a photocatalyst la 2 (wo 4 ) 3 and its application

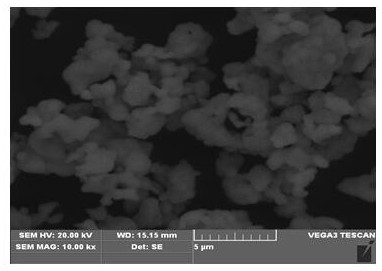

A photocatalyst and reaction technology, applied in photocatalyst La23 and its application field, can solve the problems of low photocatalytic efficiency and small photoresponse range of photocatalyst, and achieve the effects of increasing reaction area, good photocatalytic activity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

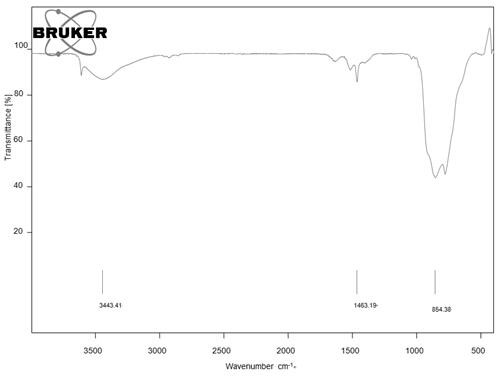

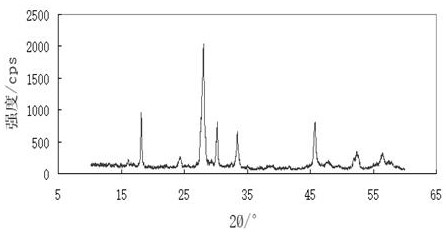

[0032] 1) At 70°C, slowly add 0.25mol / L sodium tungstate solution to 0.6mol / L lanthanum chloride solution, so that the volume ratio of sodium tungstate solution to lanthanum chloride solution is 1.2: 1. Stir fully, and after 1.5 hours of reaction, a white colloidal precursor is obtained;

[0033] 2) Let the colloid precursor obtained in step 1) stand still and settle for 24 hours, then filter it with suction and wash it with distilled water three times to remove impurities, then put it in a drying oven, dry it at 105°C for 24 hours, grind it, and place it in Calcined at 700°C for 5h in a horse-boiling furnace to obtain a white powder which is the photocatalyst La 2 (WO 4 ) 3 .

Embodiment 2

[0035] 1) At 60°C, slowly add 0.50mol / L sodium tungstate solution to 0.9mol / L lanthanum chloride solution, so that the volume ratio of sodium tungstate solution to lanthanum chloride solution is 1.0: 1. Stir fully, and after 1.5 hours of reaction, a white colloidal precursor is obtained;

[0036] 2) Let the colloid precursor obtained in step 1) stand still and settle for 24 hours, then filter it with suction and wash it with distilled water three times to remove impurities, then put it in a drying oven, dry it at 105°C for 24 hours, grind it, and place it in Calcined at 600°C for 5 hours in a horse-boiling furnace to obtain a white powder which is the photocatalyst La 2 (WO 4 )3 .

Embodiment 3

[0038] 1) At 80°C, slowly add 0.70mol / L sodium tungstate solution to 1.0mol / L lanthanum chloride solution, so that the volume ratio of sodium tungstate solution to lanthanum chloride solution is 1.1: 1. Stir fully, and after 1.5 hours of reaction, a white colloidal precursor is obtained;

[0039] 2) Let the colloid precursor obtained in step 1) stand still and settle for 24 hours, then filter it with suction and wash it with distilled water three times to remove impurities, then put it in a drying oven, dry it at 105°C for 24 hours, grind it, and place it in Calcined at a temperature of 650°C for 6 hours in a horse-boiling furnace to obtain a white powder, which is the photocatalyst La 2 (WO 4 ) 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com