Suspension pneumatic lifting device and suspension pneumatic lifting method

A lifting device and hoisting technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem that the pneumatic balancer cannot realize the full suspension lifting of heavy objects of different weights, reduce the availability of production capacity, and reduce the suspension lifting capacity of the pneumatic balancer. Heavy range and other issues to achieve the effect of improving assembly accuracy and production efficiency, reducing response time, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

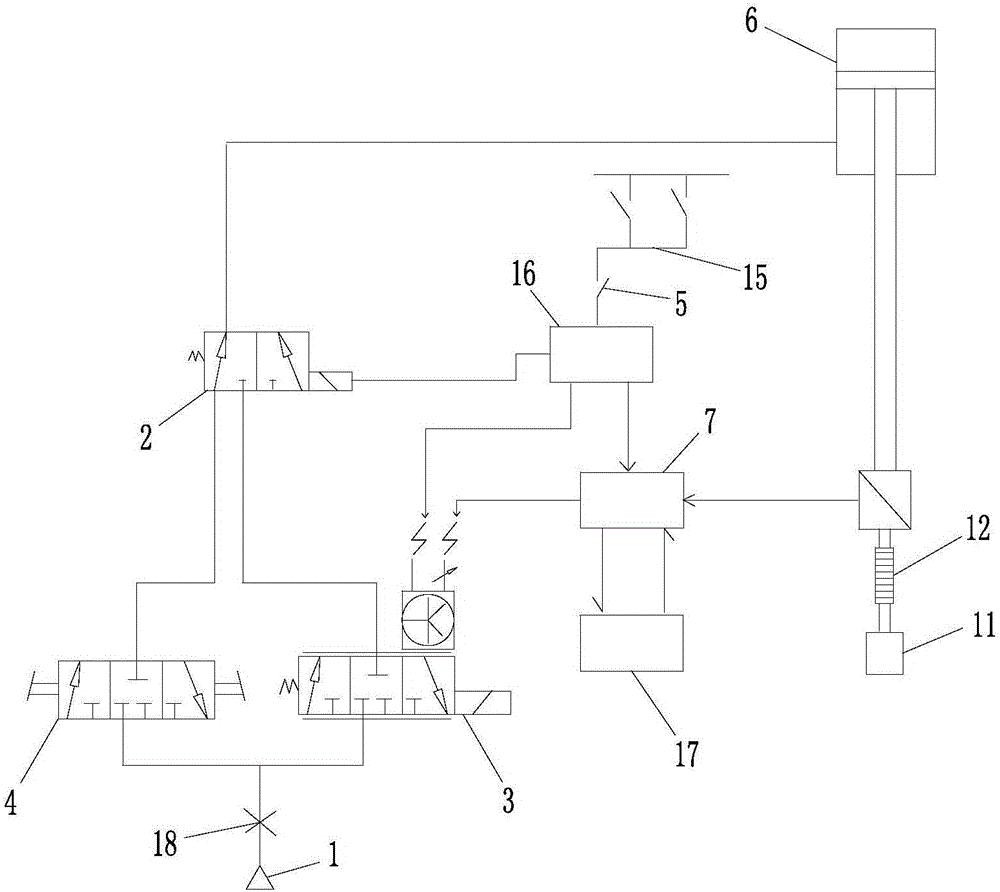

[0049] A suspended pneumatic lifting device, including an air source 1, a power supply connection circuit, a reversing valve 2, an electrical proportional valve 3, a two-position three-way solenoid valve 4, a normally-off switch 5, a pneumatic lifting device 6, a controller 7, a single The directional valve 18 and the tension sensor, the directional valve and the electric proportional valve are respectively connected with the air source and the two-position three-way solenoid valve, the two-position three-way solenoid valve is connected with the pneumatic lifting device, and the power access circuit has a function for controlling the electric proportional Valve, two-position three-way solenoid valve and normally-off switch for power supply of the controller, and the one-way valve is set on the output port of the air source;

[0050] The tension sensor is set on the execution end of the pneumatic lifting device to measure the weight of the lifting object;

[0051] The tension s...

Embodiment 2

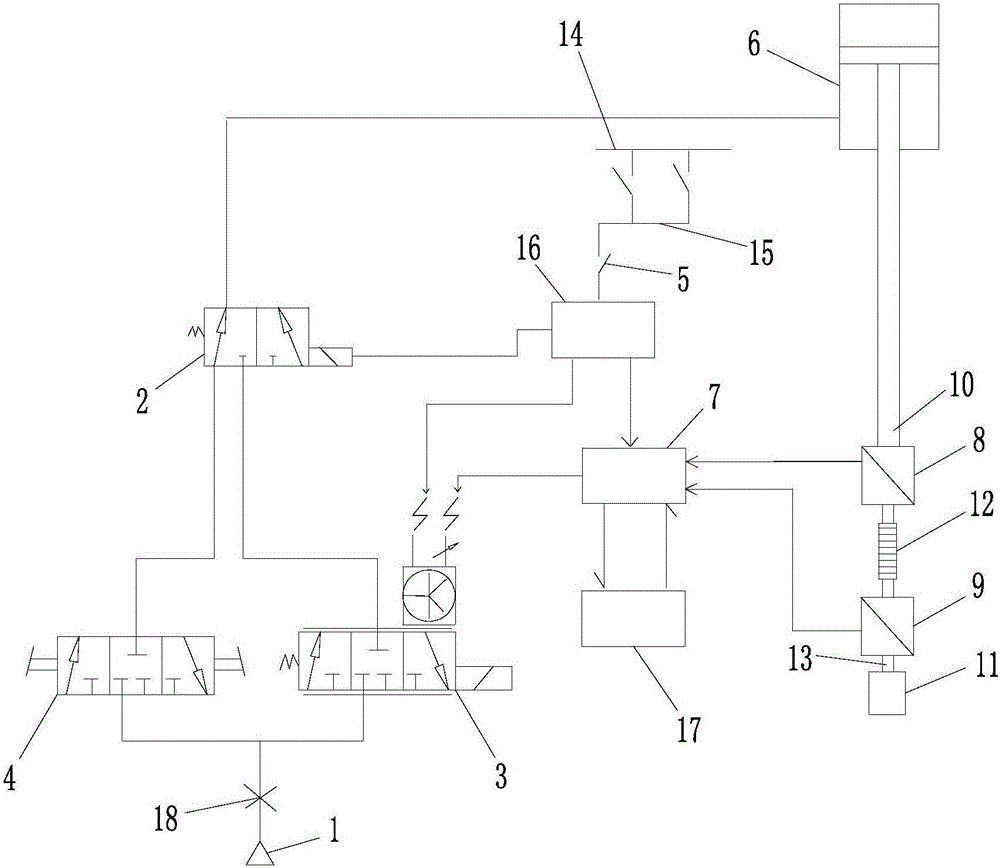

[0057] The difference between this embodiment and Embodiment 1 is that the tension sensor includes a first tension sensor 8 and a second tension sensor 9, the first tension sensor is connected to the execution end 10 of the pneumatic lifting device, and the second tension sensor is connected to the second tension sensor. a tension sensor below;

[0058] The first tension sensor and the second tension sensor are respectively connected to the controller, and the first tension sensor is used to measure the total weight of the object connected thereunder;

[0059] The second tension sensor is used to measure the weight of the hoisting object 11;

[0060] The controller is used to receive the detection data of the first tension sensor and the second tension sensor, and compare the two detection data values, if the difference between the two detection data values is less than the set value, control the electric proportional valve The one-position three-way solenoid valve is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com