Fabricated double-round-shell grouting underground comprehensive pipe gallery and connecting construction method

A comprehensive pipe gallery and prefabricated technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of complex construction and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

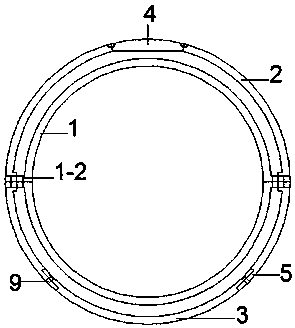

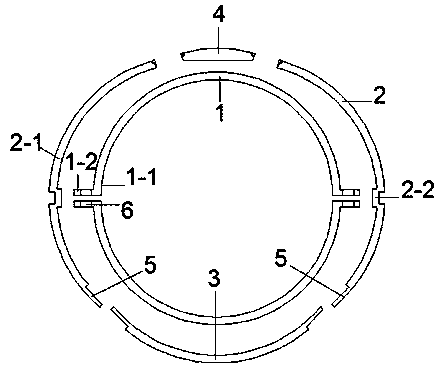

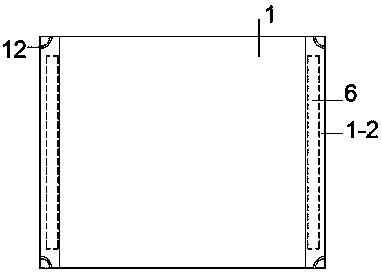

[0034] like figure 1 As shown in -7, an assembled double-circular shell grouting underground comprehensive pipe gallery includes a semicircular inner gallery body 1, a lateral outer shell body 2, an arc-shaped outer shell 2-1, a rectangular connecting rib 2-2, and a bottom outer gallery Body 3, gallery cover plate 4, rectangular rib 5, rectangular groove 6, gallery body connector 7, arc rib 8, high-strength bolt 9, reserved bolt hole 10, U-shaped bolt 11, reserved U-shaped bolt hole 12. Waterproof rubber cushion layer 13;

[0035] The semicircular inner gallery body 1 includes a semicircular arc shell 1-1, a rectangular plate 1-2, a rectangular groove 6, and reserved U-shaped bolt holes 12, and the side shape of the semicircular inner gallery body 1 is a semicircular ring , the middle part of the semicircular inner gallery body 1 is a semicircular arc shell 1-1, and a rectangular plate 1-2 is respectively arranged on the two ends of the semicircular arc shell 1-1, and a recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com