Fabricated anti-seismic internal parting wall and mounting method thereof

An installation method and technology of internal partition walls, applied in walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of increasing the cost of materials and occupying the usable area of the house, so as not to occupy space, avoid potential safety hazards, and reduce The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

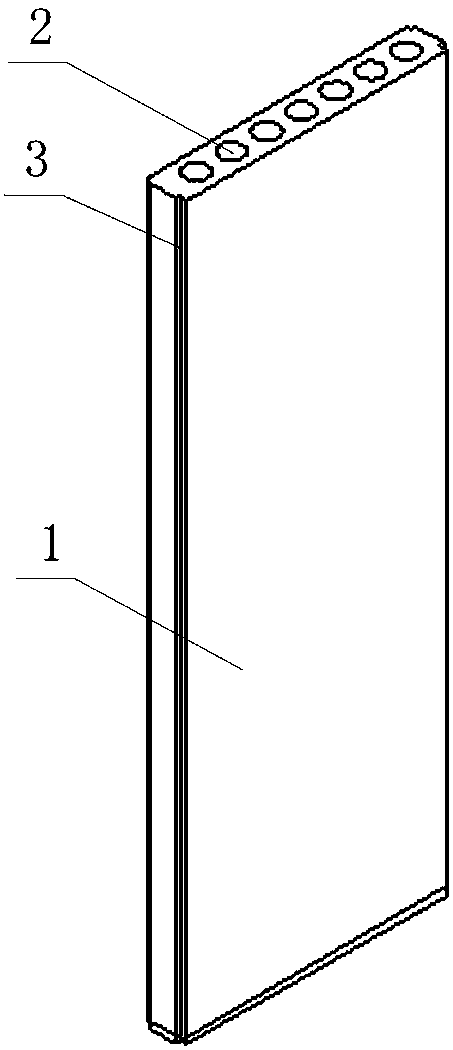

[0029] Such as Figure 1-7 As shown, a prefabricated anti-seismic inner partition wall includes a plurality of lightweight slats 1, the interior of the lightweight slats 1 is provided with a hollow groove 2 along the long side direction, and the lightweight slats 1 are arranged along the long side direction The side edge is provided with a groove 3, and the hollow groove 2 is parallel to the groove 3. The cross-section of the hollow groove 2 is circular or polygonal. The design of the hollow groove 2 not only ensures the hollow ratio of the anti-seismic inner partition wall stipulated by the state, but also saves materials; the groove 3 is designed for fixing.

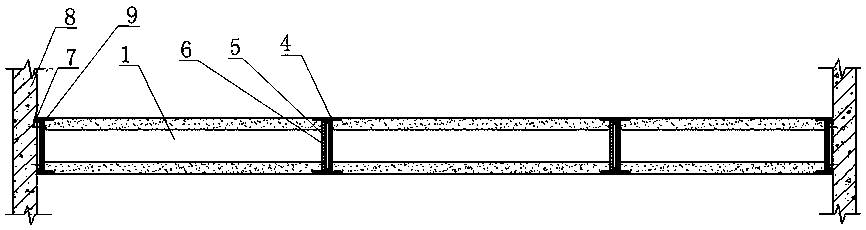

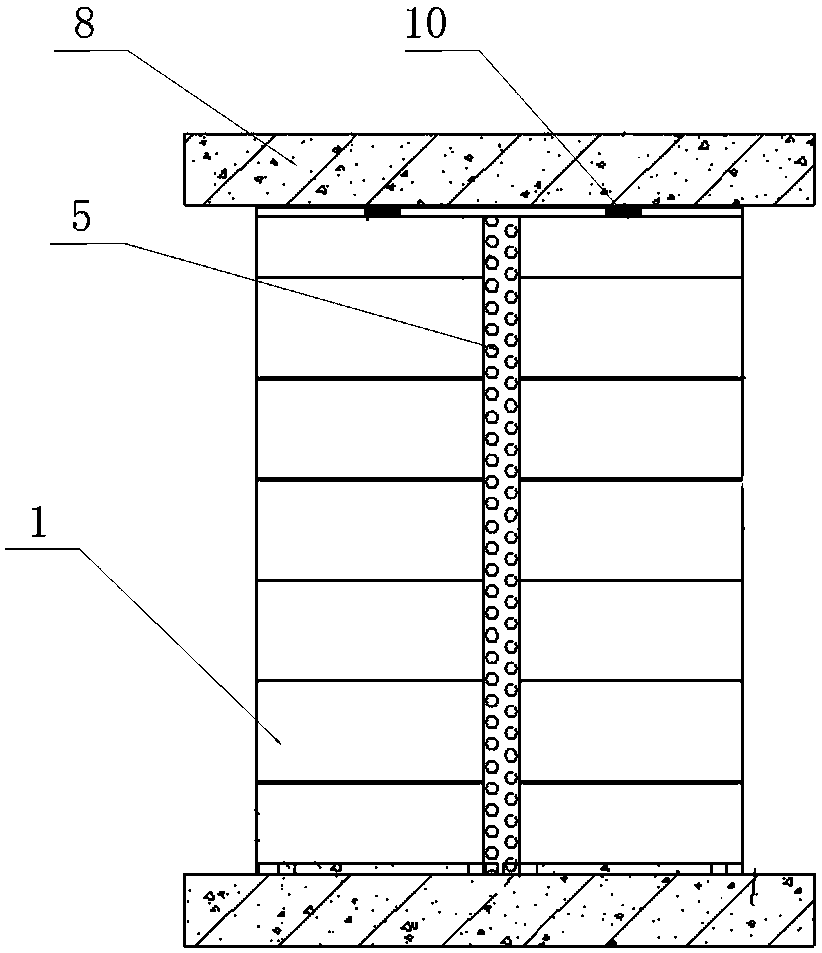

[0030] The lightweight slats 1 are combined and installed horizontally to form an inner partition wall panel, and a square steel column I9 for connection is provided between the inner partition wall panel and the main structure 8, and between the adjacently installed lightweight slats 1 in the inner partition wall pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com