An energy-saving thermal deaerator

A thermal deoxygenation, energy-saving technology, applied in the direction of degassed water/sewage treatment, etc., can solve the problems of low heating efficiency, steam energy waste, energy waste, etc., achieve uniform heating, improve overflow efficiency, and high heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

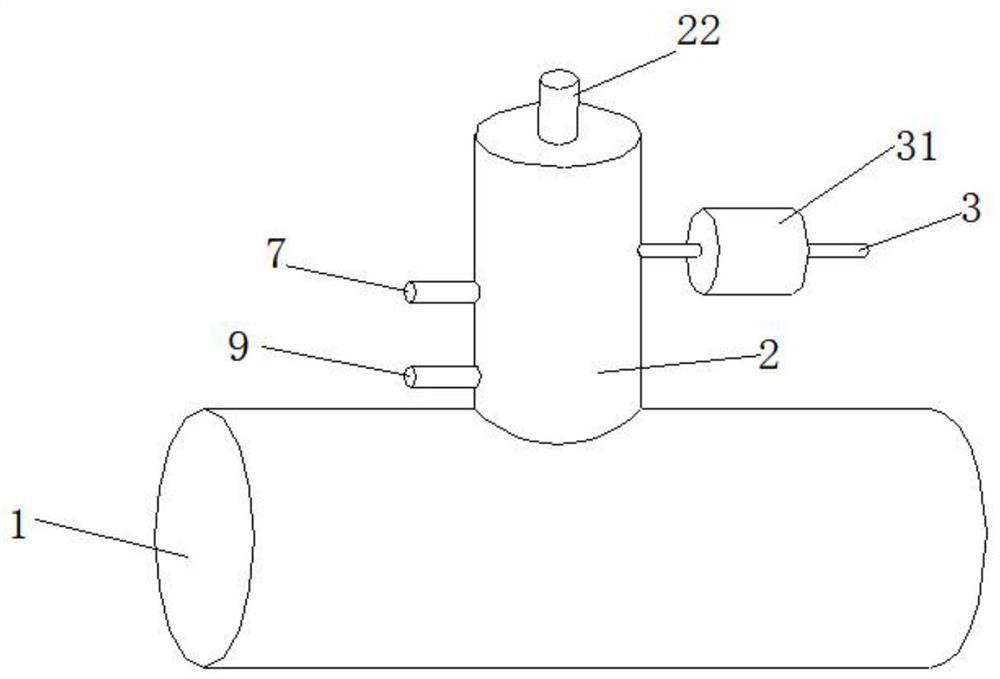

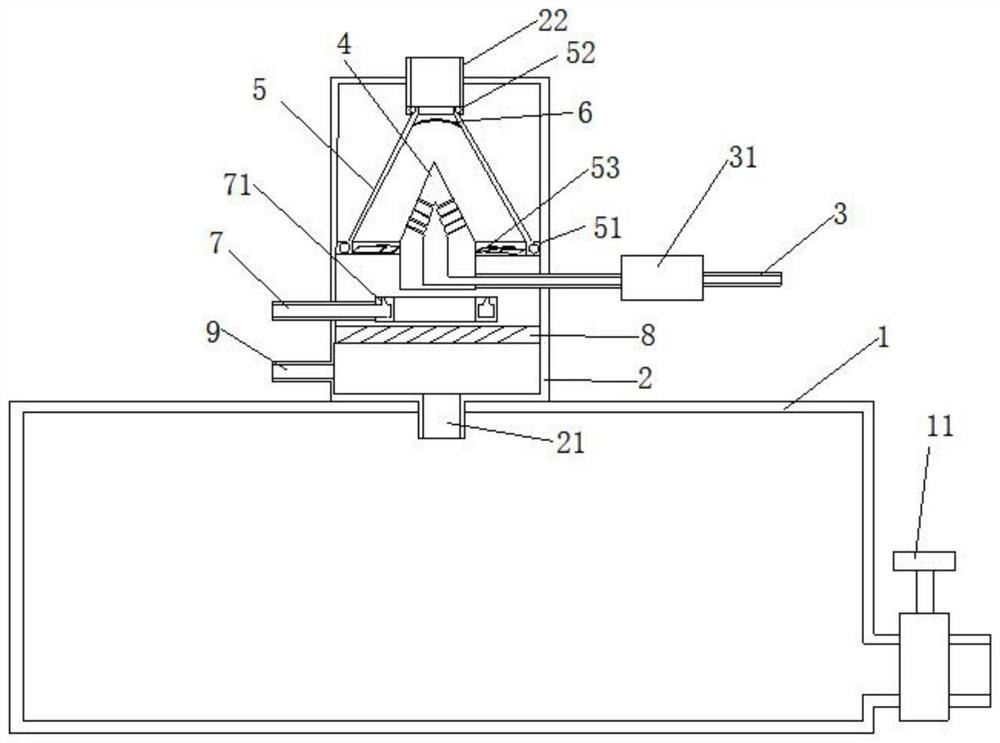

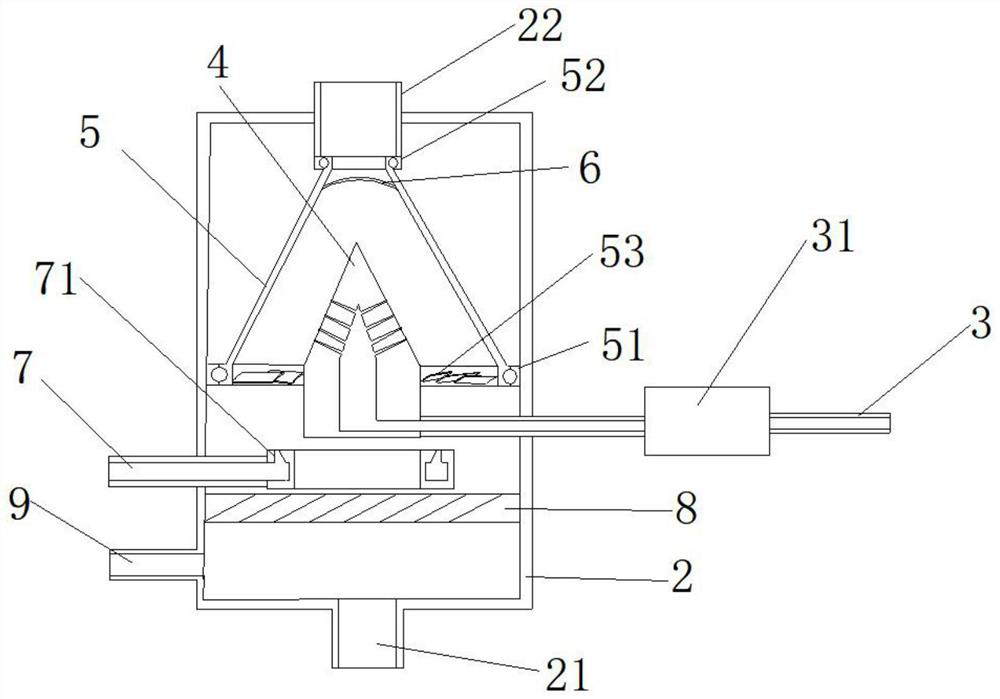

[0023] Please refer to figure 1 , figure 2 as well as image 3 ,in figure 1 A schematic structural view of a preferred embodiment of the energy-saving thermal deaerator provided by the present invention; figure 2 for figure 1 The structural sectional schematic diagram of the energy-saving thermal deaerator shown; image 3 for figure 2 A schematic cross-sectional view of the housing and the internal structure of the housing shown.

[0024] combined reference figure 1 and figure 2 As shown, an energy-saving thermal deaerator includes a cylindrical water tank 1. In the specific implementation process, the bottom surface of the water tank 1 is detachably fixed on the box body of the water tank. It is convenient for maintenance personnel to overhaul the energy-saving thermal deaerator. The top of the water tank 1 is provided with a barometer por...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap