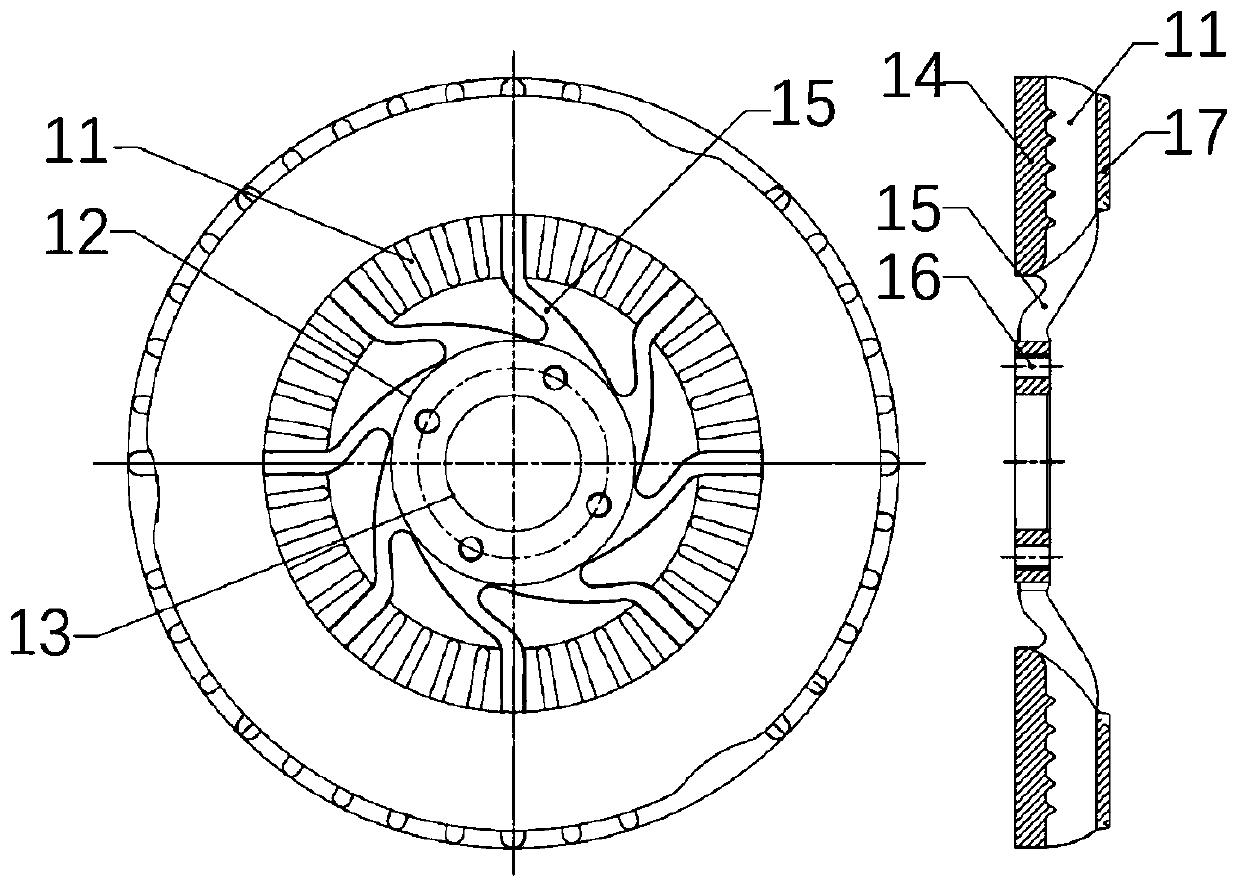

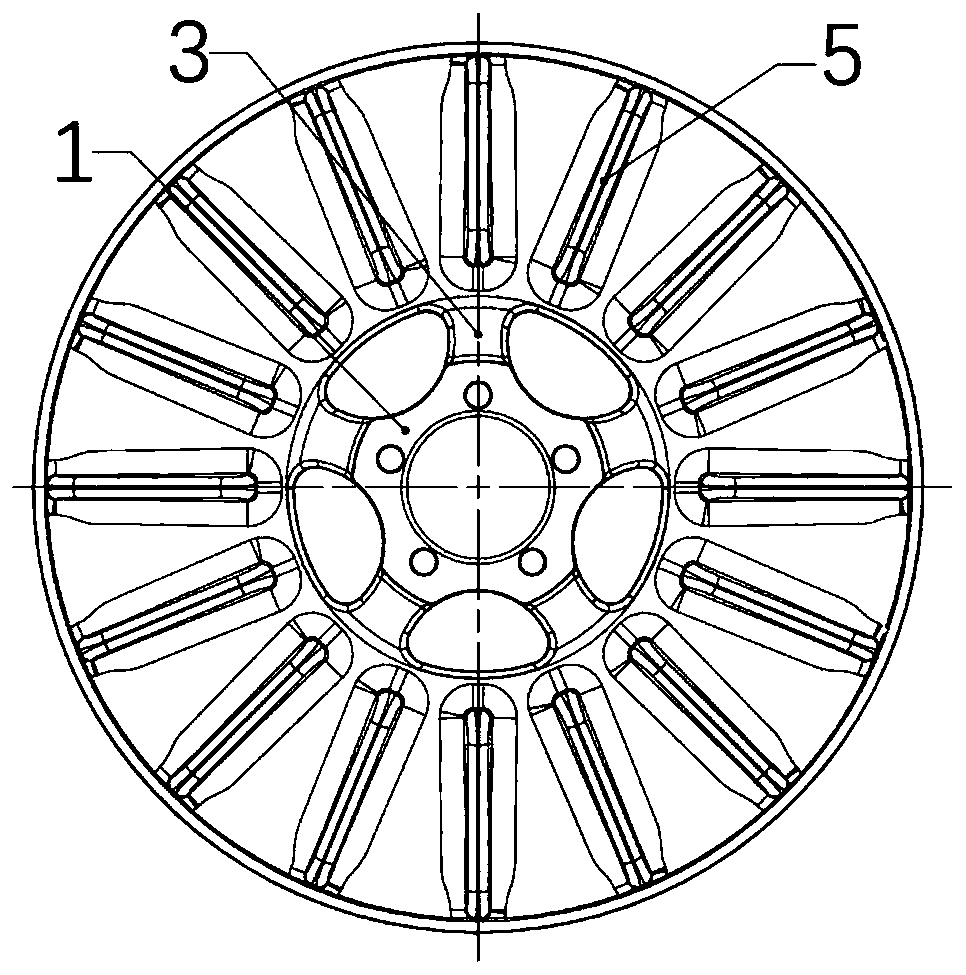

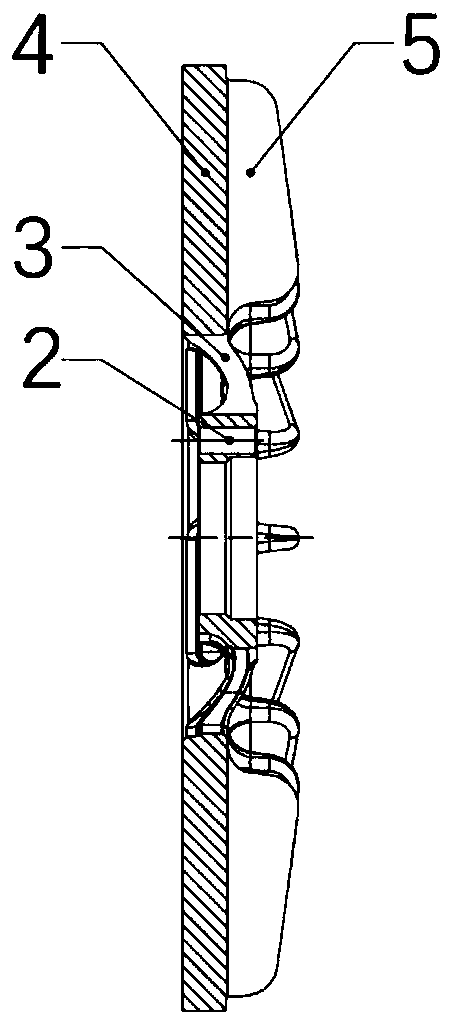

Novel eddy current retarder rotor

An eddy current retarder and rotor technology, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of complex production and casting of double-layer structures, high manufacturing and maintenance costs, and reduced rotor structural strength. Small deformation, small wind resistance and good heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention should be understood as not limited to such embodiments described below, and the technical idea of the present invention can be implemented in combination with other known technologies or other technologies having the same functions as those known technologies.

[0029] In the description of the following specific embodiments, in order to clearly demonstrate the structure and working mode of the present invention, many directional words will be used to describe, but "front", "rear", "left", "right", "outer Words such as ", "inwardly", "outwardly", "inwardly", "axially" and "radially" are to be understood as convenient terms and should not be understood as limiting terms.

[0030] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com