Smelting furnace

The technology of a melting furnace and a gas storage tank, which is applied in the field of metallurgical melting, can solve the problems of reducing the volume of the melting furnace, high cost, high price of refractory bricks, etc., and achieves the effect of improving work efficiency and reducing heat insulation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in combination with specific embodiments.

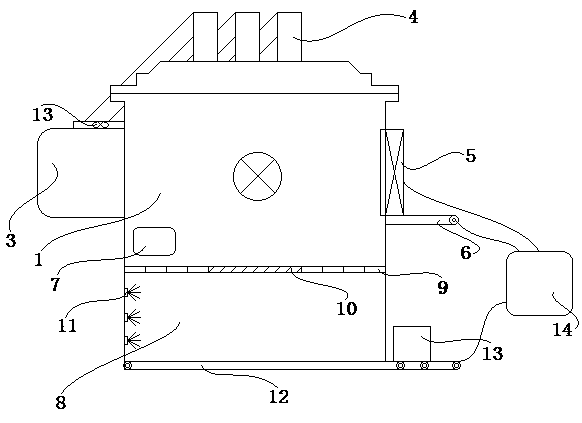

[0017] Such as figure 1 Shown is a smelting furnace, a smelting furnace, comprising a smelting bin 1, a vent 2, an air storage tank 3, an air duct 4 and a motor 14, the vent 2 is arranged on one side of the smelting bin 1, and the feed port It is arranged on the other side of the smelting bin 1 , and the gas outlet of the gas storage tank 3 is connected with the smelting bin 1 through the ventilation pipe 4 . An air pressure regulating valve 13 is arranged at the gas outlet of the gas storage tank 3, and the gas stored in the gas storage tank 3 is carbon monoxide.

[0018] A steel breaker 5 is set at the feed inlet of the smelting furnace 1 , a conveyor belt A6 is set at the bottom of the steel breaker 5 , and a molten metal temperature measuring instrument 7 is set on the inner side wall of the smelting bin 1 .

[0019] A pre-cooling bin 8 is arranged below the smelting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com