Battery cell fusing bar

A cell and fusing technology, applied in the direction of batteries, circuits, electrical components, etc., can solve the problems of short circuit of cells, increasing the complexity of battery structure, and endangering personal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

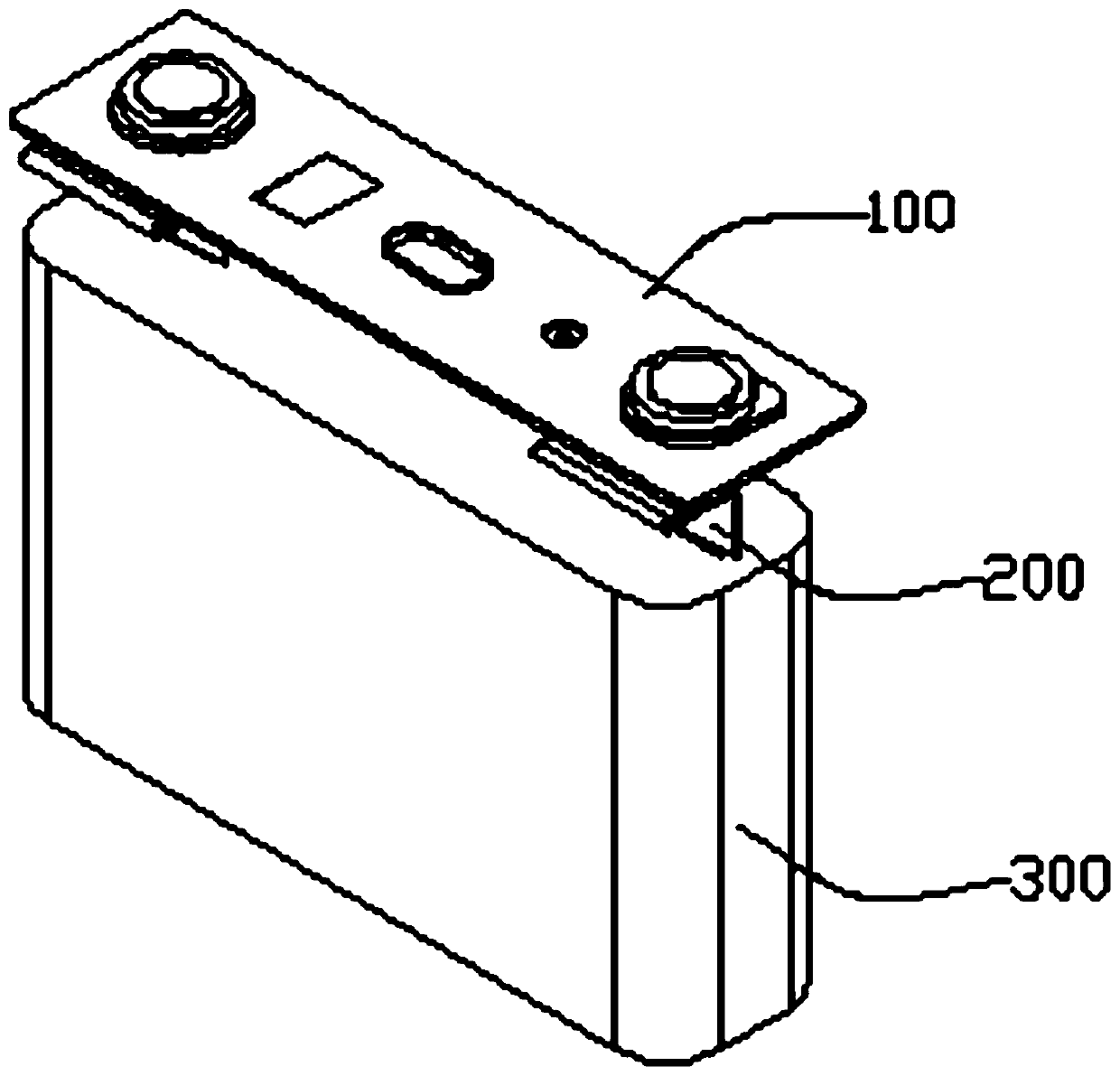

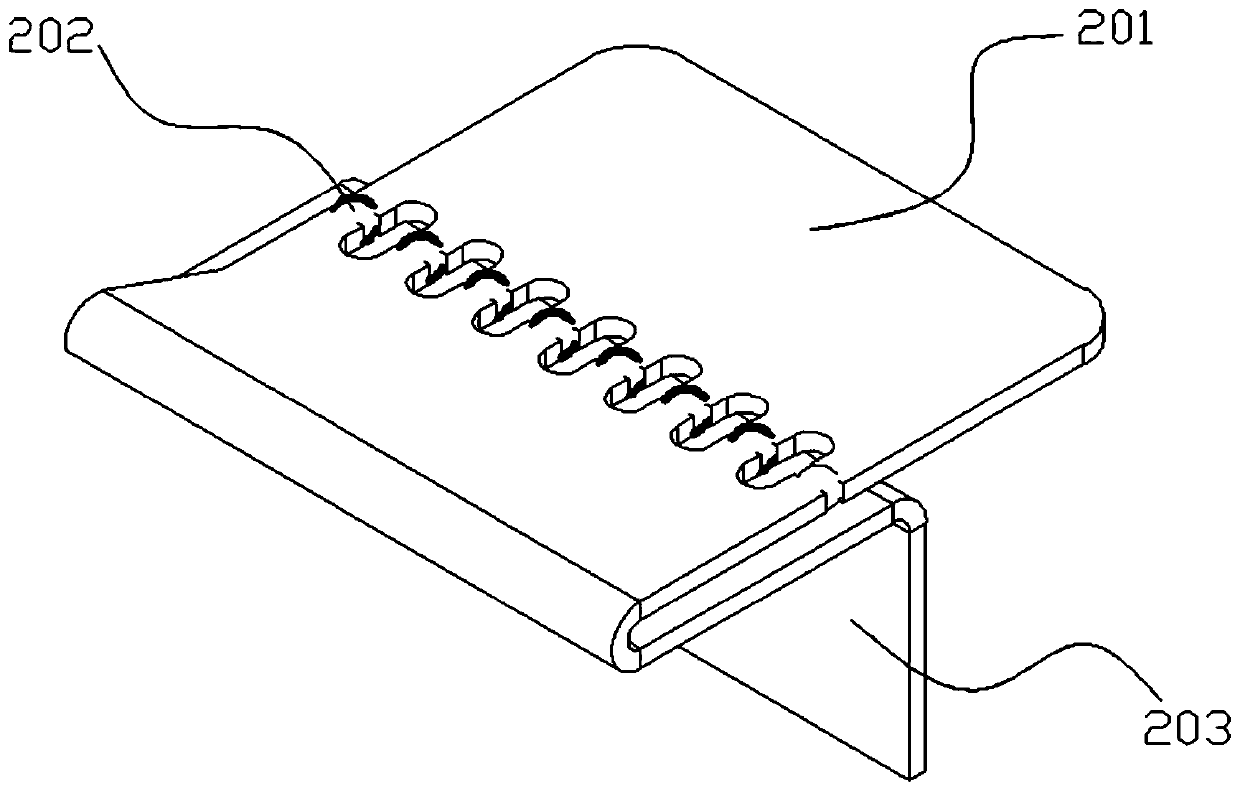

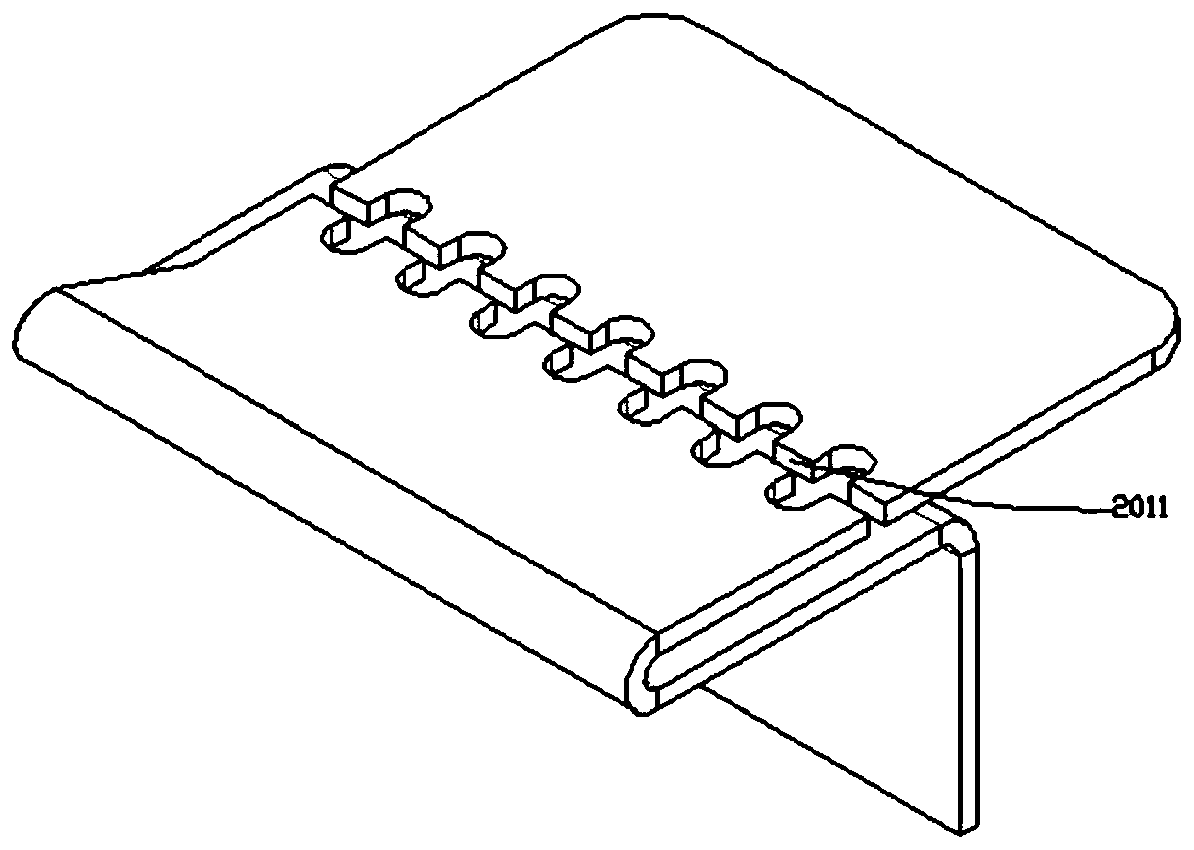

[0023] see Figure 1-Figure 3 , a cell fuse bar provided by the present invention includes a connecting bar 200, the connecting bar 200 has a connecting groove 2011, and the connecting groove divides the connecting bar into two parts, called the first part 201 and the second part. Part 203, the first part 201 is used to connect the cell top cover 100, one end of the second part 203 is used to connect the cell body 300, and the connecting groove 2011 includes a set of arc-shaped grooves, which are used to closely contact and connect a set of melting beads 202 , the shape of the melting bead matches the arc groove, the melting bead 202 and the connection bar 200 are both conductors, and the melting point of the melting bead 202 is lower than the melting point of the connecting bar 200 .

[0024] In the electric core fusing bar provided by the present invention, when the current is overloaded or short-circuited, when the current flows through the melting bead, the melting point o...

Embodiment 2

[0026] On the basis of the embodiment, the first part is connected to the cell top cover by laminated polymer diffusion welding to form a soft connection, and one end of the second part is connected to the cell body by laminated polymer diffusion welding to form a soft connection . Polymer diffusion welding can ensure the stability of the connection row size and material.

Embodiment 3

[0028] On the basis of embodiment 2, the material of the connecting bar may be copper or aluminum, and the material of the melting bead is a material with high conductivity, specifically one of silver, copper, aluminum and the like. For example, when the material of the connecting row is copper, the material of the melting bead is aluminum or silver; when the material of the connecting row is aluminum, the material of the melting bead is silver.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com