A method for driving flexible photonic crystals to change color based on shape memory alloy polymers

A memory alloy and photonic crystal technology, applied in optics, optical components, instruments, etc., can solve the problems of high driving voltage and insufficient flexibility of the overall structure of photonic crystal discoloration, so as to ensure stretchability, achieve precise control and stable display. , the effect of good discoloration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] S2. Preparation of flexible photonic crystals;

[0045] S201, processing a cylindrical array on a silicon wafer by ion beam processing, wherein the cylindrical diameter is 200-600 nm, the depth is 200-600 nm, the hole spacing is 400-1200 nm, and the arrangement is triangular;

[0046] S202: Pour the Dow Corning 184 silicone rubber on the surface of the processed silicon wafer and heat it at 40-80°C for 2-6 hours to cure to prepare a flexible photonic crystal.

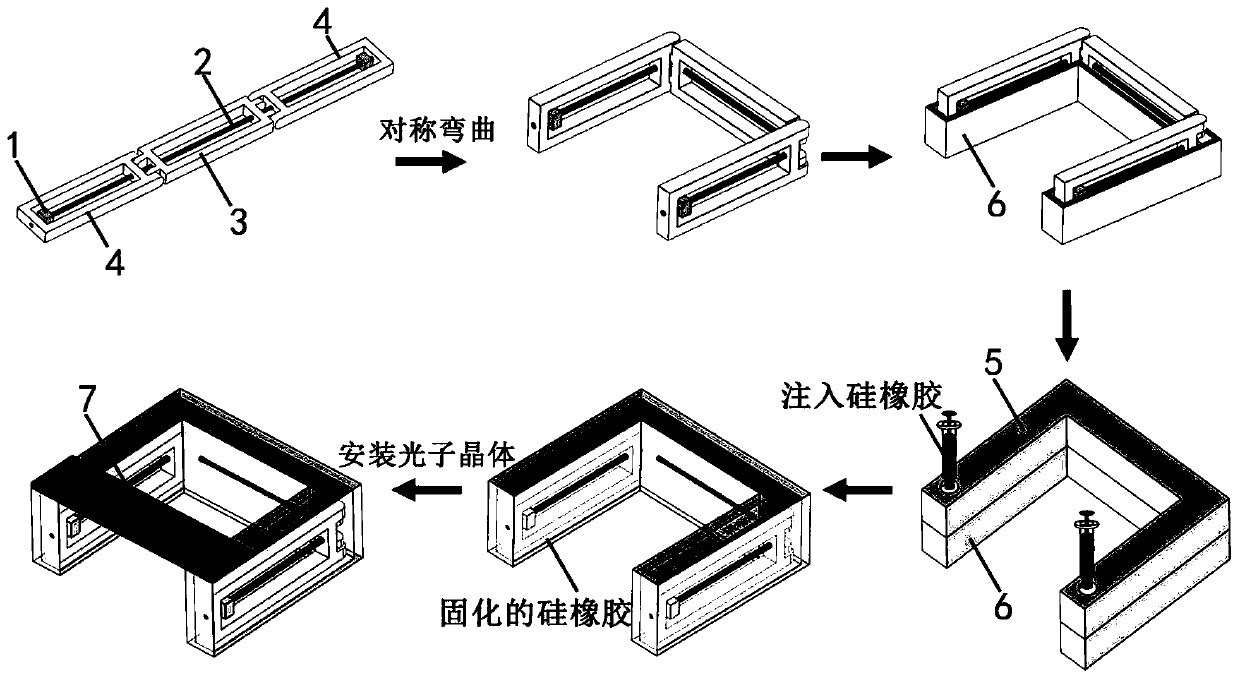

[0047] S3. Preparation of overall discoloration structure;

[0048] The flexible photonic crystal is connected with the U-shaped driver based on shape memory alloy polymer through the Smooth-on silicone rubber adhesive.

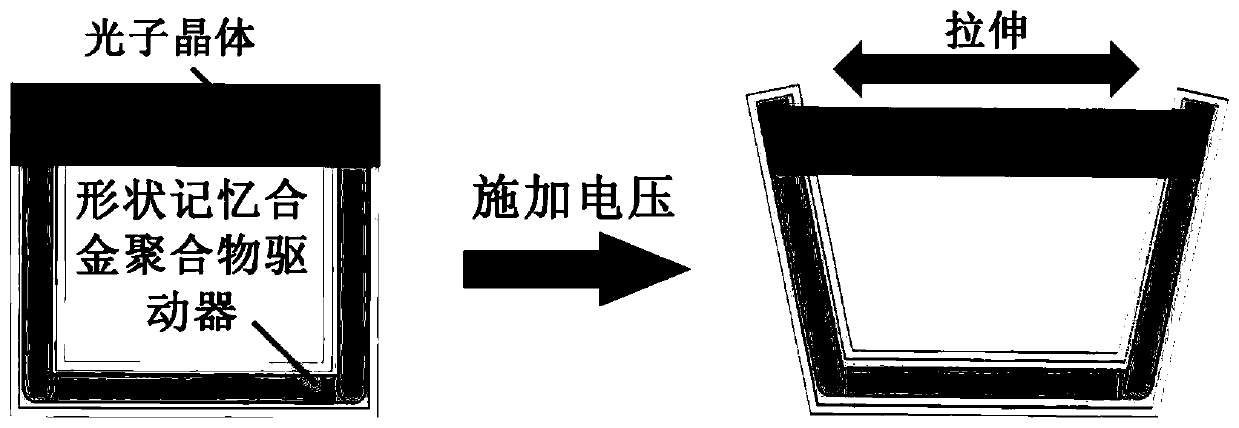

[0049] S4. Discoloration process;

[0050] S401. First, fix the bottom of the U-shaped driver stably and adjust the intensity and position of the light source to make the surface of the photonic crystal appear red;

[0051] Among them, the light source is a 5-40W white light source, and the incident angle i...

Embodiment 1

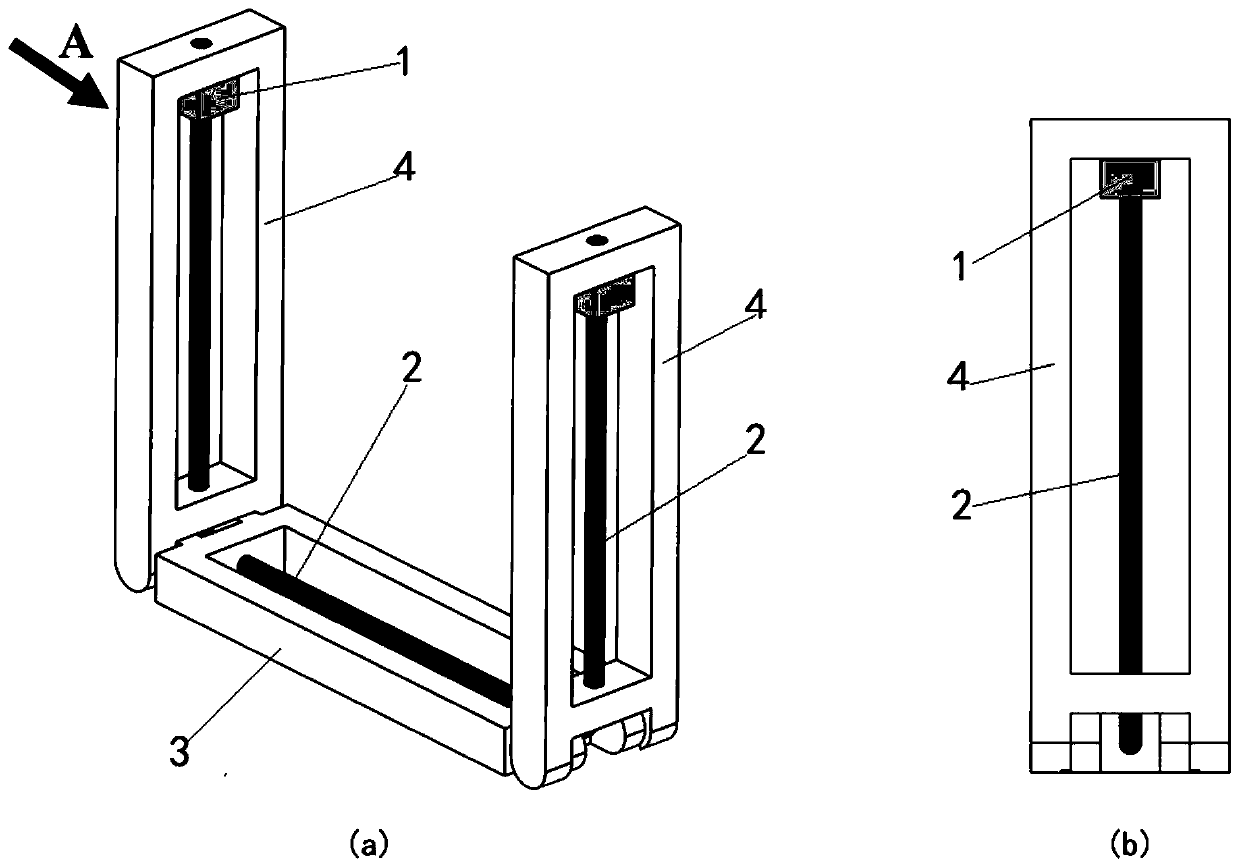

[0060] 1) Preparation of the drive;

[0061] A shape memory alloy wire with a diameter of 1 mm is inserted into the designed rigid structure to form a U-shaped drive structure. Furthermore, the Ecoflex-0050 silicone rubber is poured on its surface and cured by heating at 40°C for 3 hours to form a U-shaped actuator based on a shape memory alloy polymer;

[0062] 2) Preparation of flexible photonic crystals;

[0063] The cylindrical array is processed on the silicon wafer by ion beam processing, the diameter of the cylinder is 400nm, the depth is 400nm, the hole spacing is 800nm, and the arrangement is triangular; the surface of the processed silicon wafer is poured with Dow Corning 184 silicone rubber and heated at 60℃4 Cured within hours to prepare flexible photonic crystals;

[0064] 3) Preparation of overall discoloration structure;

[0065] Connect the flexible photonic crystal with the U-shaped driver based on shape memory alloy polymer through Smooth-on silicone rubber adhesive;...

Embodiment 2

[0071] 1) Preparation of the drive;

[0072] A shape memory alloy wire with a diameter of 0.4mm is inserted into the designed rigid structure to form a U-shaped drive structure. Furthermore, the Ecoflex-0050 silicone rubber is poured on its surface and cured by heating at 20°C for 6 hours to form a U-shaped actuator based on a shape memory alloy polymer;

[0073] 2) Preparation of flexible photonic crystals;

[0074] The cylindrical array is processed on the silicon wafer by ion beam processing, the diameter of the cylinder is 200nm, the depth is 200nm, the hole spacing is 400nm, and the arrangement is triangular; the surface of the processed silicon wafer is poured with Dow Corning 184 silicone rubber and heated at 40℃6 Cured within hours to prepare flexible photonic crystals;

[0075] 3) Preparation of overall discoloration structure;

[0076] Connect the flexible photonic crystal with the U-shaped driver based on shape memory alloy polymer through Smooth-on silicone rubber adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com