Method for preventing roadway impact ground pressure through hydraulic roof cutting and roadway leaving

A technology of rock burst and roof cutting, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of coal pillar stress concentration and aggravate the risk of rock burst, so as to reduce roadway engineering, reduce resource loss, Significant effect of social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

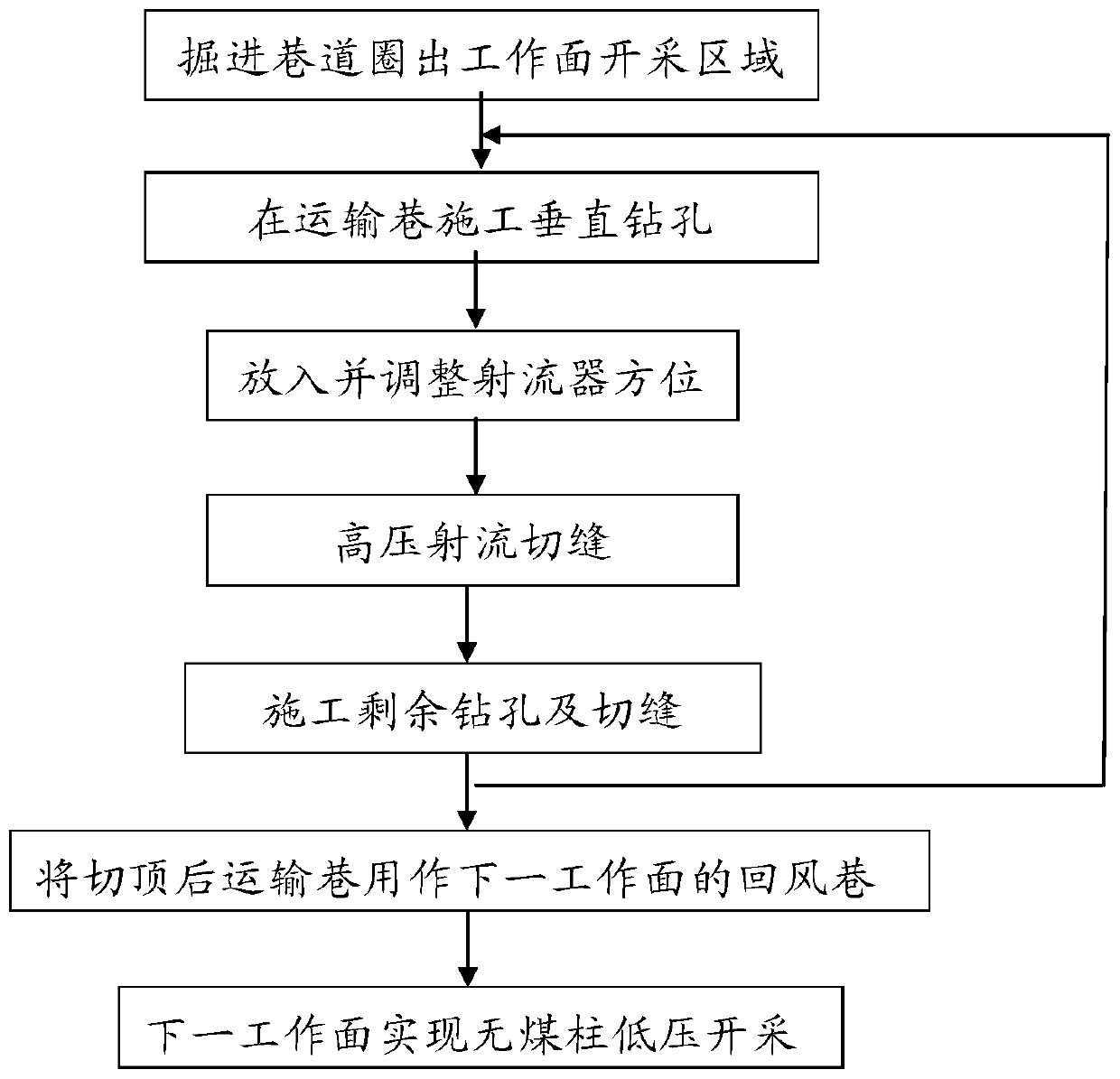

[0023] see figure 1 According to the embodiment of the present invention, a method for preventing roadway rock burst by hydraulically cutting the roof and retaining the roadway includes the following steps:

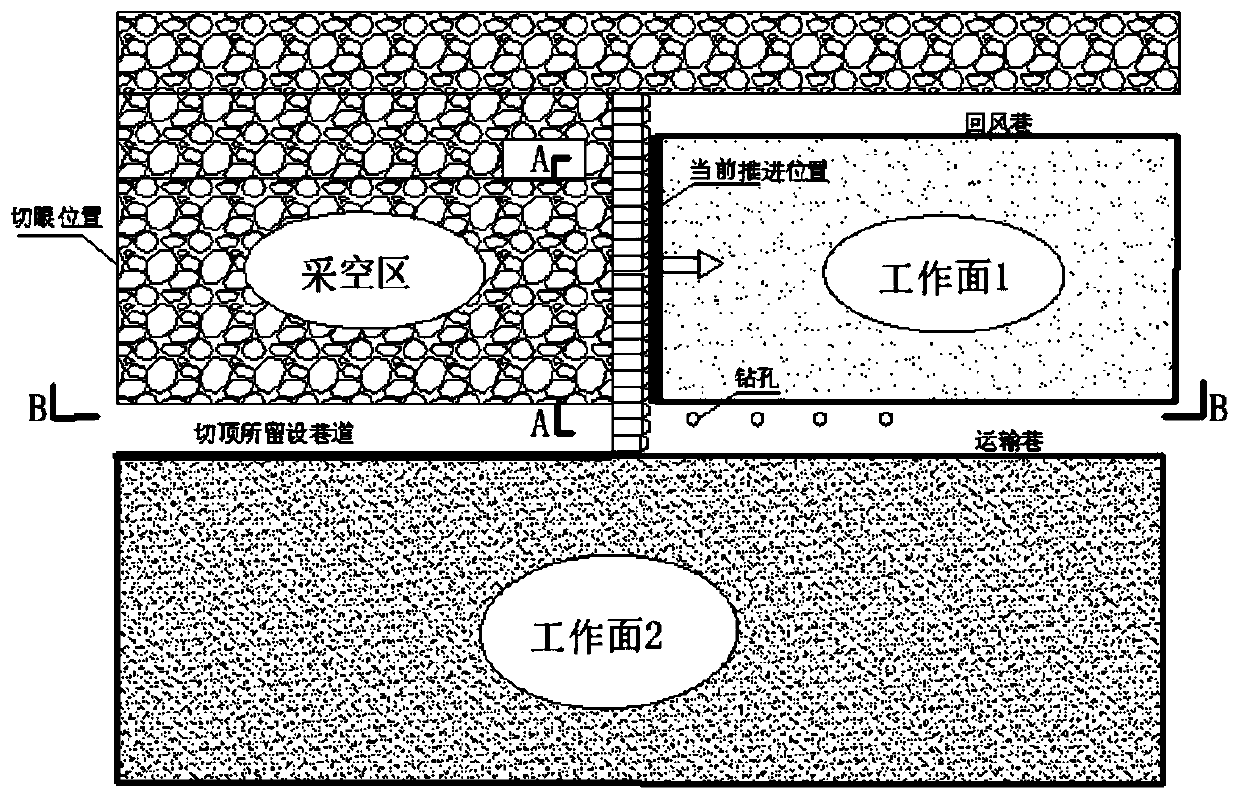

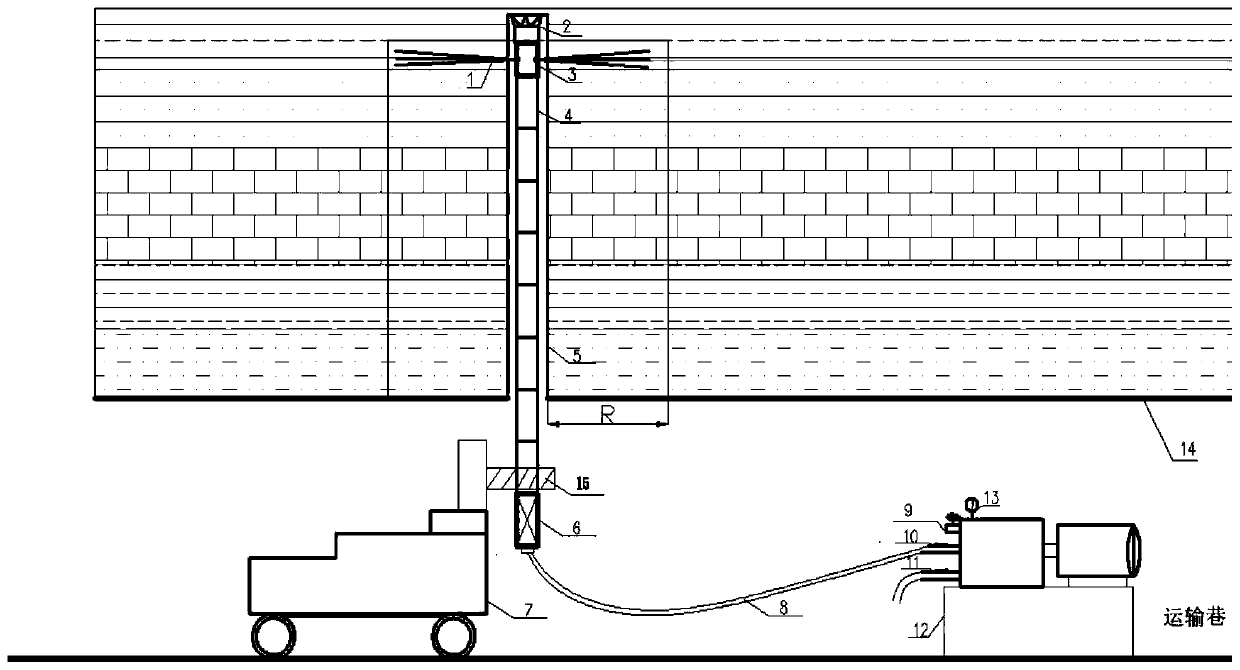

[0024] Excavate the roadway to delineate the mining area of the working face: excavate the transportation roadway, air return roadway and cutting hole respectively. During the excavation, the roof of the transportation roadway needs to be reinforced with strong anchor cables. Wherein, the working face is an area surrounded by a transport lane, an air return lane, a cutting hole and a production stop line, and this area is used for mining of coal resources. The transport lane and return air lane refer to the lanes used for transport and air return during the mining of the working face, the transport lane is the lower lane, and the return air lane is the upper lane. Wherein, the strong anchor cable is a prestressed steel strand whose outer end is fixed on the roadway sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com