Roadway intelligent gangue filling machine and filling method

A filling machine and roadway technology, applied in the direction of filling, earth cube drilling, safety devices, etc., can solve the problems of low filling efficiency, inconvenient construction of large filling tools, etc., achieve flexible and convenient installation and use of the device, ensure efficient operation, The effect of guaranteeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

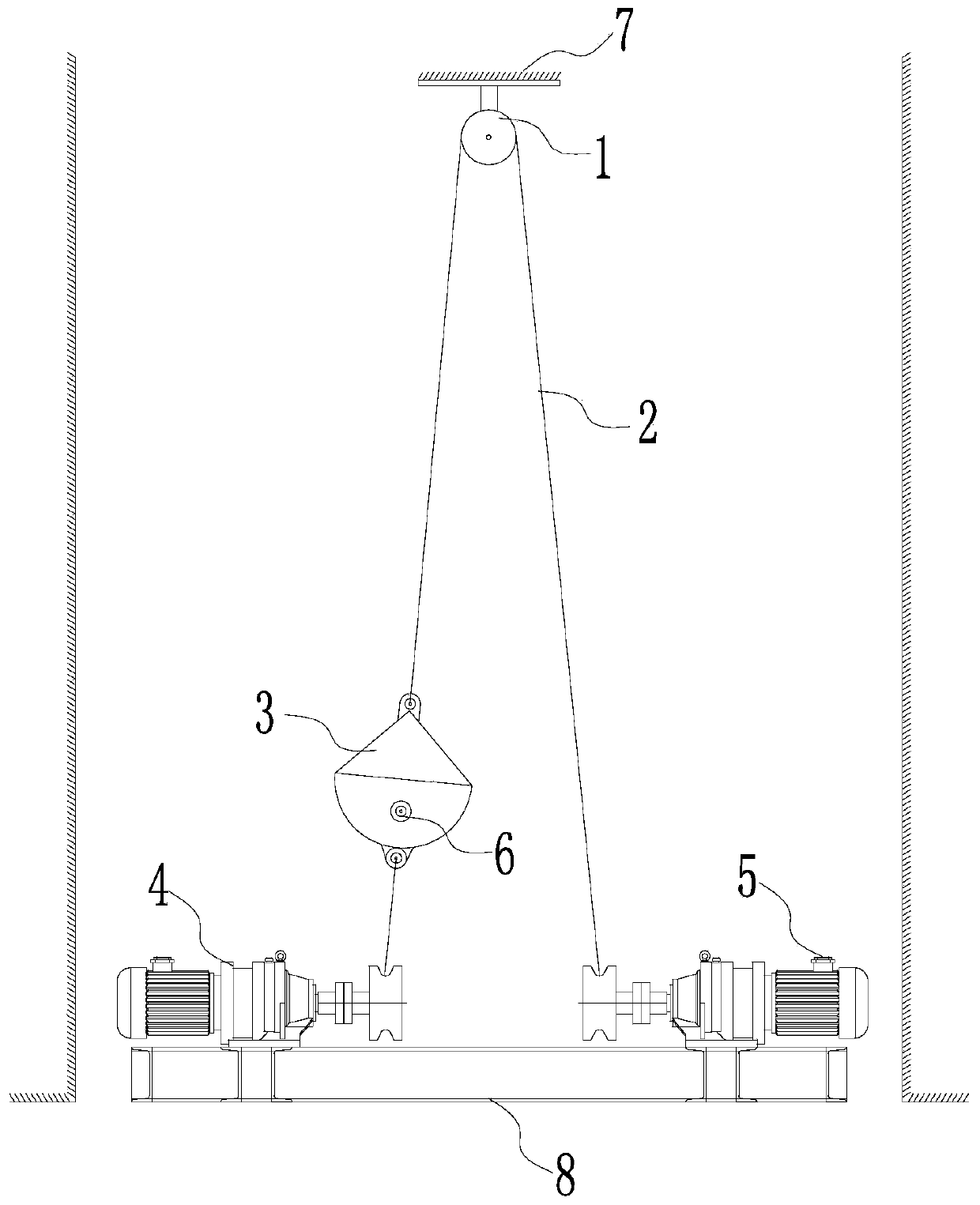

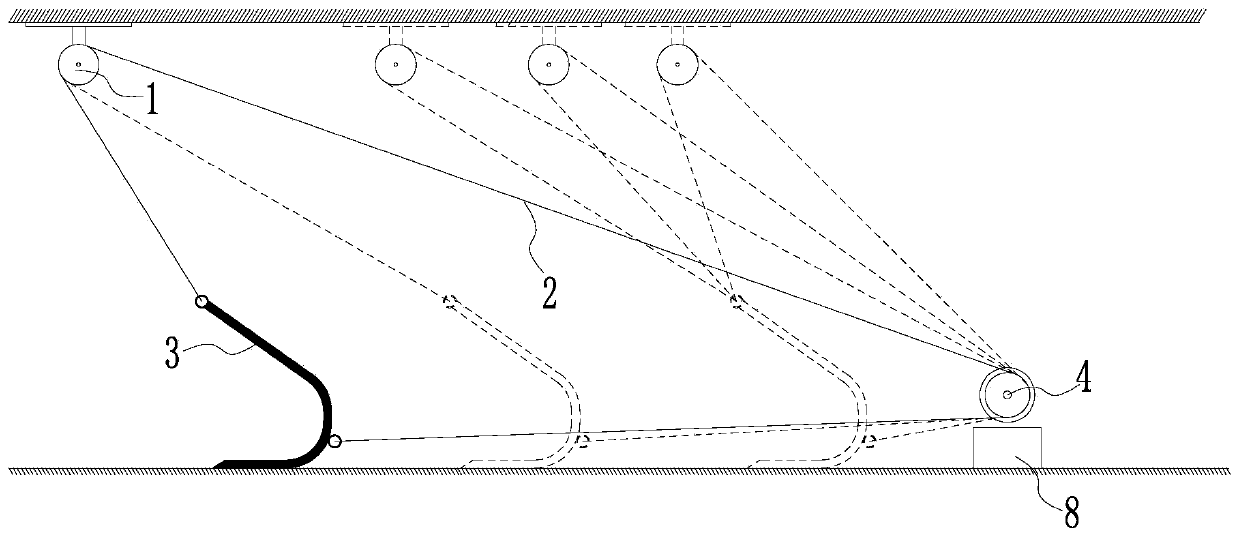

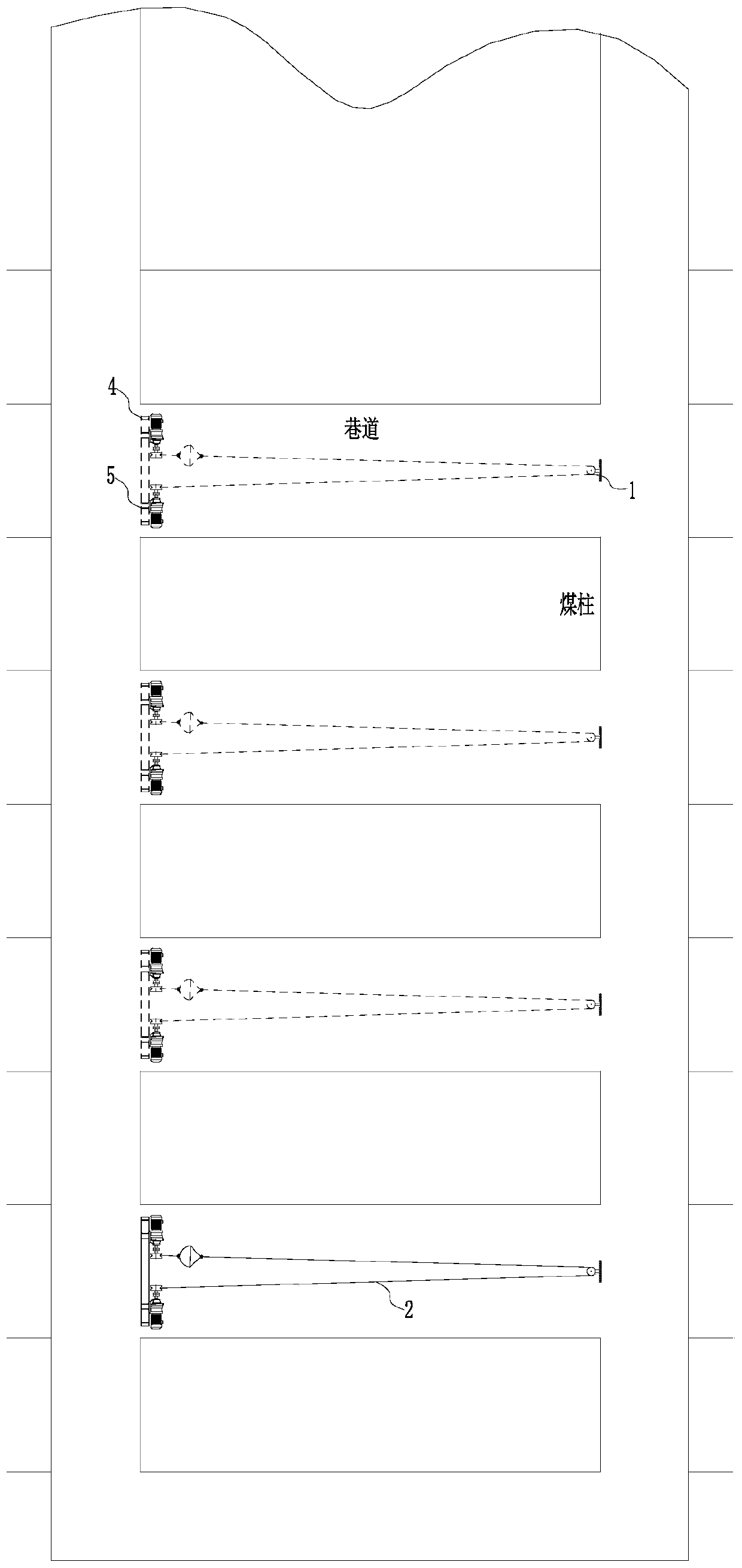

[0026] combine Figure 1 to Figure 4 As shown, the specific implementation of a roadway intelligent gangue filling machine and filling method provided by the present invention is as follows.

[0027] A roadway intelligent gangue filling machine specifically includes a pulley roof fixing device 1, a traction rope 2, a filling bucket 3, a first electric drum 4, a second electric drum 5, a position sensor 6 and a controller. The roof fixing device 1 is used as the rotary connection mechanism of the traction rope 2, the traction rope 2 pulls the filling bucket 3 to reciprocate, the first electric drum 4 and the second electric drum 5 realize the traction of the movement direction of the traction rope 2, the position sensor and the controller In combination, the danger caused by the overwinding of the electric drum can be prevented by controlling the operation of the first electric drum 4 and the second electric drum 5 .

[0028] Wherein, the pulley top plate fixing device 1 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com