Panel edge sealing defect detection device and application method

A defect detection and sheet metal technology, applied in measurement devices, optical testing of flaws/defects, analysis of materials, etc., can solve the problems of lack of detection measures, prone to missed inspections, low efficiency, etc., to reduce missed inspections and set reasonable settings. , the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

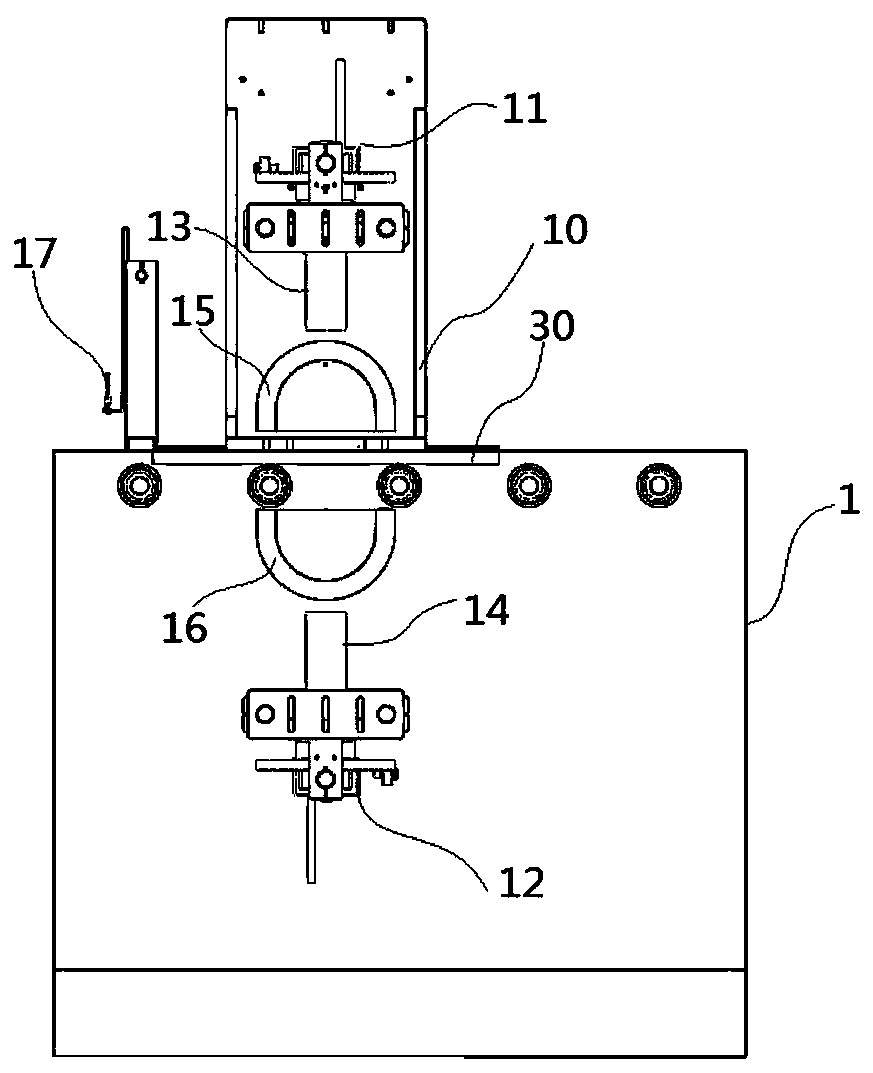

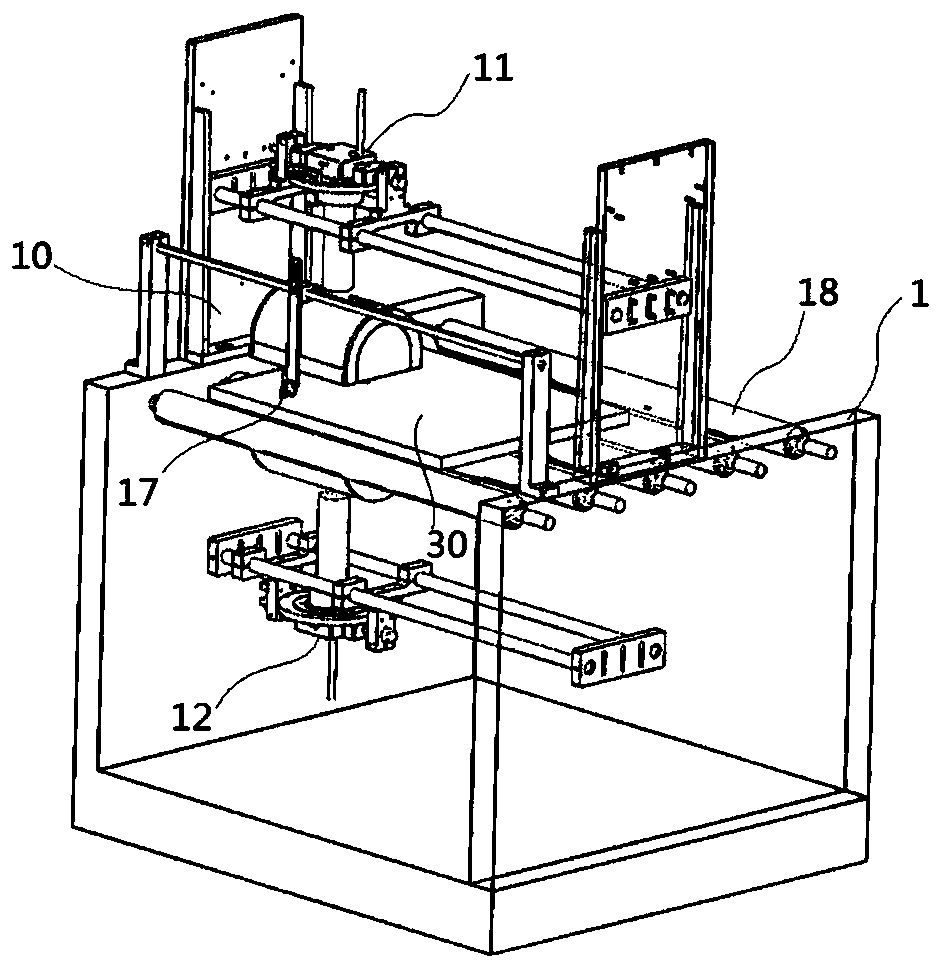

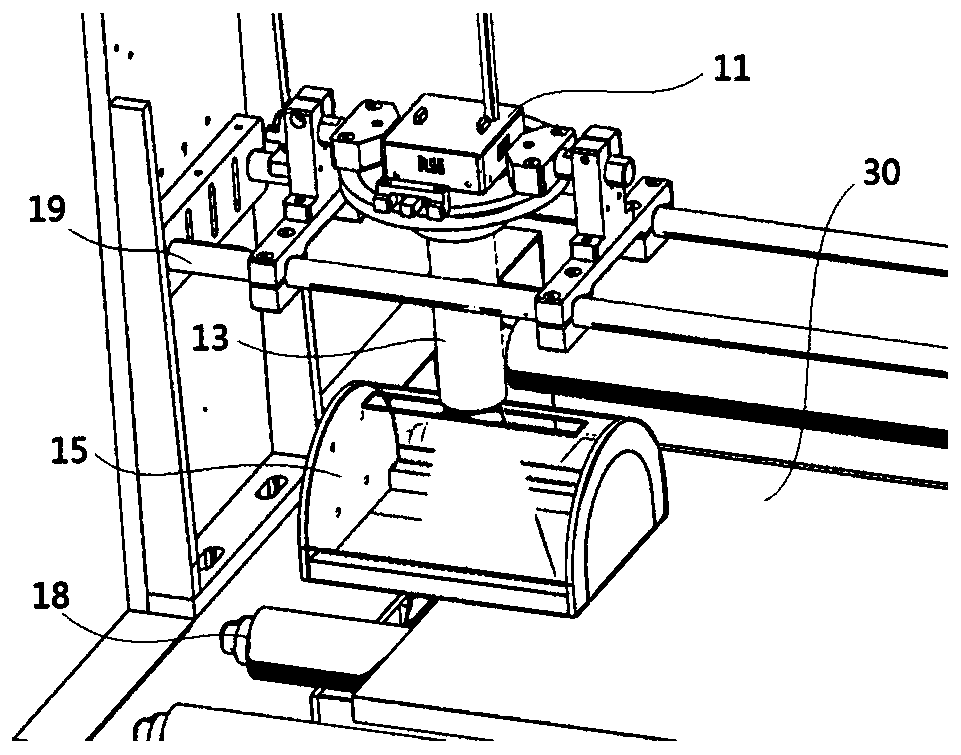

[0045] like Figure 1-5 The device for detecting edge-sealing defects of sheet metal according to the present invention includes, but is not limited to: a frame 1, a position switch 17, a scanning detection module, a lighting module, and a computer.

[0046] according to Figure 4 , Figure 5 As shown, the board 30 has a board body 20 (for the surface of the board), a sealing tape 21 , and a glue coating 22 , and occasionally a part of it will be chipped 23 .

[0047] The frame 1 is provided with a detection station 10 for providing an installation basis; the in-position switch 17 is arranged on the side of the detection station 10, specifically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com