A kind of silk with high light fastness and preparation method thereof

A technology of light resistance and silk, applied in the direction of silk reeling, silk fiber production, chemical post-treatment of fibers, etc., can solve the problems of easy yellowing, embrittlement, and mechanical properties decline of silk, achieve good color, reduce wear and tear, reduce The effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

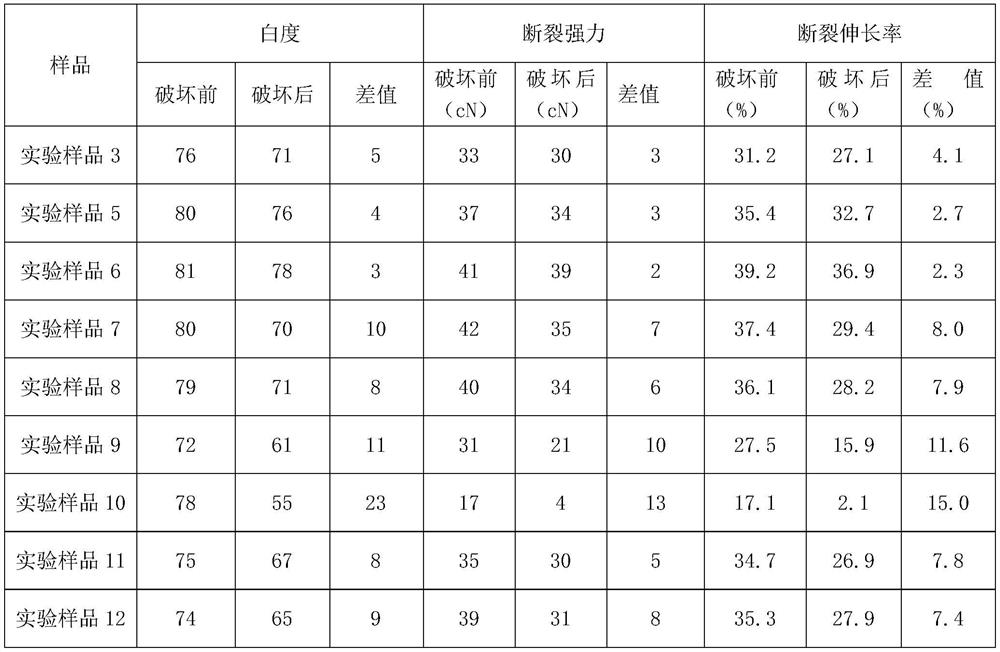

Examples

Embodiment 1

[0032] A preparation method of high light fastness silk, comprising the following steps:

[0033] a. According to the weight ratio, take 19 parts of silkworm cocoons, after boiling the cocoons, add 55 parts of protective agent, and soak for 60 minutes under the conditions of vacuum degree of 20Pa and temperature of 40°C to obtain pretreated cocoons;

[0034] Wherein, the protective agent includes the following raw materials in parts by weight: 6 parts of white carbon black, 100 parts of water, 1 part of dodecyl glucoside, 12 parts of zein, 1 part of barium strontium titanate and 0.2 parts of sodium bicarbonate.

[0035]The preparation method of the protective agent is as follows: according to the weight ratio, take white carbon black, dodecyl glucoside and water and add them to a high-pressure homogenizer, homogenize 4 times at 80MPa, then add corn protein, strontium barium titanate, Sodium bicarbonate, continue to homogenize 3 times under 100MPa to obtain the protective agent...

Embodiment 2

[0042] A preparation method of high light fastness silk, comprising the following steps:

[0043] a. According to the weight ratio, take 35 parts of silkworm cocoons, after boiling the cocoons, add 75 parts of protective agent, and soak for 120 minutes at a vacuum degree of 40kPa and a temperature of 50°C to obtain pretreated cocoons;

[0044] Wherein, the protective agent includes the following raw materials in parts by weight: 10 parts of white carbon black, 140 parts of water, 3 parts of dodecyl glucoside, 16 parts of zein, 2 parts of barium strontium titanate and 1.2 parts of sodium bicarbonate.

[0045] The preparation method of the protective agent is as follows: according to the weight ratio, take white carbon black, dodecyl glucoside and water and add them to a high-pressure homogenizer, homogenize at 120MPa for 8 times, then add corn protein, strontium barium titanate, Sodium bicarbonate, continue to homogenize 5 times under 130MPa to obtain the protective agent.

[...

Embodiment 3

[0052] A preparation method of high light fastness silk, comprising the following steps:

[0053] a. Take 23 parts of silkworm cocoons by weight, boil the cocoons, add 60 parts of protective agent, and soak for 75 minutes at a vacuum degree of 25kPa and a temperature of 43°C to obtain pretreated cocoons;

[0054] Wherein, the protective agent includes the following raw materials by weight: 7 parts of white carbon black, 110 parts of water, 1.5 parts of dodecyl glucoside, 13 parts of corn gluten, 1.2 parts of barium strontium titanate and 0.5 parts of sodium bicarbonate.

[0055] The preparation method of the protective agent is as follows: according to the weight ratio, take white carbon black, dodecyl glucoside and water and add them to a high-pressure homogenizer, homogenize at 90MPa for 5 times, then add corn protein, strontium barium titanate, Sodium bicarbonate, continue to homogenize 4 times under 110MPa to obtain the protective agent.

[0056] b. Add penetration aid in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com