A ring-shaped copper-aluminum composite heat sink stamping device

A technology of copper-aluminum composite and stamping device, which is applied in the field of stamping device and can solve the problems of loud impact sound and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

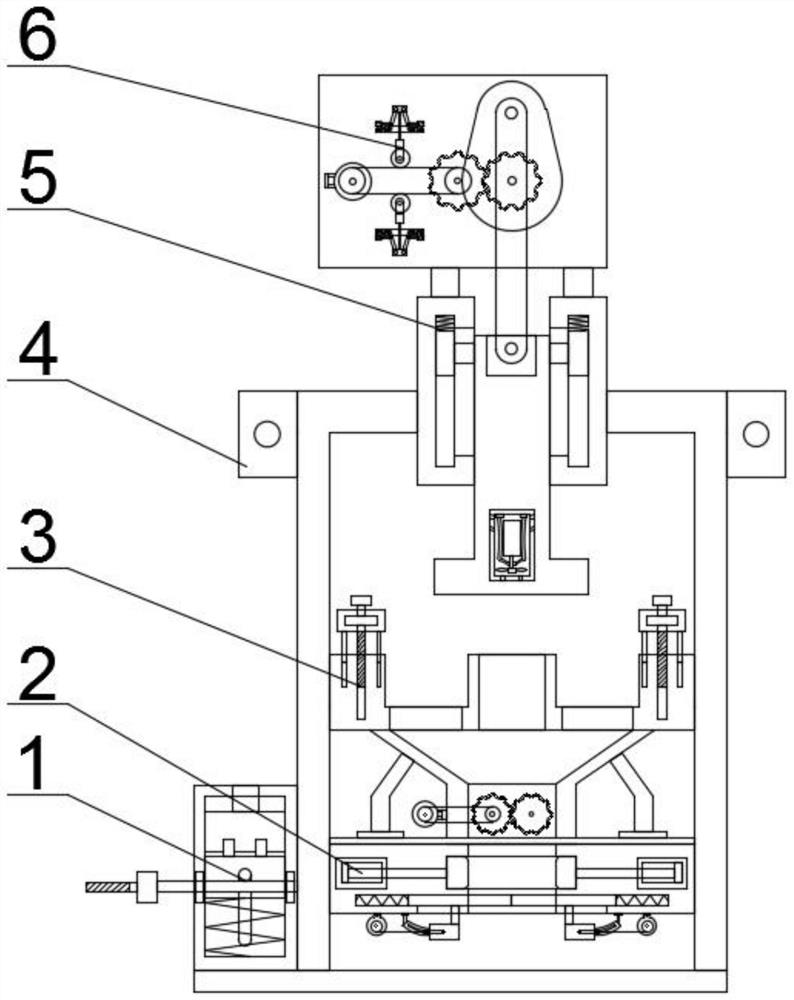

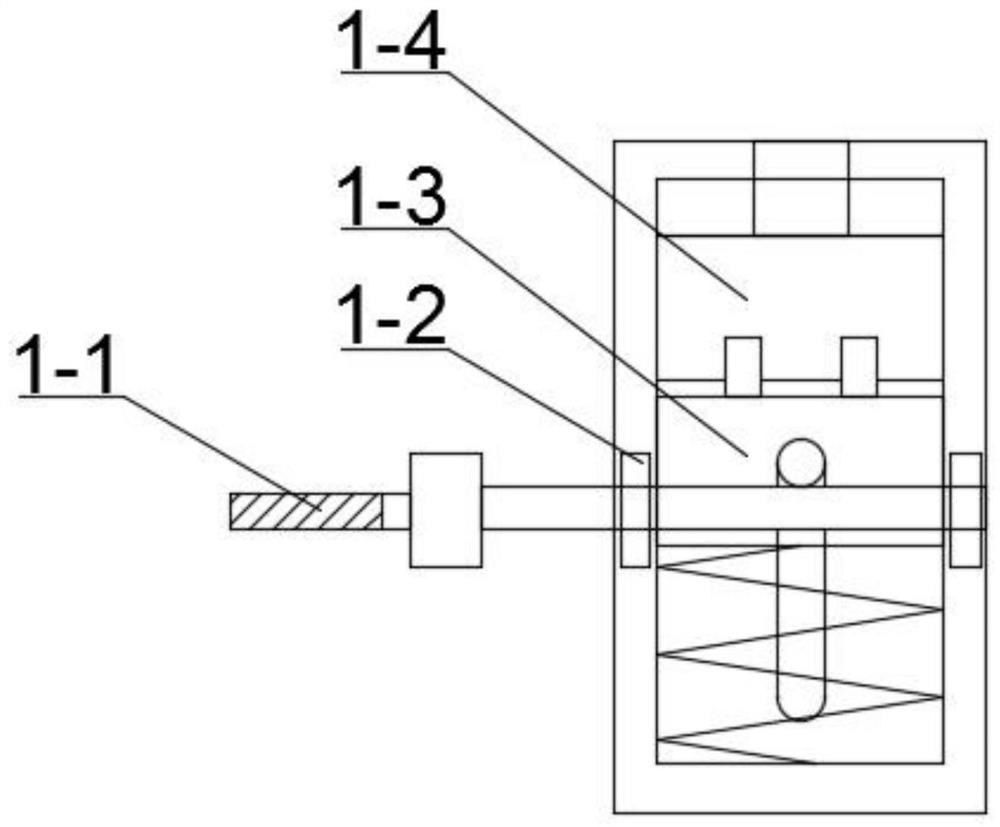

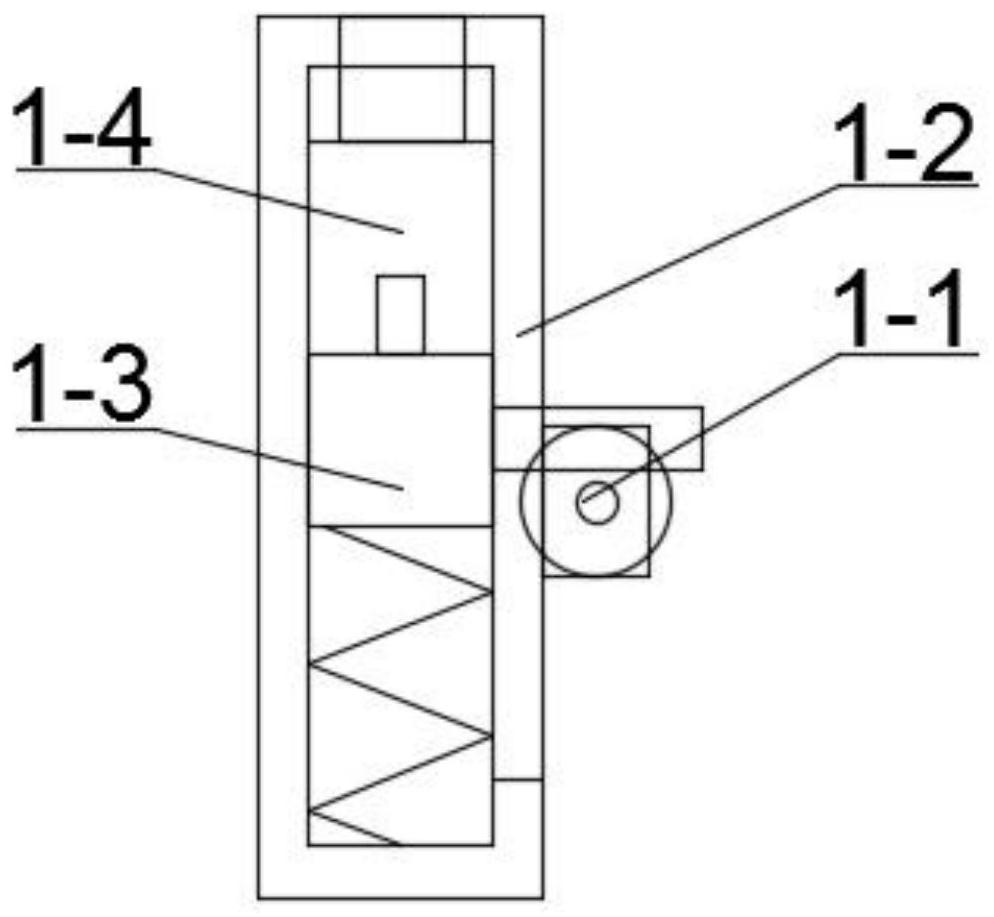

[0057] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 Describe the present embodiment, the present invention relates to a punching device, more specifically, a ring-shaped copper-aluminum composite heat sink punching device, including an emergency stop mechanism 1, a pressing block mechanism 2, a console mechanism 3, a bracket mechanism 4, a stamping Mechanism 5, tensioning mechanism 6, the device can provide power-off protection, the device can tension the belt, ensure the transmission of stamping kinetic energy, the device can clamp the workpiece, the device can perform stamping, and the device can prevent flying in the air during the stamping process. The foam scratches the workpiece, the device can crush ...

specific Embodiment approach 2

[0081] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 This embodiment will be described. This embodiment will further describe the first embodiment. The material of the pressure seat 2-1-4 is high manganese steel.

specific Embodiment approach 3

[0083] Combine below figure 1 , figure 2 , image 3, Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 This embodiment will be described. This embodiment will further describe Embodiment 1, and the number of the above-mentioned flow turbulence mechanisms 5-1 is two.

[0084] The device can provide power-off protection. During the stamping process, the kinetic energy of stamping is very large. If the operator is in danger or the device is in danger of short circuit, the insulating rod mechanism 1-1 can be pulled outward, and the insulating rod mechanism 1- After 1 is pulled out, it no longer plays a limiting role on the protrusion 1-3-2, and under the rebound action of the spring 1-2-2, the plug body 1-3-1 quickly moves downward and separates from the socket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com