Printing and dyeing device and printing and dyeing process for high-color-fastness cotton yarn

A technology with high color fastness, printing and dyeing process, applied in the direction of dyeing method, equipment configuration for processing textile materials, liquid/gas/vapor yarn/filament processing, etc. To achieve the effect of good dyeing effect, good effect and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

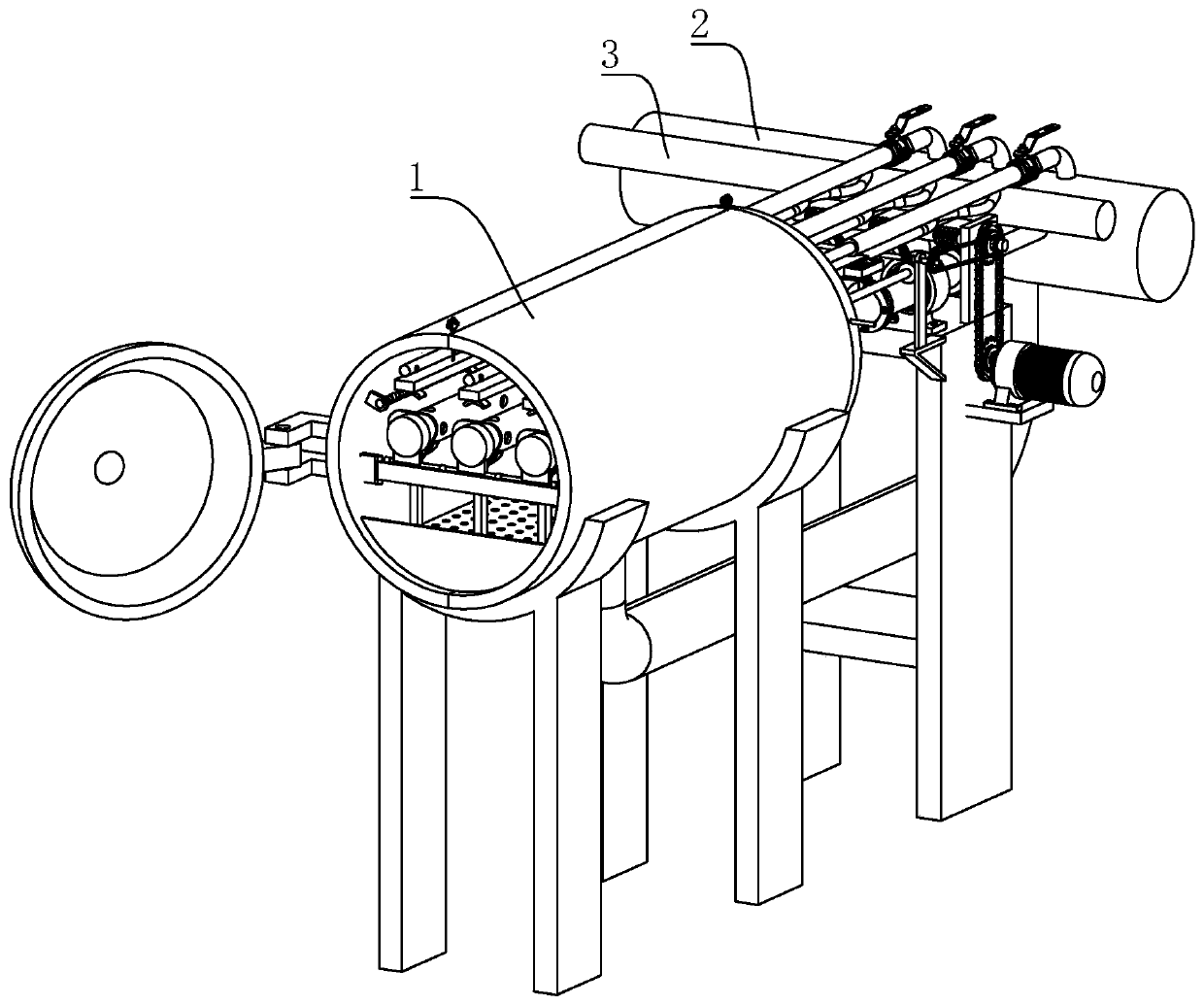

[0042] Embodiment: a kind of high color fastness cotton yarn printing and dyeing device, as figure 1 As shown, the dyeing vat body 1 is included, the dyeing vat body 1 is provided with a support frame, and one side of the dyeing vat body 1 is provided with a dye liquid delivery pipe 2 and a steam delivery pipe 3, and the dye liquid delivery pipe 2 can deliver dye, steam The conveying pipe 3 can act on the skein yarn while dyeing, so that the dyeing effect is better.

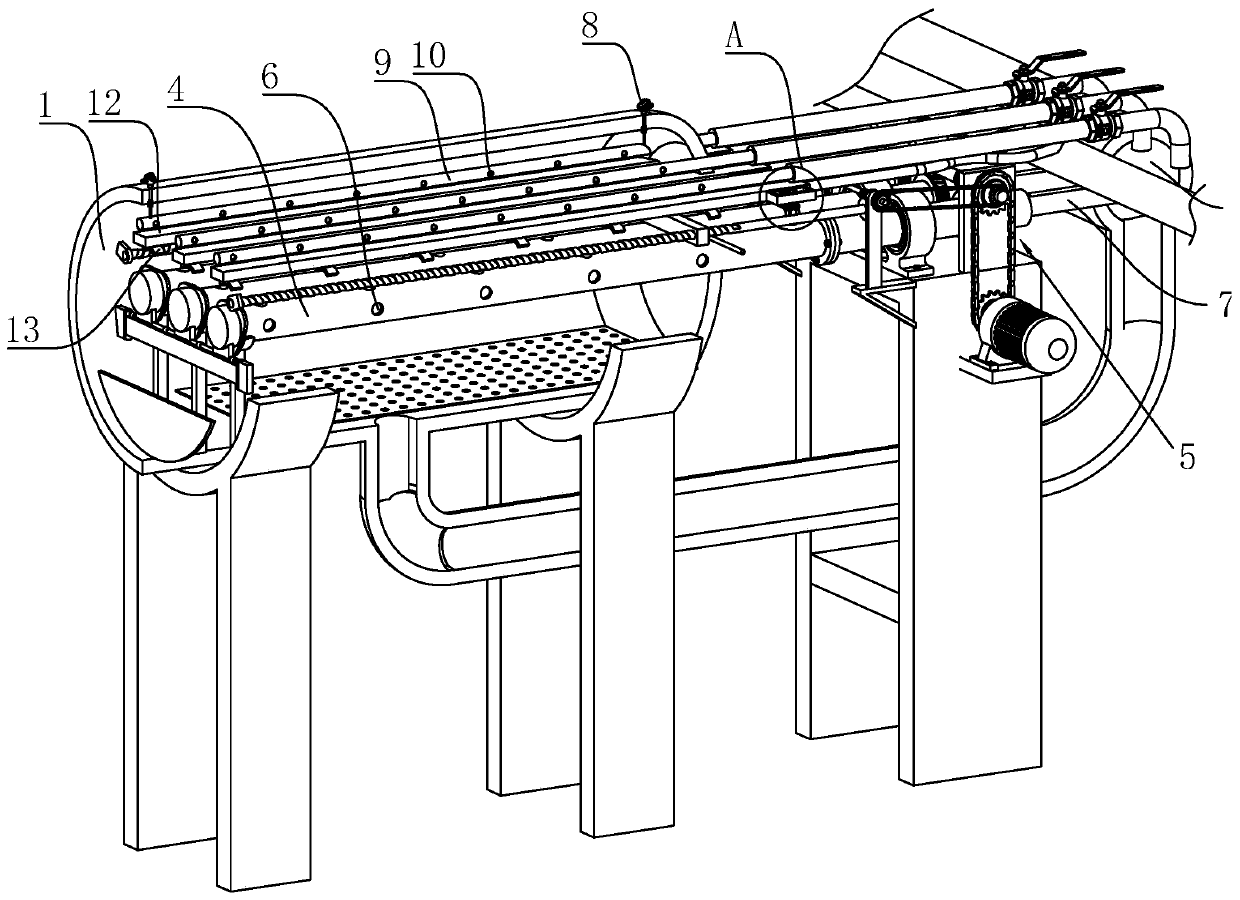

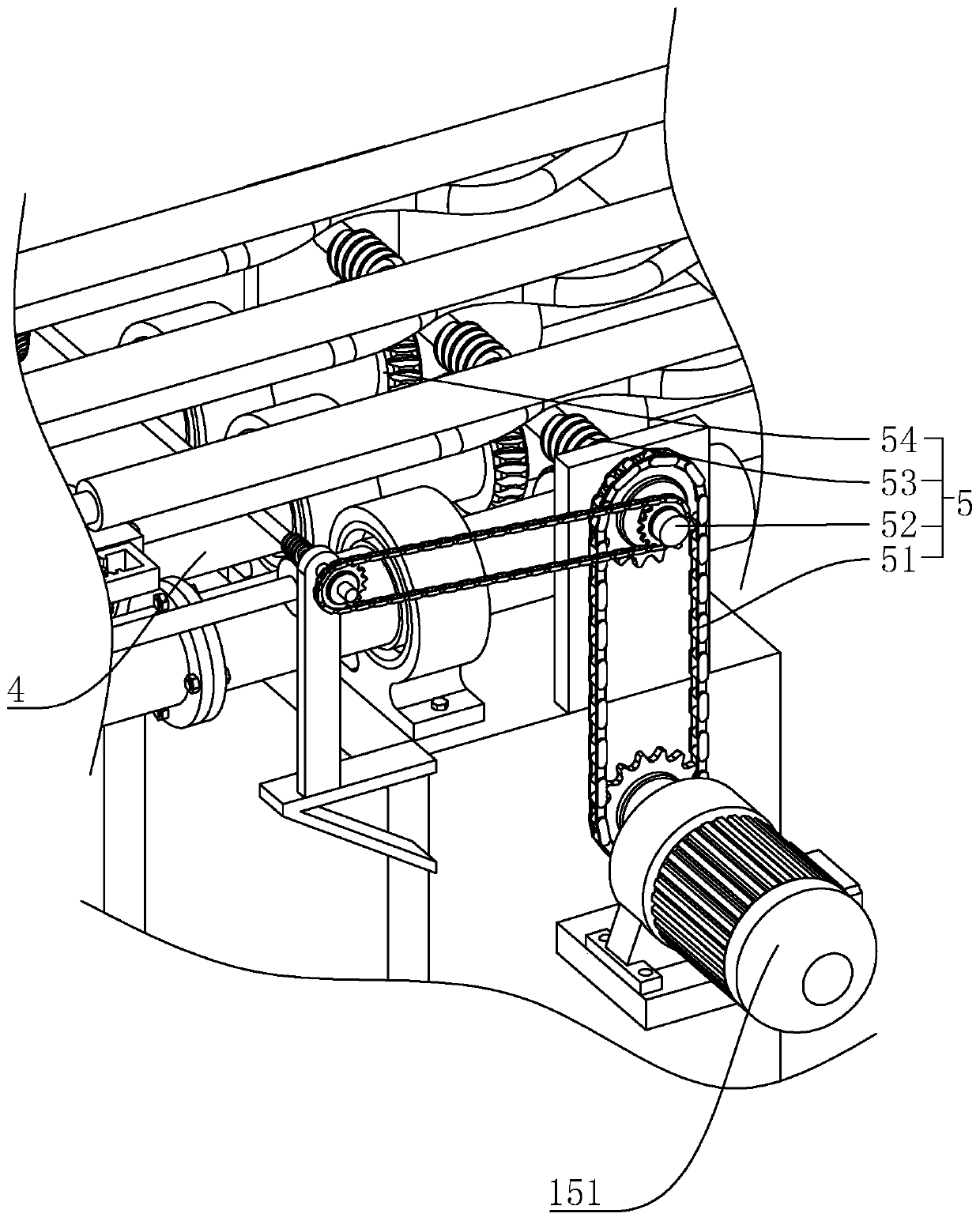

[0043] Such as figure 2 As shown, the dyeing vat body 1 is rotatably connected with a skein frame 4, and the skein frame 4 is rotated in conjunction with the first drive assembly 5. A through hole 6, one end of the skein frame 4 communicates with a dye pipe 7, the dye pipe 7 communicates with the dye liquid delivery pipe 2, the first drive assembly 5 links the skein frame 4 to rotate, and the dye pipe 7 is in the skein frame 4 The dye solution is passed through, and the dye solution acts on the skein through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap