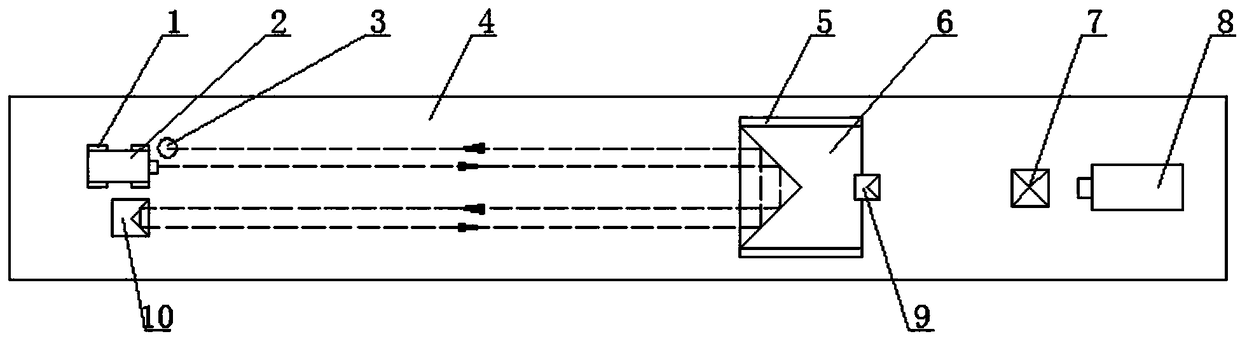

Laser rangefinder verification device based on principle of error cancellation and verification method thereof

A laser rangefinder and laser interferometer technology, applied in radio wave measurement systems, instruments, etc., can solve the problems of poor measurement stability, difficult operation, difficult beam position constraints, etc., to improve the multiplier efficiency and high measurement accuracy. , the effect of good measurement stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail through the following examples, which are illustrative rather than restrictive, and cannot limit the protection scope of the present invention.

[0034] 1. Research methods:

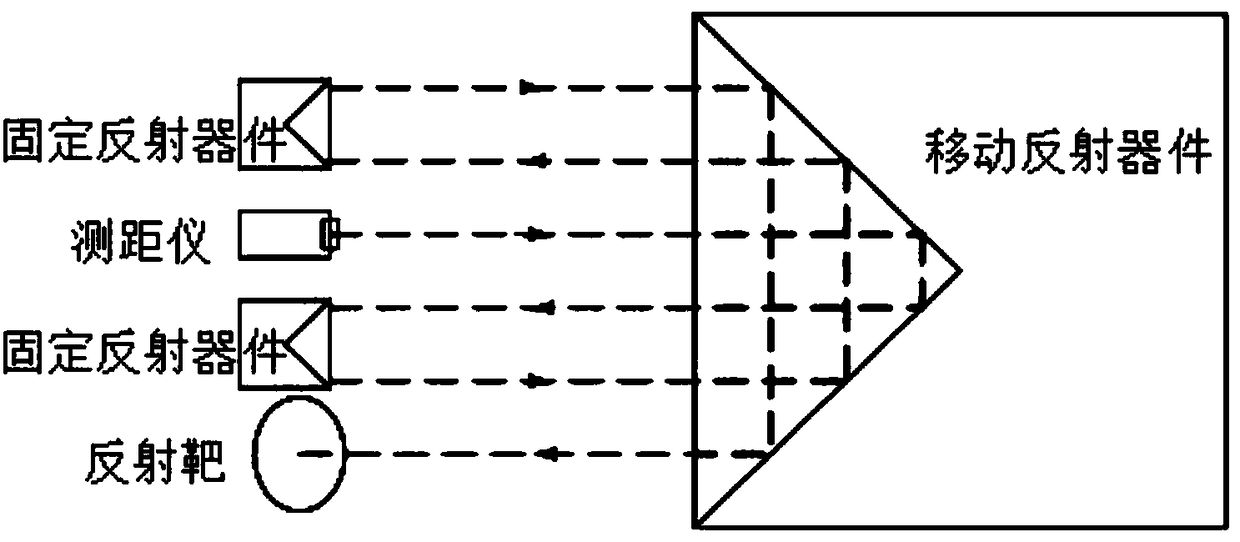

[0035] (1) Optical path calibration and error cancellation method

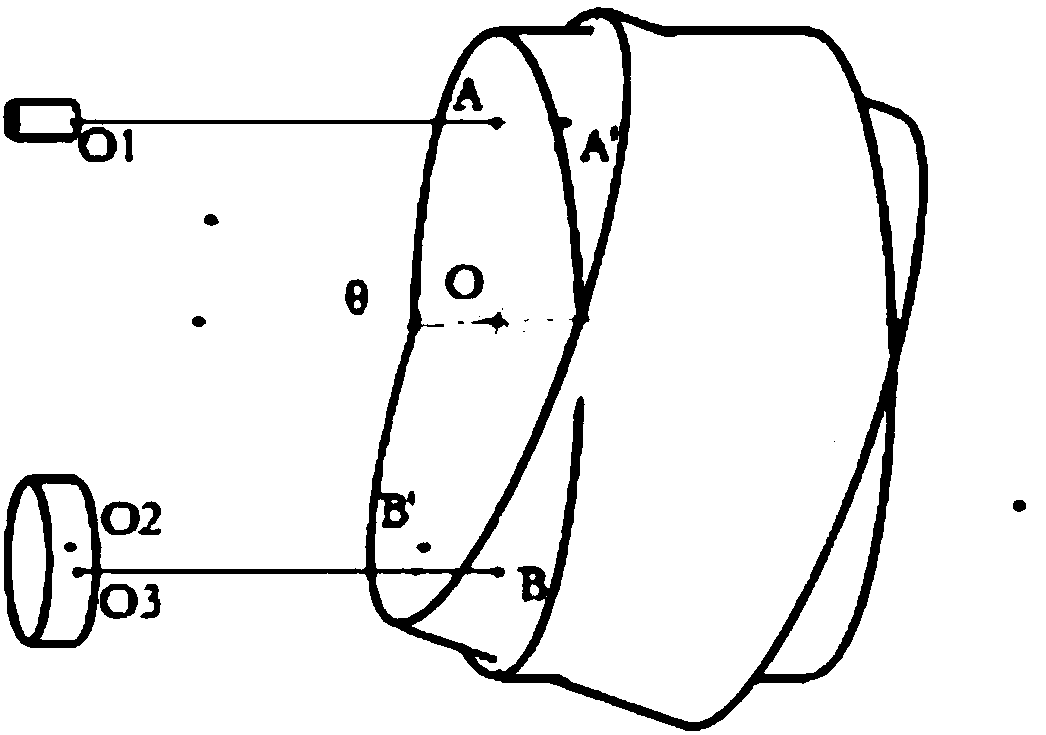

[0036] like figure 2 As shown, in the ideal posture, the laser rangefinder emits a laser beam at O1 and hits point A of the mobile reflective device, and the beam is reflected from point B to point O3 of the fixed reflective device in parallel after reflection. The light beam and the optical axis of the reflective device are deflected by an angle of θ, causing the light beam to be incident on point A' and reflected from point B' to point O2. Suppose the optical path from O1 to A is a, the optical path from O1 to A' is a', the optical path from O2 to B' is b', and the optical path from O3 to B is b. Symmetry, no matter how the azimuth angle θ changes: a+b=a'+b', the measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com