, six column sockets 5 are fixedly arranged in the middle of the interior, and a hydraulic column 6 is erected and fixed in each column socket. Size and shape should match each other. A top plate 7 is fixedly connected to the top of the piston of the hydraulic column. The top plate is made of mining U-shaped steel. The top plate adopts a two-stage structure for easy transportation. The rigid fixed connection 8 plates are connected and fixed to form a whole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com