Pipeline optical power cable laying power assisting device

A power-assisted device and photoelectric technology, applied in the direction of optical fiber/cable installation, cable laying equipment, etc., can solve the problem of inconvenient laying of optical cables or guide wires, etc., to achieve the effect of increasing stability and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

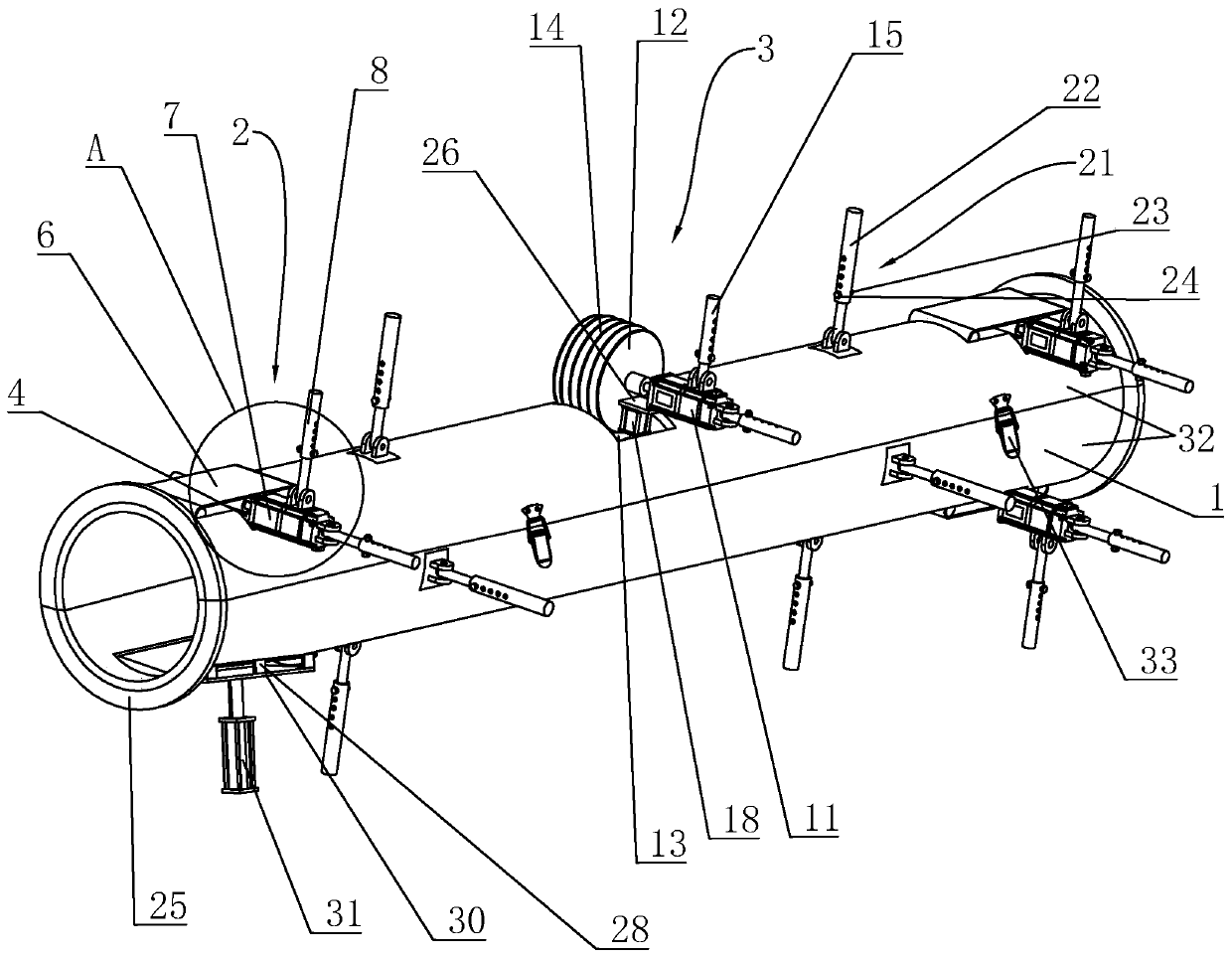

[0038] Embodiment: A kind of pipeline optical cable laying assistance device, refer to figure 1, including a multi-section flexible hose 1, the hose 1 is composed of two split parts 32. During installation, the operator splices the two split bodies 32 together correspondingly, and fixes the two split bodies 32 together through buckles 33 to form the hose 1 .

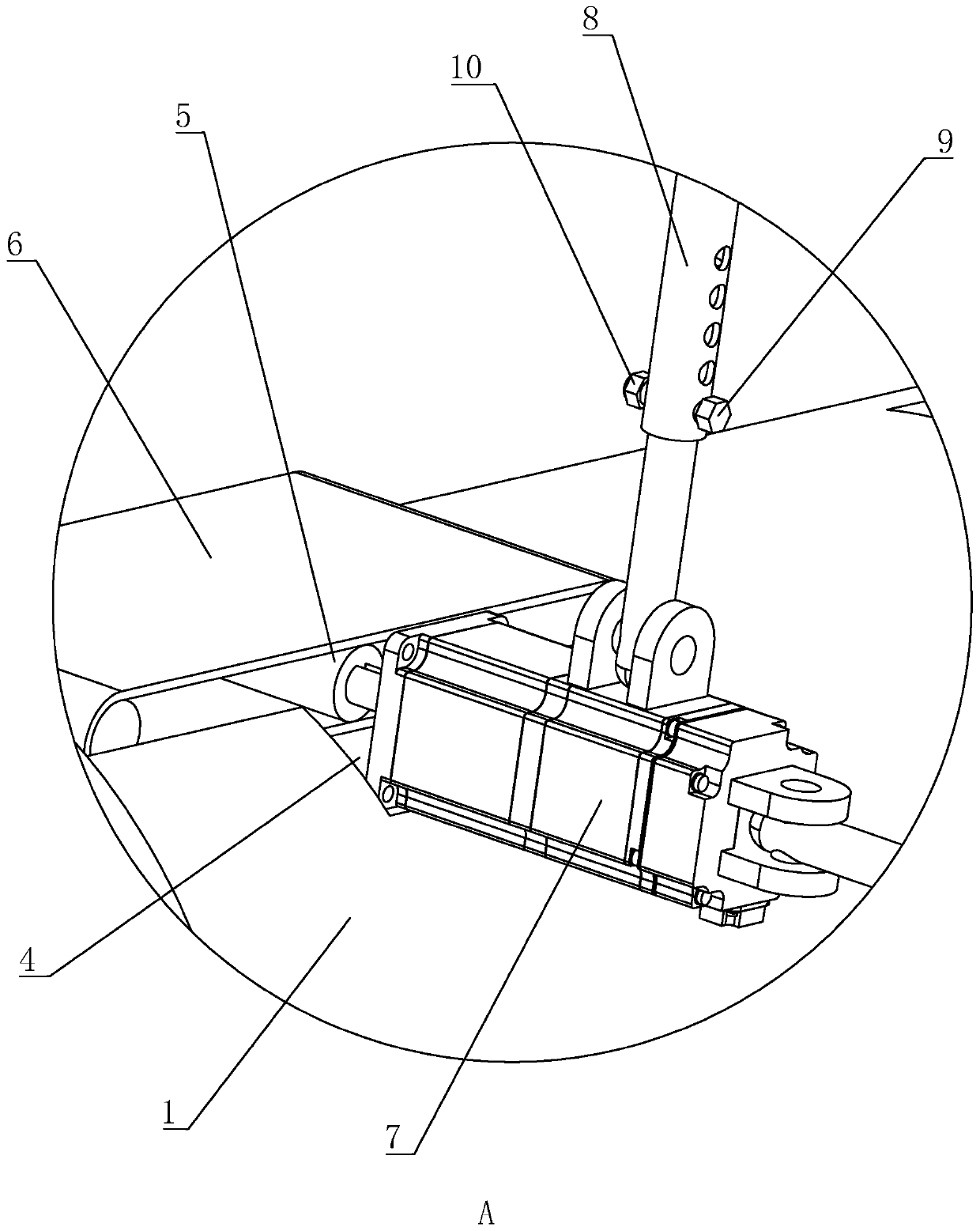

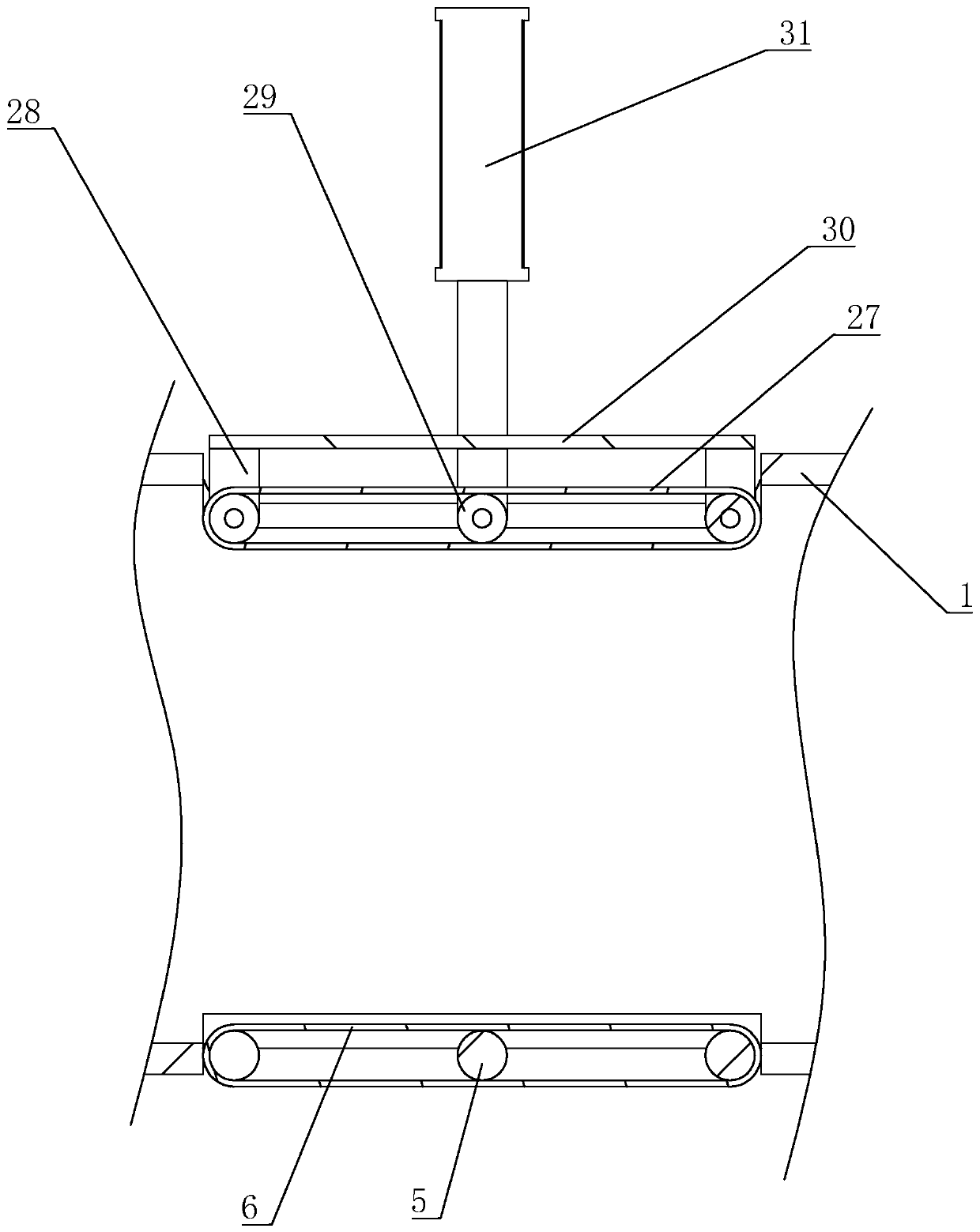

[0039] refer to figure 1 , The two ends of the hose 1 are welded with positioning rings 25 , and the positioning rings 25 are surrounded by two semicircular ring blocks on the outer periphery of the hose 1 . The setting of the positioning ring 25 plays a role of supporting and shaping the end of the hose 1 and enhances the stability of the overall structure of the hose 1 . The circumferential side of the hose 1 is provided with a telescopic support assembly 21. There are multiple sets of telescopic support assemblies 21 in the axial direction of the hose 1. The telescopic support assembly 21 includes a positioning supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com