System for accurately measuring and automatically correcting liquid level of absorber oil regenerator in crude benzene coking unit

A technology for coking crude benzene and regenerator, which is applied in liquid/fluid solid measurement, measuring device, liquid level control, etc. Accurate control of liquid level and other issues, to achieve the effect of long life, improved adaptability, and small investment in instrumentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

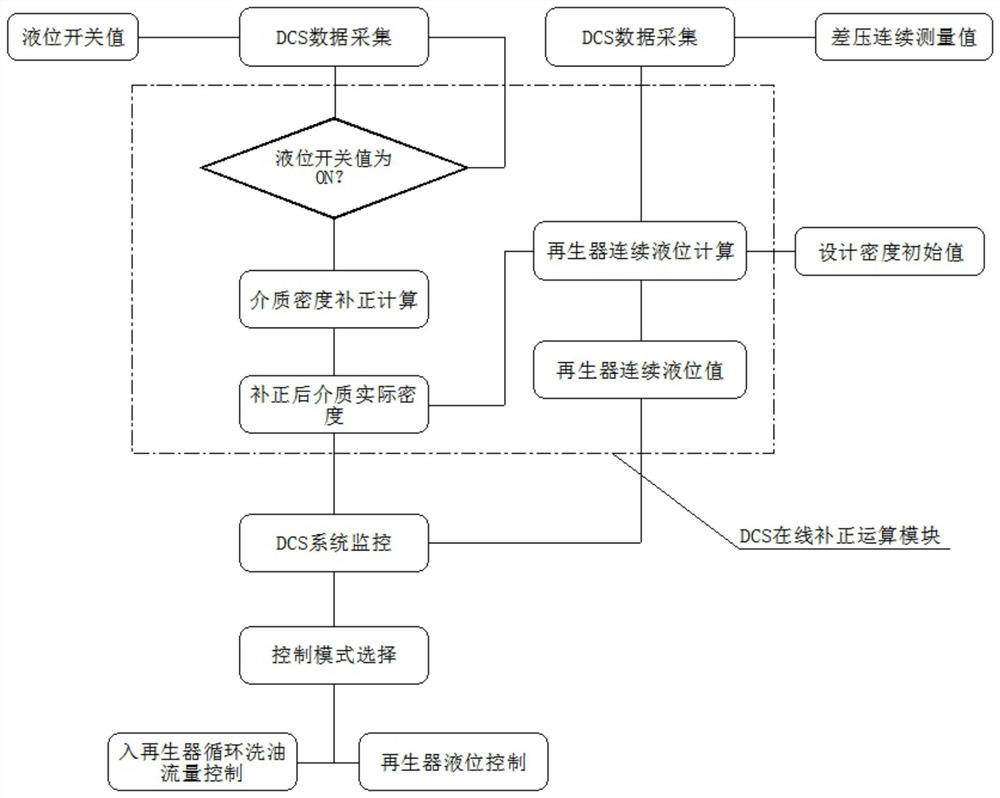

[0023] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

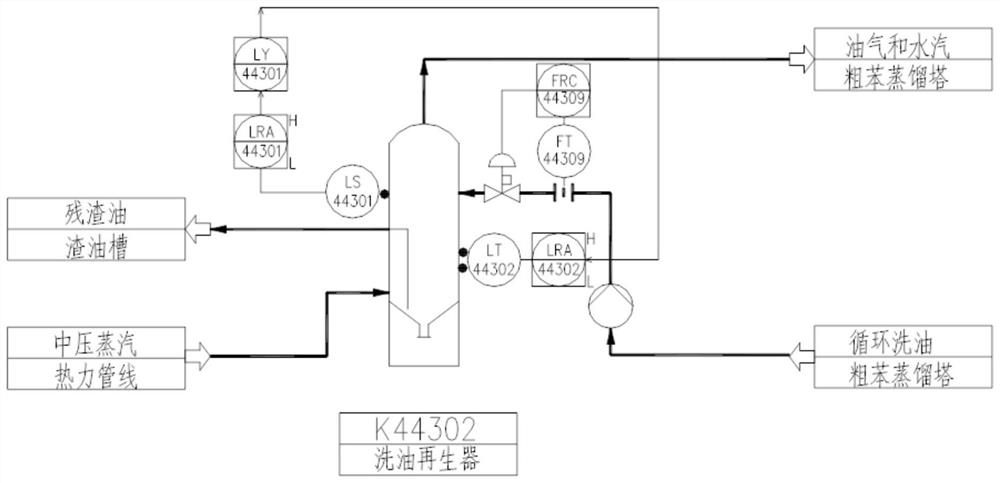

[0024] like figure 1 As shown, a coking crude benzene unit wash oil regenerator liquid level accurate measurement automatic correction system, including liquid level transmitter transmitter LT44302 and liquid level switch LS44301; differential pressure transmitter LT44302 and liquid level switch LS44301 and DCS The system is connected. ○ in the figure represents the field instrument, Expressed as a signal into DCS, LY indicates liquid level compensation.

[0025] The liquid level transmitter LT44302 is installed at the bottom of the oil washing regenerator for real-time measurement of the liquid level of the regenerator. The liquid level transmitter described above is a double-flange liquid level transmitter, and a pressure transmitter is used at the interface to measure the liquid level. The liquid level of the storage tank i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com