Vertical discharging double-layer ore dressing machine

A kind of mineral separator and material cutting technology, applied in sorting and other directions, can solve the problems of limited quality of finished products, large screening particle size, easy wear, etc., to achieve great economic value and improve the effect of sorting accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

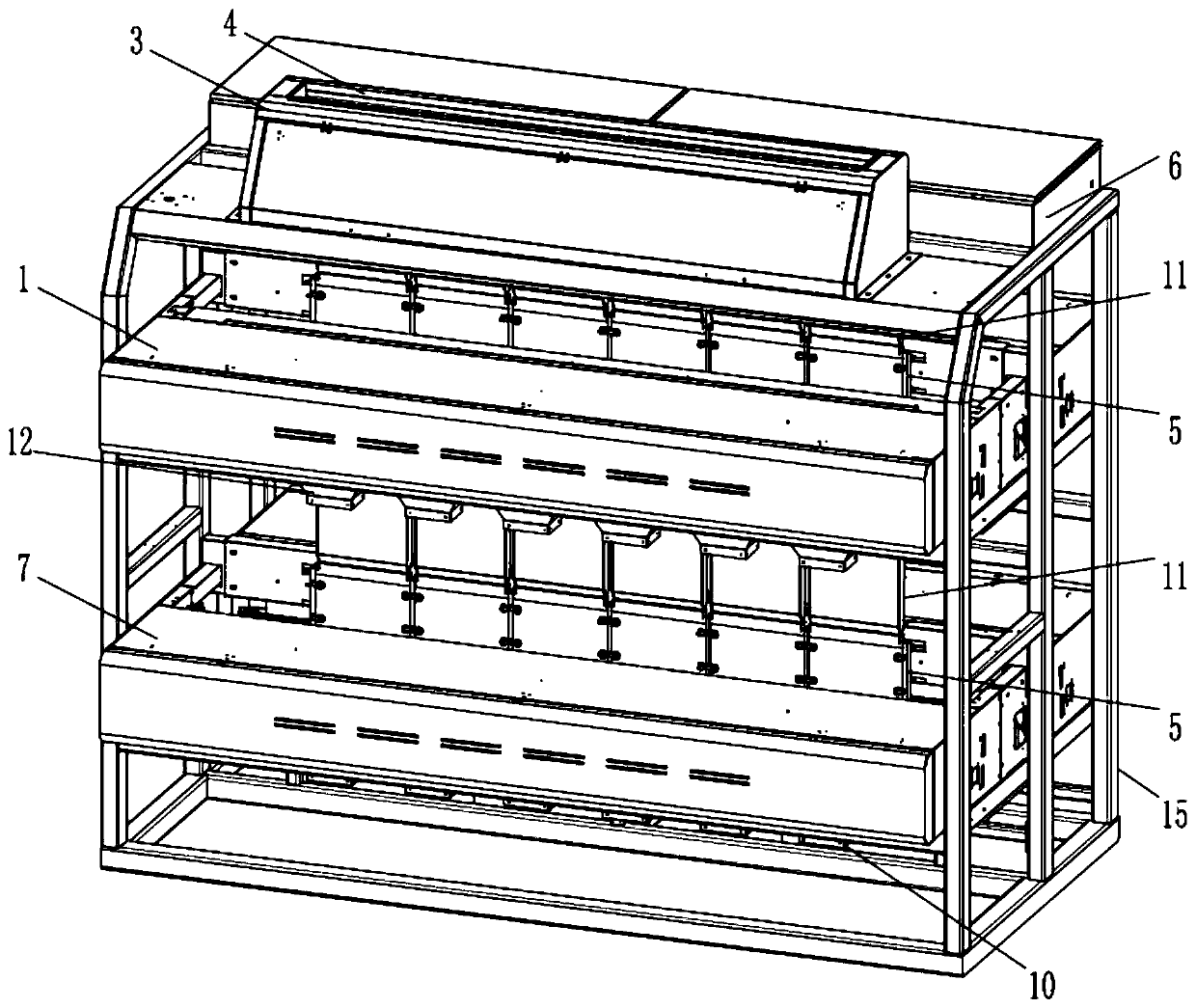

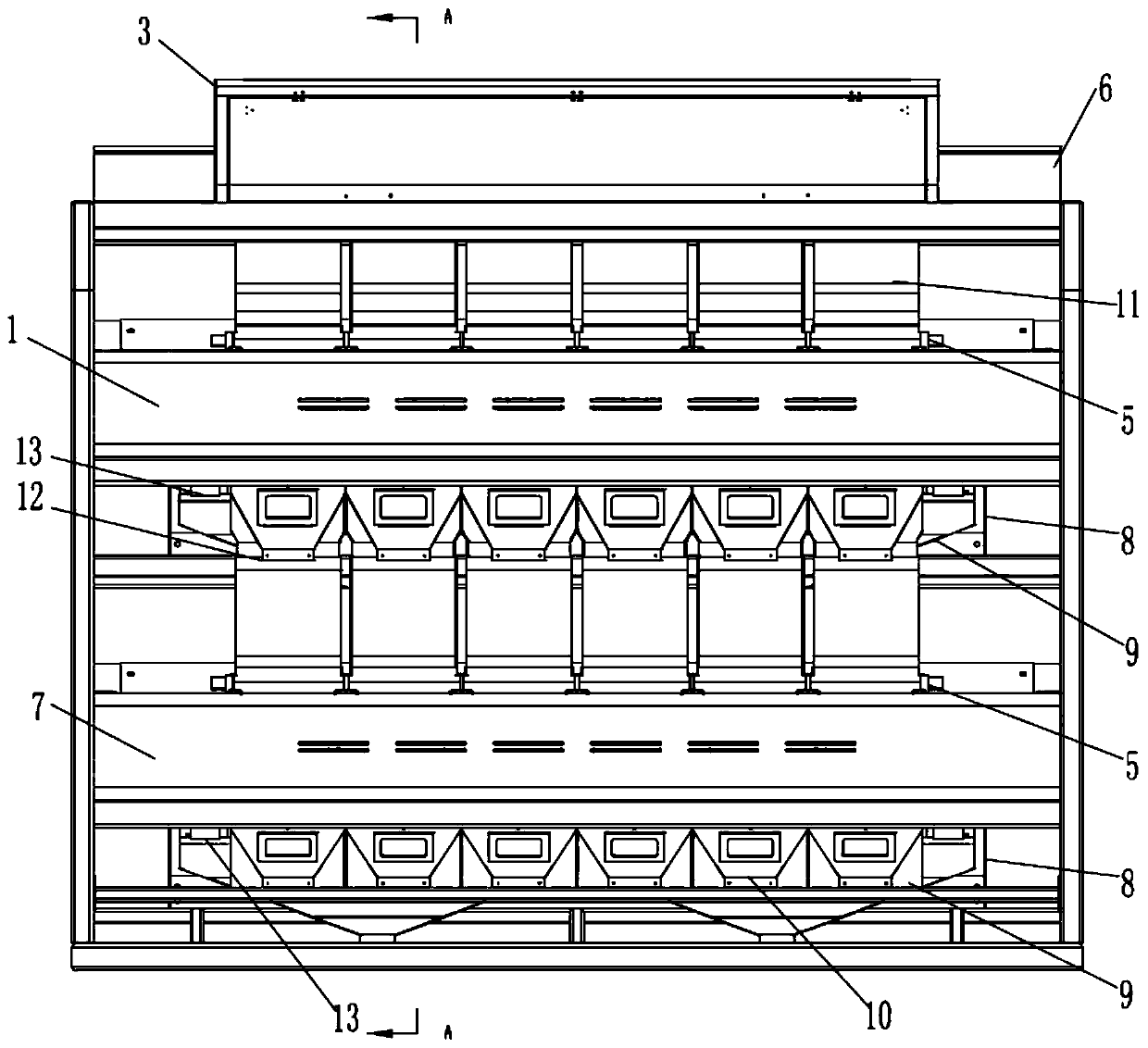

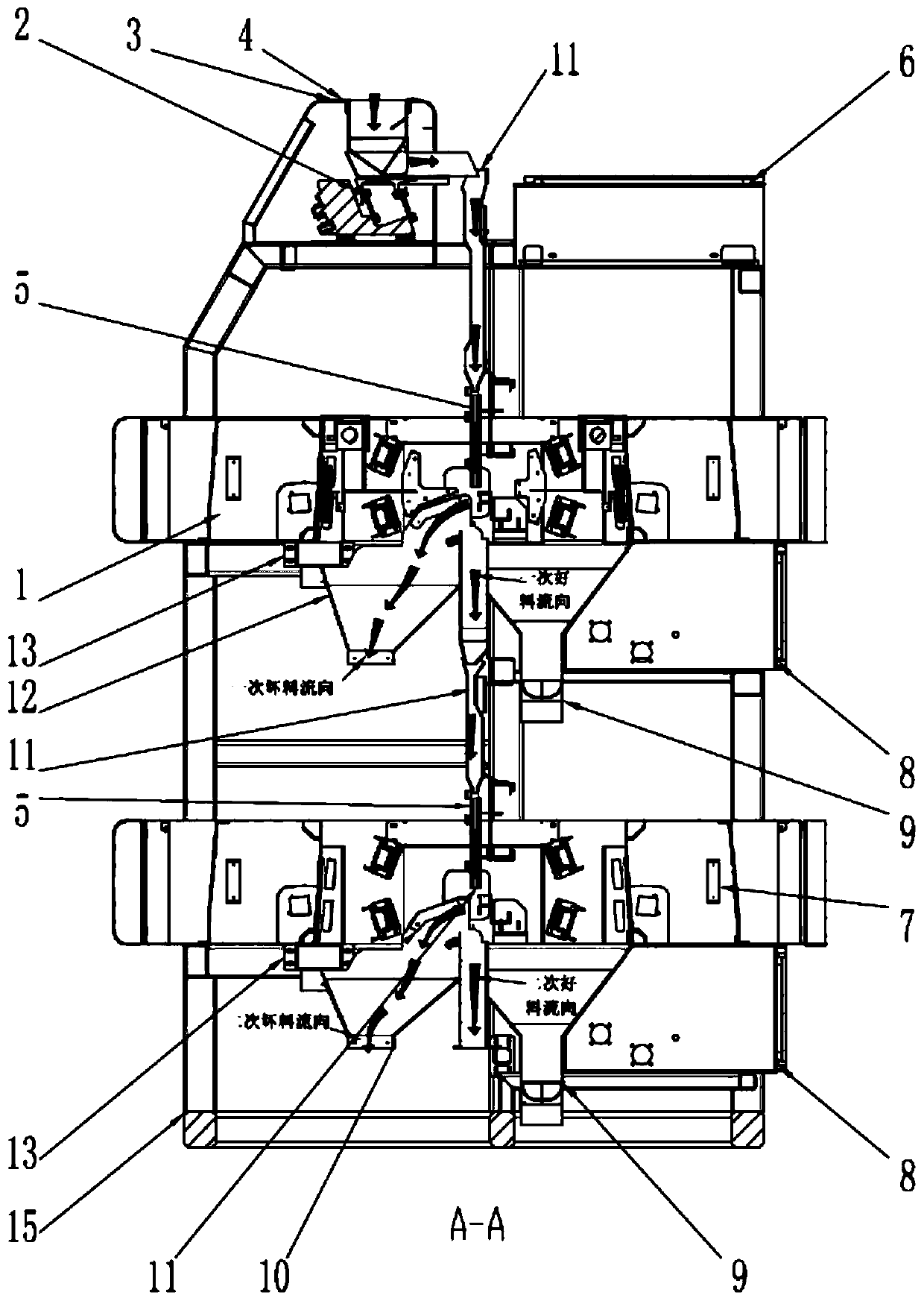

[0025] Such as Figure 1 to Figure 4 Shown, a kind of vertical unloading double-layer ore separation machine, comprises frame 15 and is installed on the frame 15 feeding hopper support 3, electric control box 6, vibrating bucket 2, sorting box A1, sorting box B7, Valve box 8, overflow hopper 9, feeding chute 14, feeding hopper 4 is installed on feeding hopper support 3, the bottom of sorting box A1 is connected to upper layer discharging hopper 12, the bottom of sorting box B7 is connected to lower layer discharging hopper 10, feeding hopper 4 It is connected with the vibrating bucket 2, and the vibrating bucket 2 is connected with the sorting box A1 through the feeding chute 14, and the qualified product notch of the upper discharge hopper 12 at the bottom of the sorting box A1 is connected with the sorting box B7 through the feeding chute 14 Pass; The blanking chute 14 is vertically installed on the frame 15, and the blanking chute 14 is made up of the material guide chute 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com