Passive ejection of fuel spheres as a high temperature reactor core for the second shutdown system

A technology of shutdown system and fuel ball, applied in the field of high temperature reactor core, can solve the problems affecting the power and life of advanced high temperature reactor with pebble bed, limiting the economy of advanced high temperature reactor with pebble bed, reducing the number of control rods, etc. The effect of improving economy and safety, reducing reactivity, and reducing the amount of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

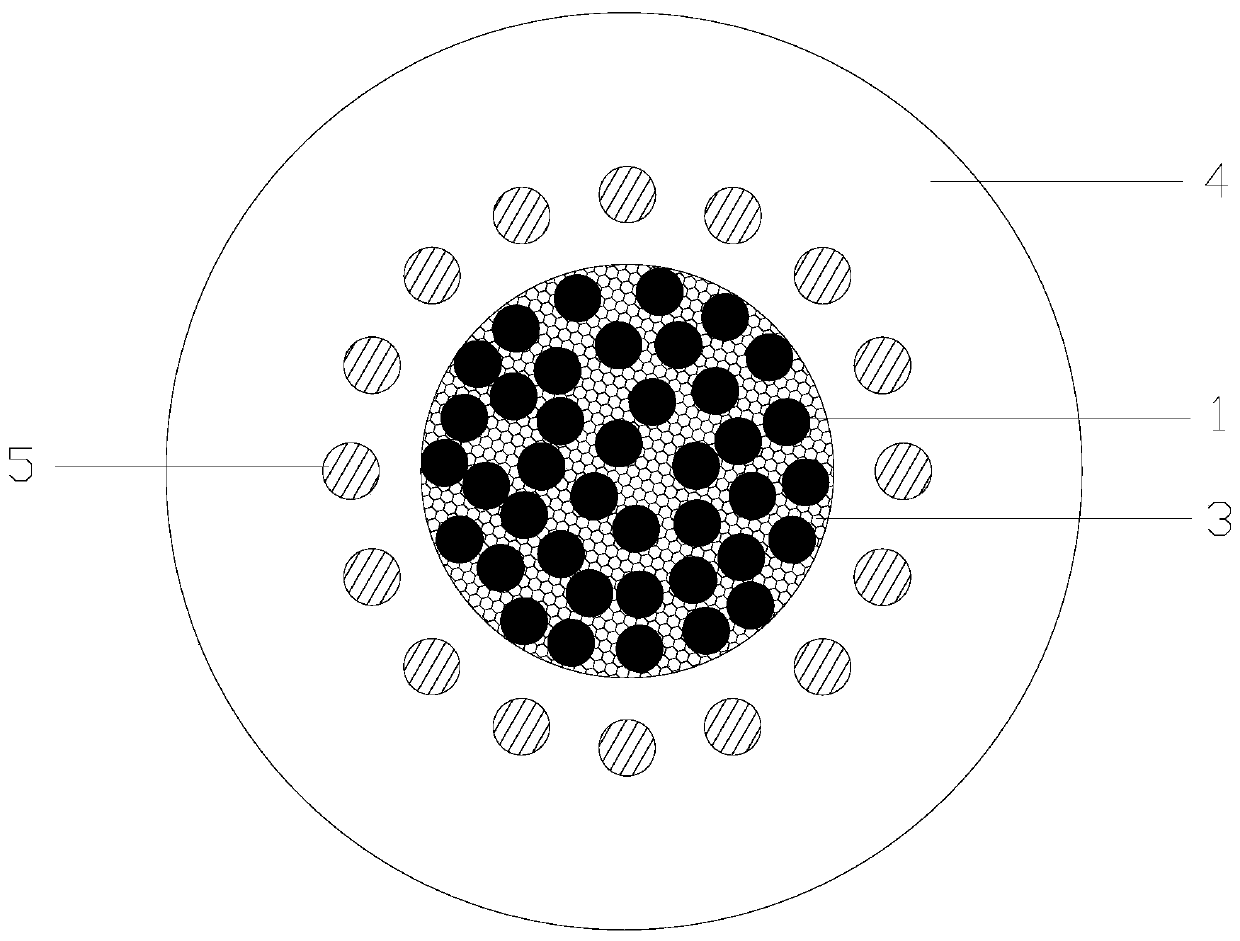

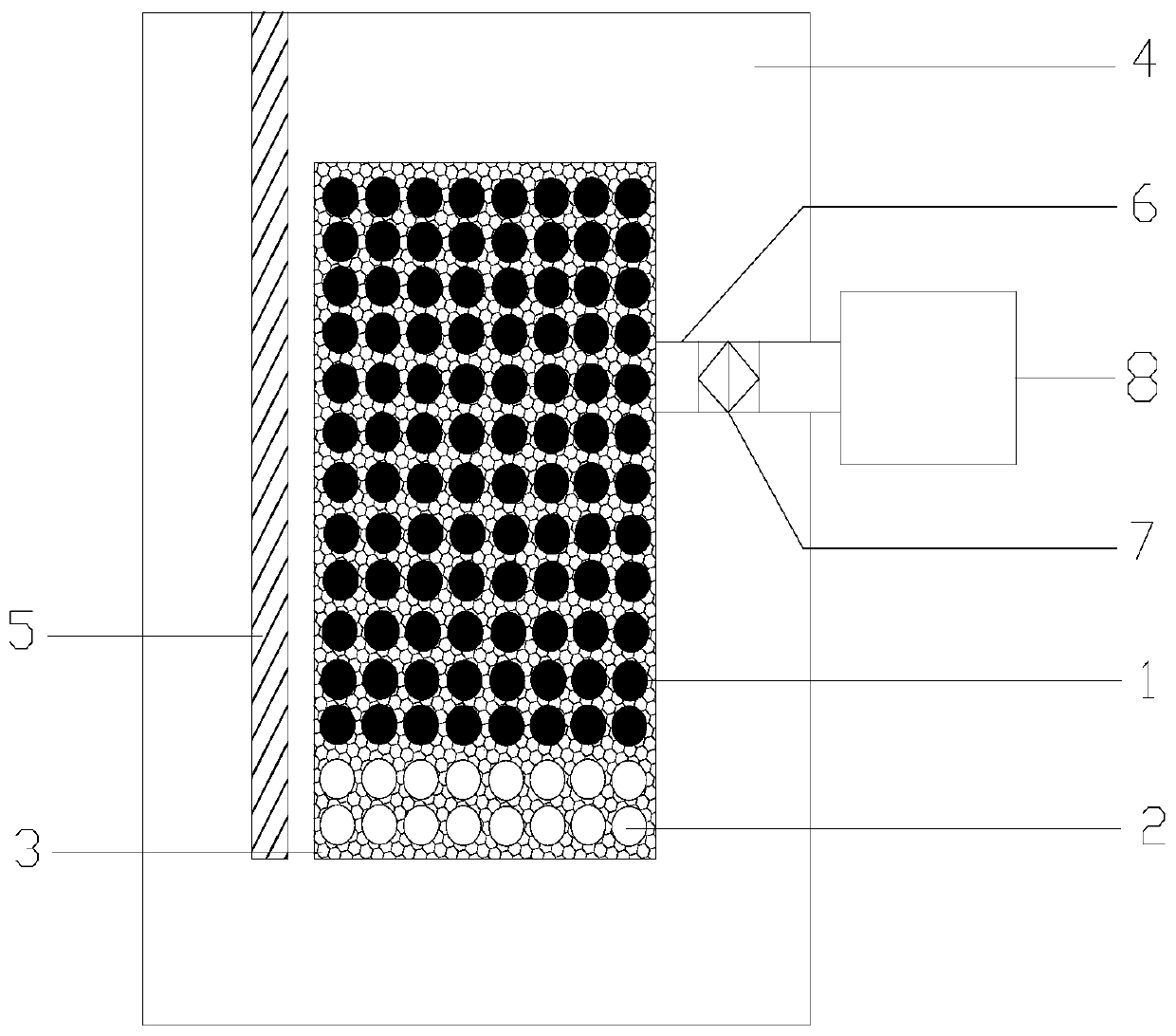

[0024] Such as figure 1 with figure 2 As shown, this embodiment provides an advanced high temperature reactor core that uses the principle of thermal expansion and contraction of molten salt to discharge fuel balls as the second set of shutdown system, including fuel balls 1, graphite balls 2, molten salt coolant 3. Graphite reflection layer 4, control rod 5, conduit 6, one-way pressure reducing valve 7, fuel storage tank 8. A plurality of fuel balls 1 are arranged at the upper part of the core active area; a plurality of graphite balls 2 are arranged next to the fuel balls 1 at the lower part of the core active area to play a role of fixing and filling; except for the fuel balls 1 and graphite balls 2, the core The remaining space in the active area is filled with molten salt coolant 3; the active area of the core is wrapped by a graphite reflective layer 4; multiple control rods 5 are arranged in the graphite reflective layer 4 near the periphery of the active area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com