A Method for Measuring and Calculating Spalling Width of Bearing Inner Raceway

A technology for inner raceways and bearings, which is applied in the field of measurement and calculation of the spalling width of the inner raceway of bearings, can solve the problems of difficulty in accurate measurement and calculation of inner raceway spalling, and the inability to distinguish inner raceway spalling, etc., achieving important practicality and engineering value, The effect of preventing serious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The calculation method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, the scope of protection of the invention is not limited to the examples described.

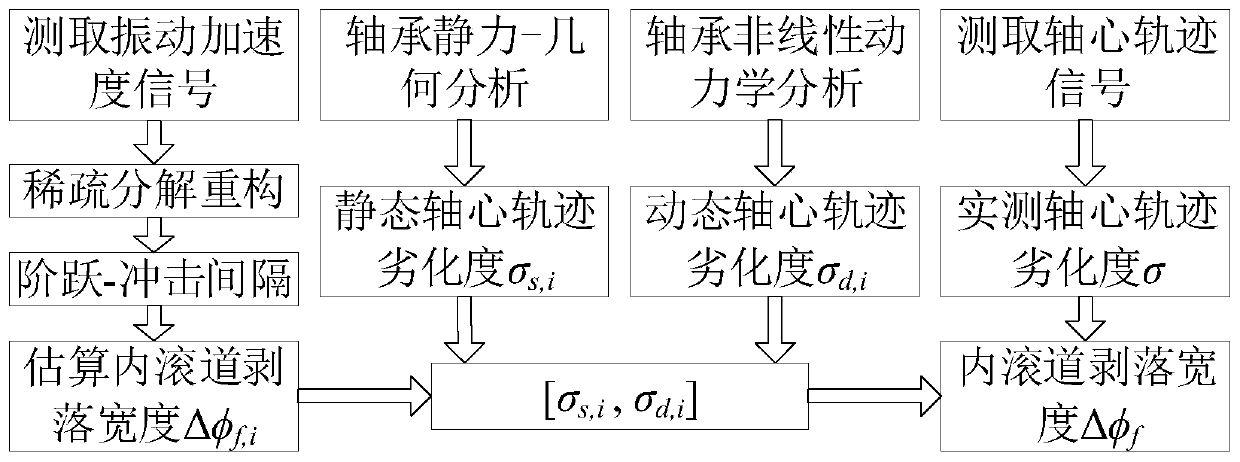

[0038] Step 1, Preliminary estimation of spalling width of bearing inner raceway:

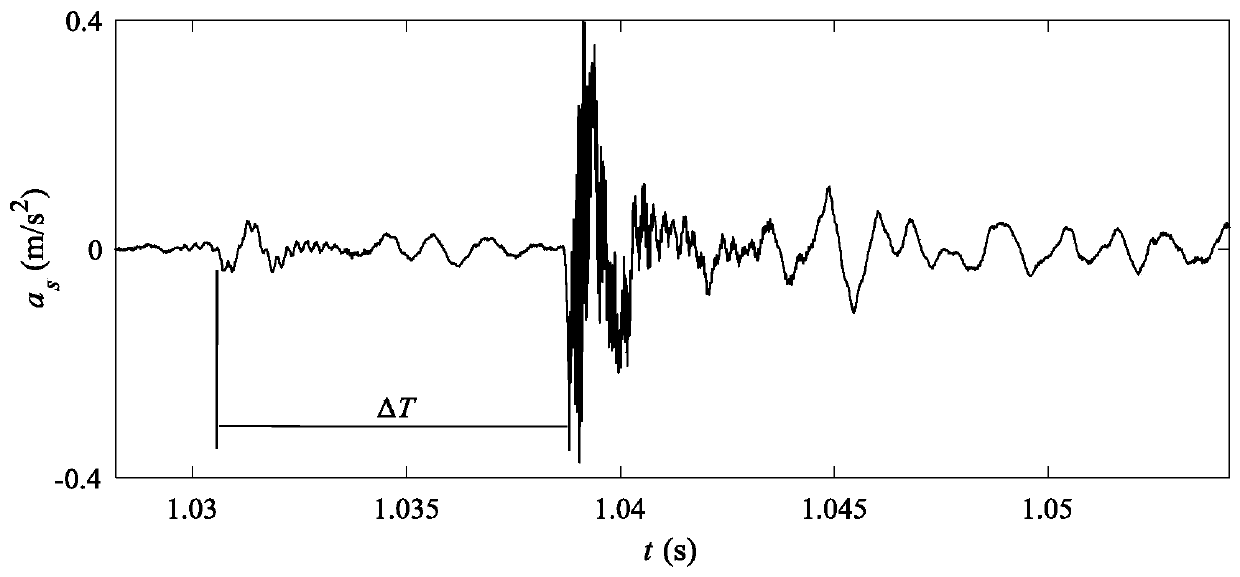

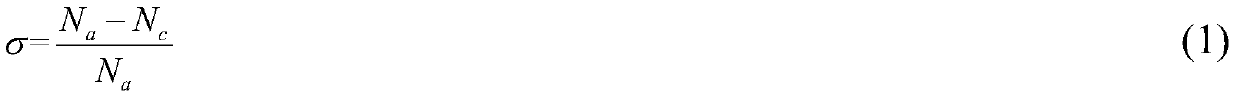

[0039] The eddy current displacement sensor is used, and the acquisition time is T n , the number of data points is N a The horizontal vibration displacement signal x of the bearing without fault s,0 (t) and vertical vibration displacement signal y s,0 (t); the reacquisition time is T n , the number of data points is N a The horizontal direction vibration displacement signal x of inner raceway spalling bearing to be measured s (t) and vertical vibration displacement signal y s (t); at the same time, the vibration acceleration sensor is used, and the acquisition time is T n , the number of data points is N a The vibration acceleration signal a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com