Band knife structure of nap cutting machine

A technology of a velvet cutter and a knife, applied in the field of the velvet machine, can solve the problems of potential safety hazards, the operator is easy to be cut when disassembling the belt knife, etc., so as to improve the stability of movement, reduce the amplitude of jitter, and reduce the The effect of the degree of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings.

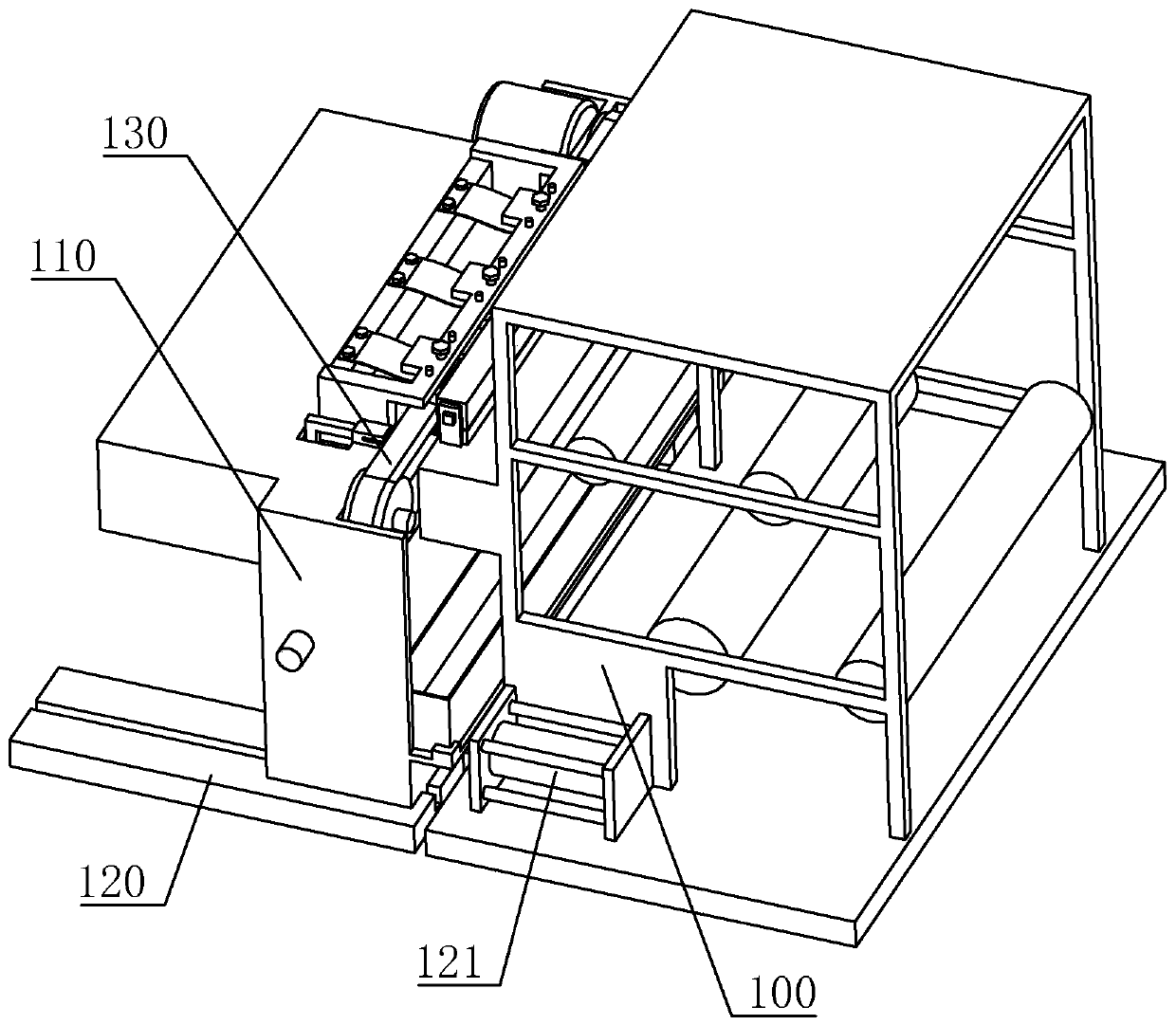

[0041] A structure with a knife 130 of a velvet cutting machine, refer to figure 1 , including a frame 100, one side of the frame 100 is slidably connected with a sliding frame 110, a slide rail 120 is installed on the lower side of the sliding frame 110, a sliding cylinder 121 is fixed on the frame 100 by bolts, and the sliding cylinder 121 The piston rod is fixedly installed on the sliding frame 110.

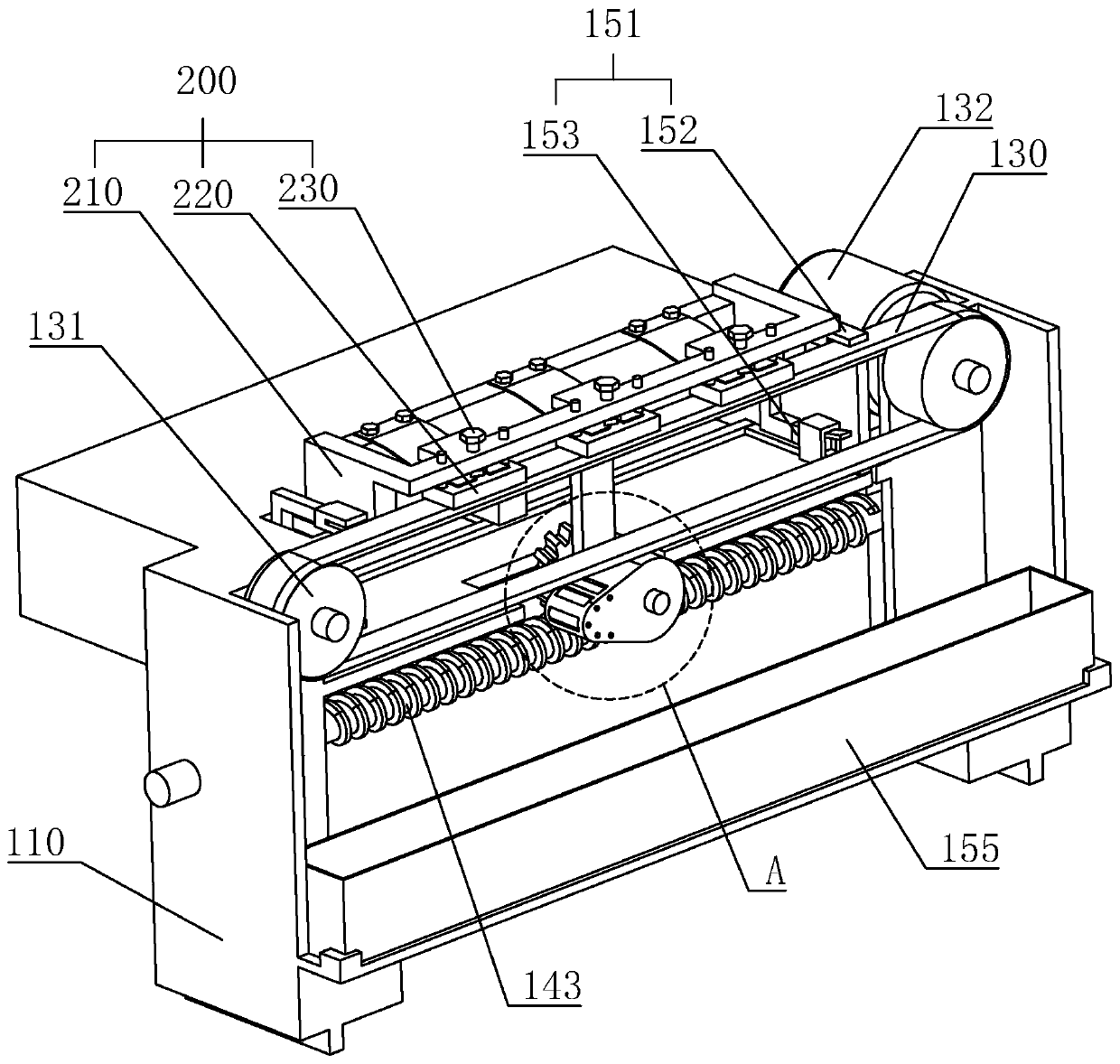

[0042] refer to figure 1 , figure 2 , the sliding frame 110 is provided with a belt knife 130, both ends of the sliding frame 110 are rotatably connected with a rotating wheel 131, the belt knife 130 is sleeved on the rotating wheel 131, and a driving motor 132 is fixed on the sliding frame 110 by bolts , the output shaft of the drive motor 132 is fixedly mounted on one of the rotating wheels 131 .

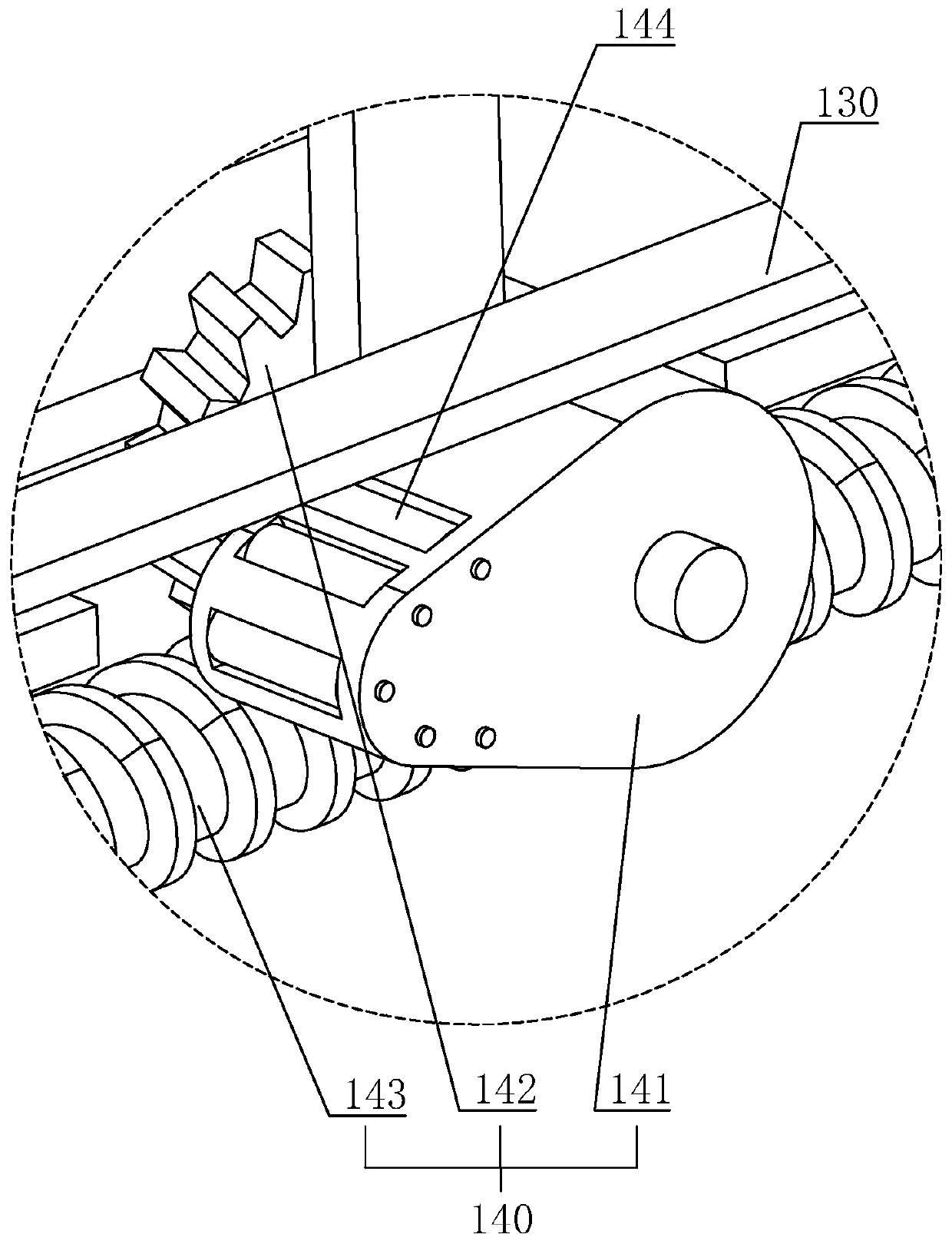

[0043] refer to figure 2 , image 3 , the sliding fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com