Denoising method for fault vibration signal of aeroengine rotor system

An aero-engine and vibration signal technology, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc., can solve the problems that the noise background spectrum cannot be effectively filtered out and affect the reasonable extraction of rotor fault features, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

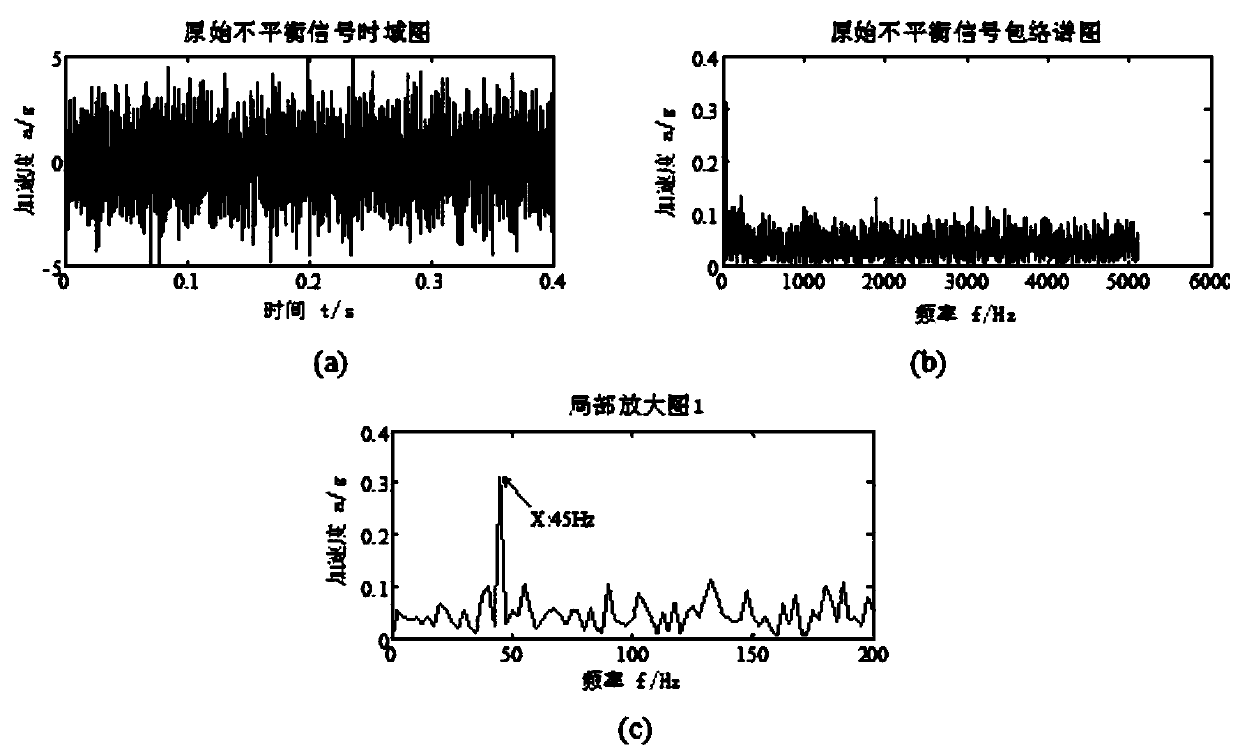

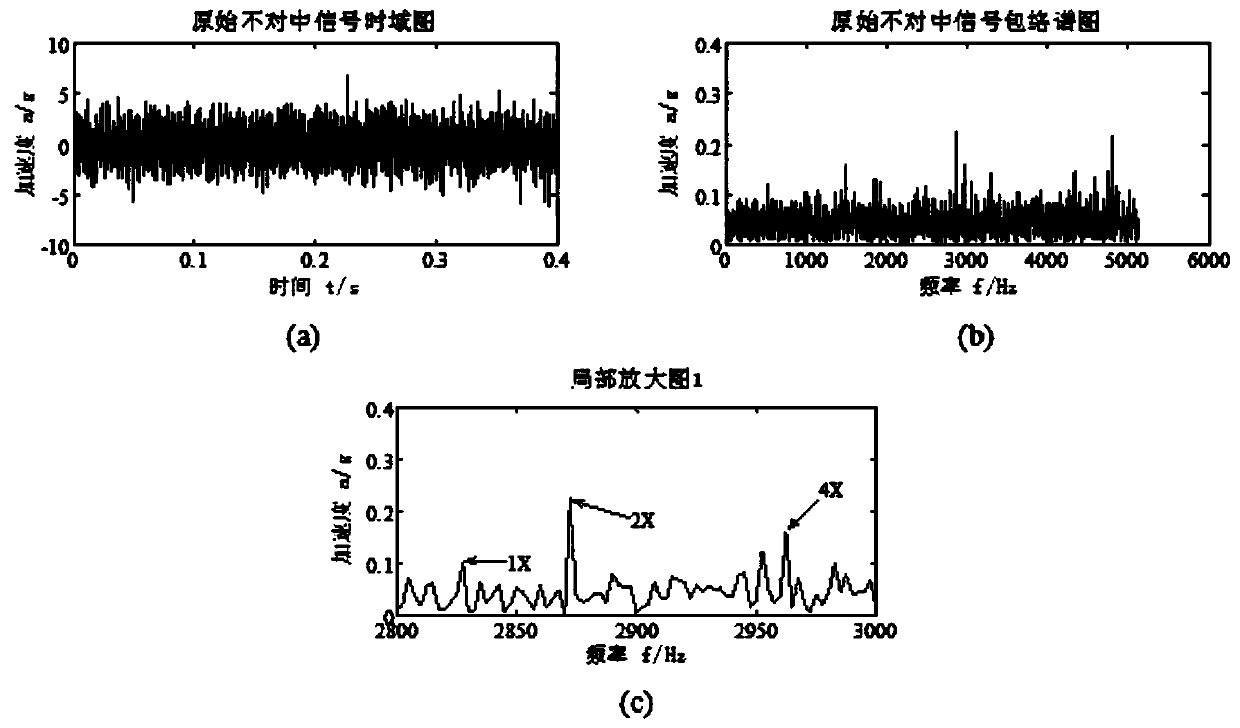

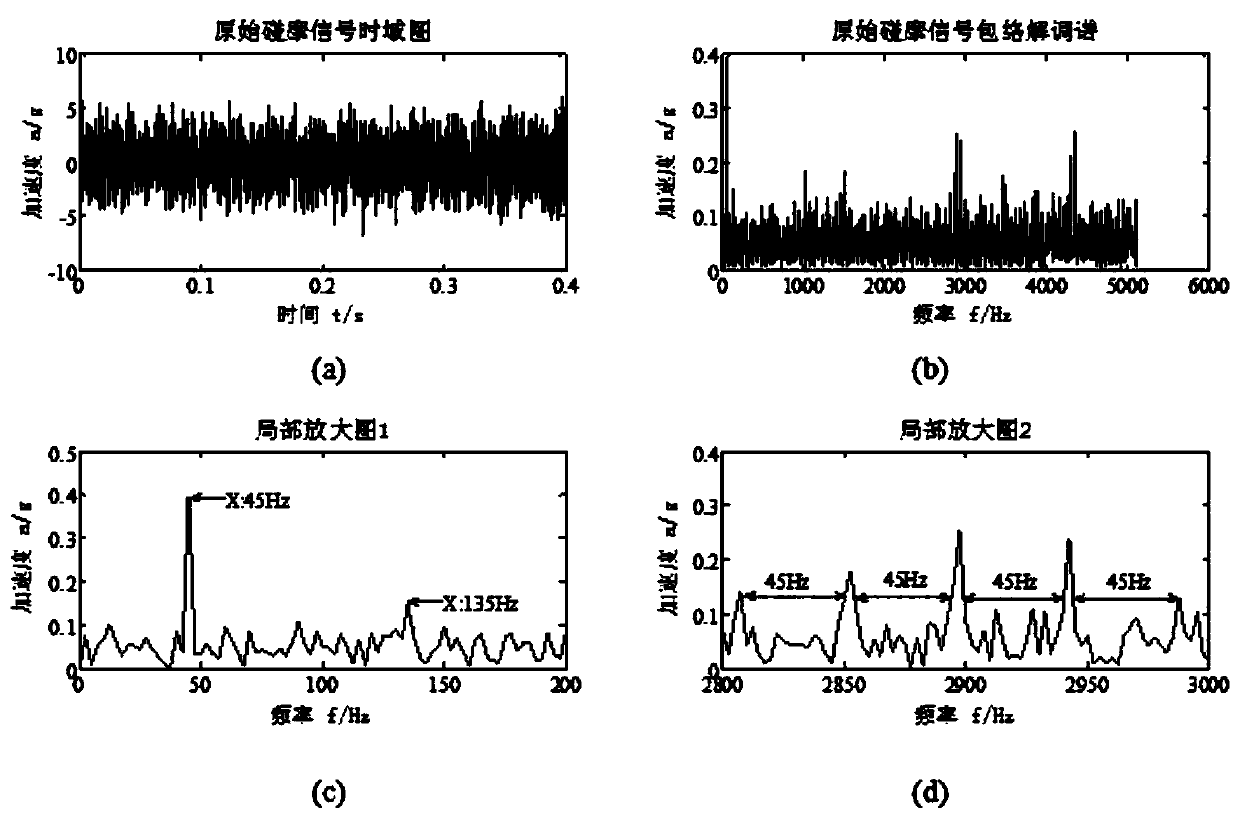

Image

Examples

Embodiment Construction

[0050] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the specific embodiments of the present invention are clearly and completely described below to further illustrate the present invention. Obviously, the described specific implementation The form is only a part of embodiment of this invention, and it is not all form.

[0051] Aero-engine is a key component of aircraft, known as a "pearl" in the aviation industry. At present, all major aviation countries have listed aero-engine maintenance technology as one of the most secrets that need to be kept. Due to the precision and complexity of its parts and components, aero-engines have a high probability of failure, and the types of failures are also varied. The specific types of failures can be seen in the following table 1. Common failure types and characteristic frequencies of aero-engines. Relevant research statistics sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com