Automatic multi-angle quick-assembling-disassembling tool

A multi-angle, tooling technology, applied in positioning devices, manufacturing tools, metal processing, etc., can solve the problems of not being able to choose a fixed angle, inconvenient and fast fixed installation, disassembly and replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

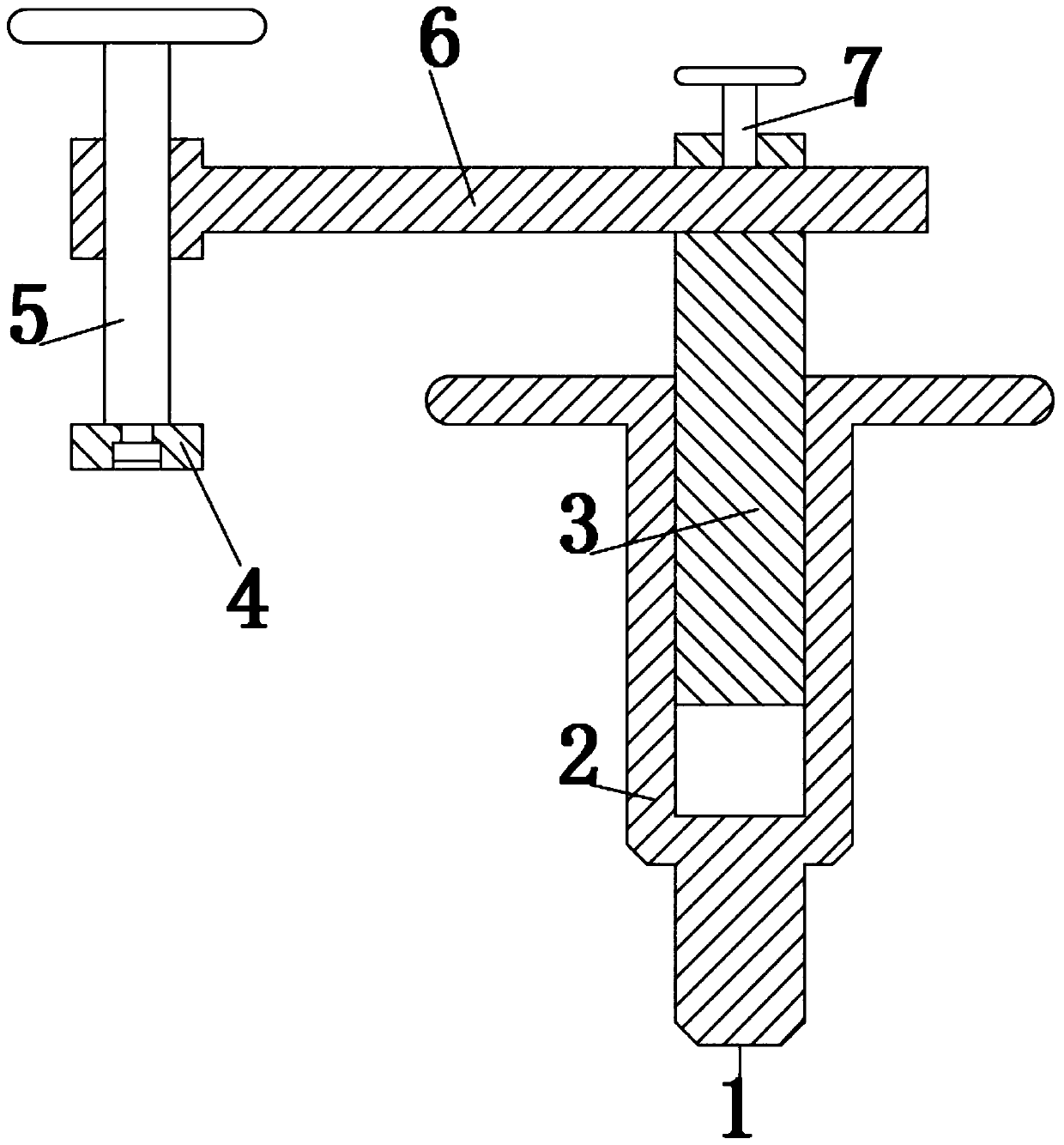

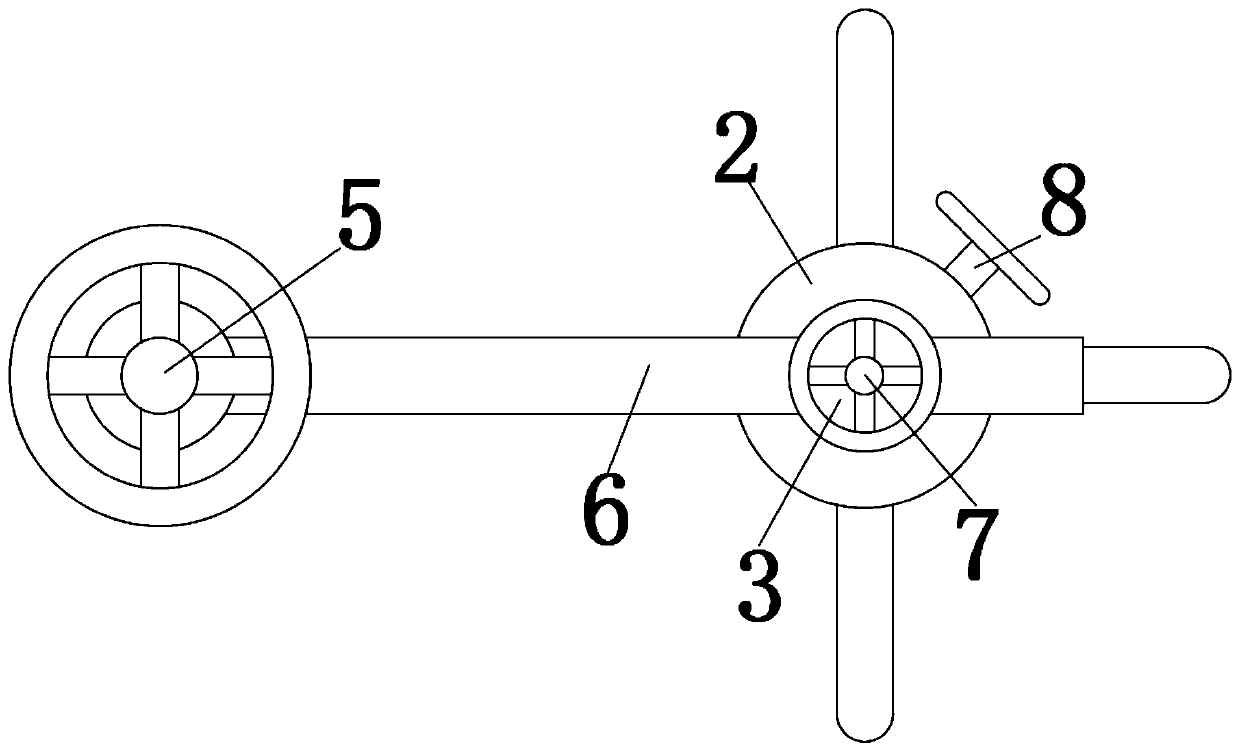

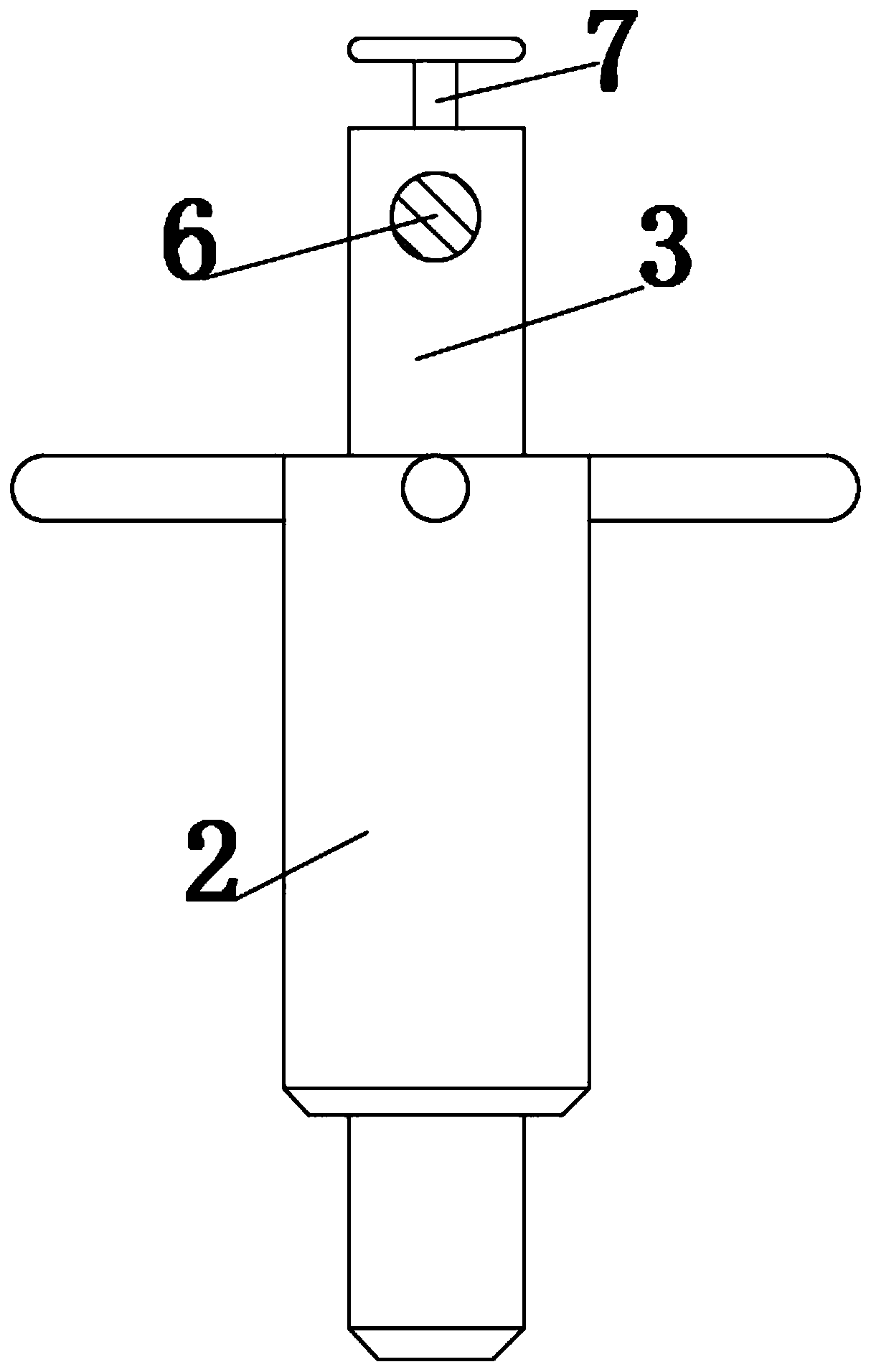

[0022] as attached figure 1 to attach image 3 Shown:

[0023] The present invention provides an automatic multi-angle fast change tooling, which includes a device body 1, a quick disassembly cylinder 2, a lifting and rotating column 3, a movable compression block 4, a compression fixing rod 5, a support adjustment rod 6, and an adjustment locking button 7 and the lifting locking button 8, the bottom of the device body 1 is provided with a quick disassembly tube 2 in the up and down direction, and the inside of the top of the quick disassembly tube 2 is locked and installed with a lifting and rotating column 3 through the upper lifting locking button 8 on the right rear; The top end of the lifting and rotating column 3 is inserted and installed with a support adjustment rod 6 to the right and is locked and fixed by the top adjustment locking button 7, and a compression fixing rod 5 is installed downwards inside the left end of the support adjustment rod 6; The bottom end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com