Low-carbon magnesium-carbon refractory material added with silicon magnesium nitride powder and preparation method thereof

A technology of carbon-magnesium-carbon refractories and silicon-magnesium nitride, which is applied in the field of low-carbon magnesium-carbon refractories, can solve the problems of unfavorable industrial production, increased production costs, and high addition of antioxidants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

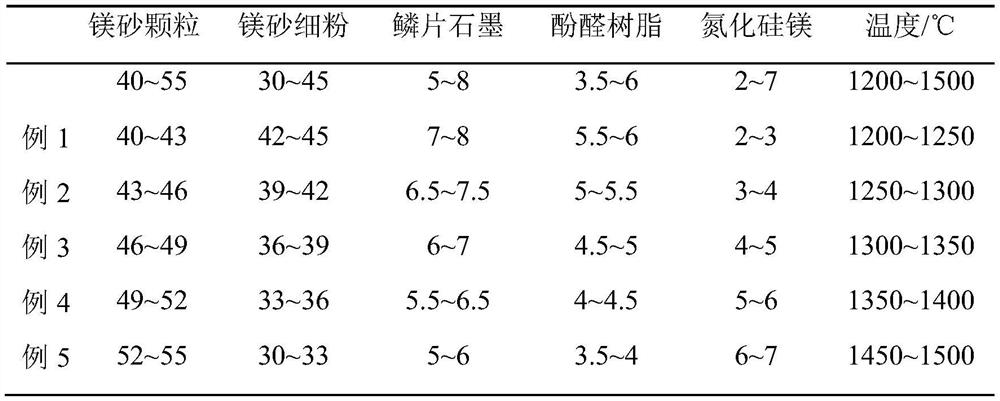

[0048] A low-carbon magnesium-carbon refractory material added with magnesium silicon nitride powder and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0049] Step 1. Use 40-43wt% fused magnesia particles, 42-45wt% fused magnesia fine powder, 7-8wt% flake graphite, 5.5-6wt% phenolic resin and 2-3wt% nitriding Magnesium silicon powder is used as raw material and ingredients.

[0050] Step 2. Add the magnesium silicon nitride powder into the phenolic resin in 3 to 5 times at 40 to 50° C. and under magnetic stirring conditions, and stir for 15 to 20 minutes each time to obtain a mixture, which is taken out for use.

[0051] Step 3. Under stirring conditions: first add the fused magnesia particles into the mixer, then add a mixture that accounts for 55 to 57 wt % of the mixture, and stir for 10 to 15 minutes; then add the fused magnesia fine powder, Stir for 10 to 15 minutes, then add the rest of the mixture, and stir for 10...

Embodiment 2

[0061] A low-carbon magnesium-carbon refractory material added with magnesium silicon nitride powder and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0062] Step 1. Use 43-46wt% fused magnesia particles, 39-42wt% fused magnesia fine powder, 6.5-7.5wt% flake graphite, 5-5.5wt% phenolic resin and 3-4wt% Magnesium silicon nitride powder is used as raw material and ingredients.

[0063] Step 2. Add the magnesium silicon nitride powder into the phenolic resin in 3 to 5 times at 40 to 50° C. and under magnetic stirring conditions, and stir for 15 to 20 minutes each time to obtain a mixture, which is taken out for use.

[0064] Step 3. Under stirring conditions: first add the fused magnesia particles into the mixer, then add the mixture accounting for 57-59 wt% of the mixture, and stir for 10-15 min; then add the fused magnesia fine powder, Stir for 10 to 15 minutes, then add the rest of the mixture, and stir for 10 to 15 min...

Embodiment 3

[0069] A low-carbon magnesium-carbon refractory material added with magnesium silicon nitride powder and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0070] Step 1. Using 46-49wt% fused magnesia particles, 36-39wt% fused magnesia fine powder, 6-7wt% flake graphite, 4.5-5wt% phenolic resin and 4-5wt% nitriding Magnesium silicon powder is used as raw material and ingredients.

[0071] Step 2. Add the magnesium silicon nitride powder into the phenolic resin in 3 to 5 times at 40 to 50° C. and under magnetic stirring conditions, and stir for 15 to 20 minutes each time to obtain a mixture, which is taken out for use.

[0072] Step 3. Under stirring conditions: first add the fused magnesia particles into the mixer, then add a mixture that accounts for 59 to 61 wt % of the mixture, and stir for 10 to 15 minutes; then add the fused magnesia fine powder, Stir for 10 to 15 minutes, then add the rest of the mixture, and stir for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com