Bolt assembly for automobile hub

A technology of bolt assembly and automobile wheel hub, applied in the direction of bolts, threaded fasteners, screws, etc., can solve the problems of large impact and vibration of tire nuts, loose tire nuts, etc., to increase friction and facilitate replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

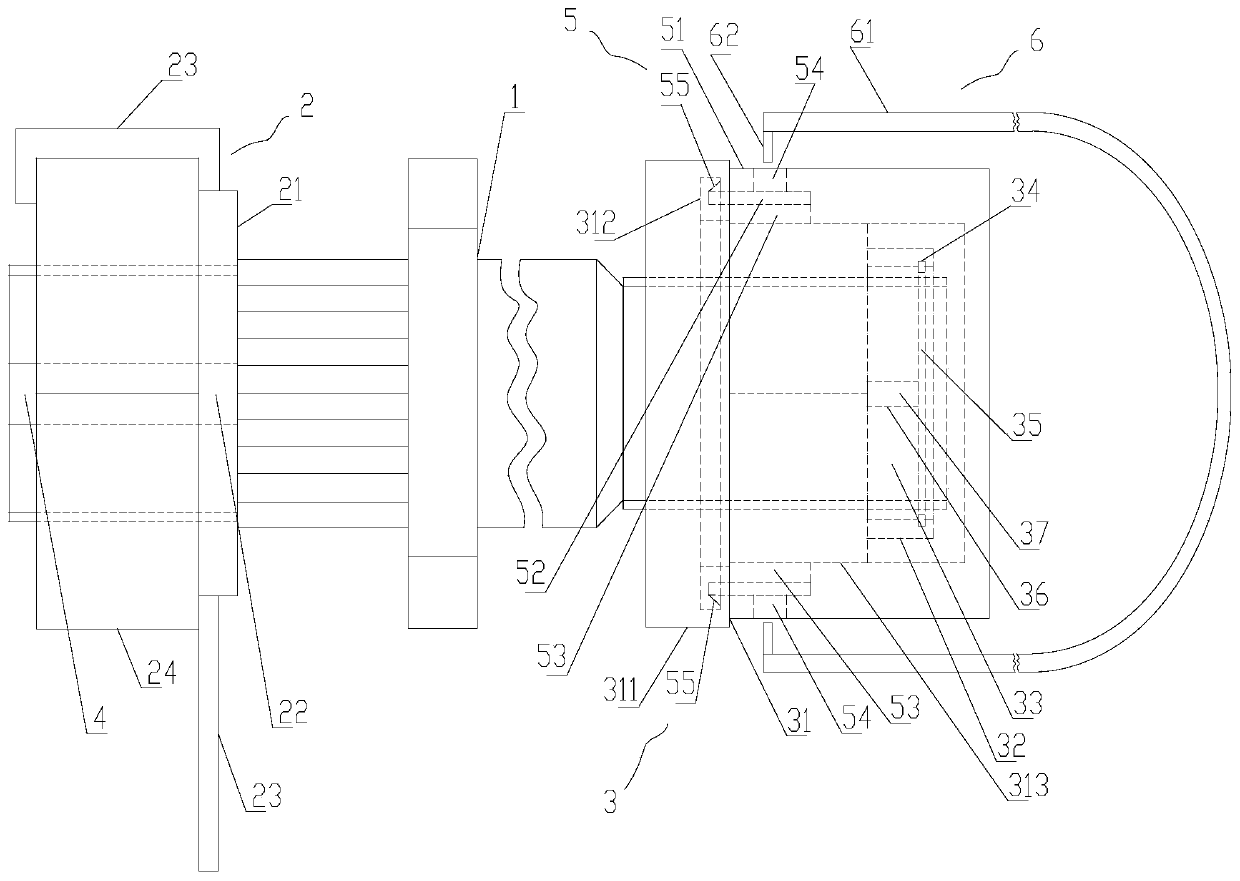

[0021] refer to figure 1 , a bolt assembly for an automobile wheel according to the present invention, comprising a stud bolt 1, a hub nut assembly 2 and a wheel nut assembly 3, the front threaded portion of the stud bolt 1 is provided with a hub nut assembly 2, and the stud bolt 1 is provided with a hub nut assembly 2. The rear threaded part of the bolt 1 is provided with a hub nut assembly 3, the hub nut assembly 2 includes a spacer 21, a positioning body 22, several fixed bodies 23 and nuts 24, and the front threaded part of the stud bolt 1 is covered A spacer 21 and a threaded nut 24 are provided. The nut 24 presses against the front end of the spacer 21. The inner wall of the spacer 21 is provided with a positioning body 22. The bolt 1 is provided with a positioning body 22 Matching positioning groove 4, the pad 21 is provided with uniformly distributed fixed body 23, the fixed body 23 is deformable and can maintain the deformed shape, and the fixed body 23 is deformed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com