Crate washing machine for bottle crates and method for removing adhesive labels from bottle crates

A technology of box washer and bottle box, which is applied in the field of box washer, can solve the problems of unreliable and troublesome removal, and achieve the effect of reducing liquid consumption and improving efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

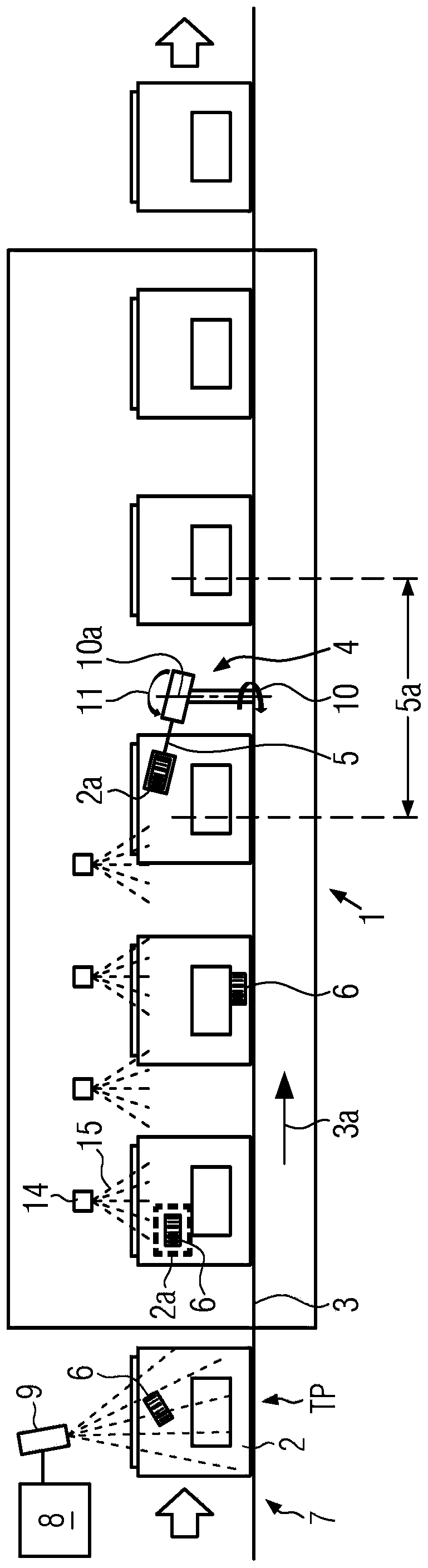

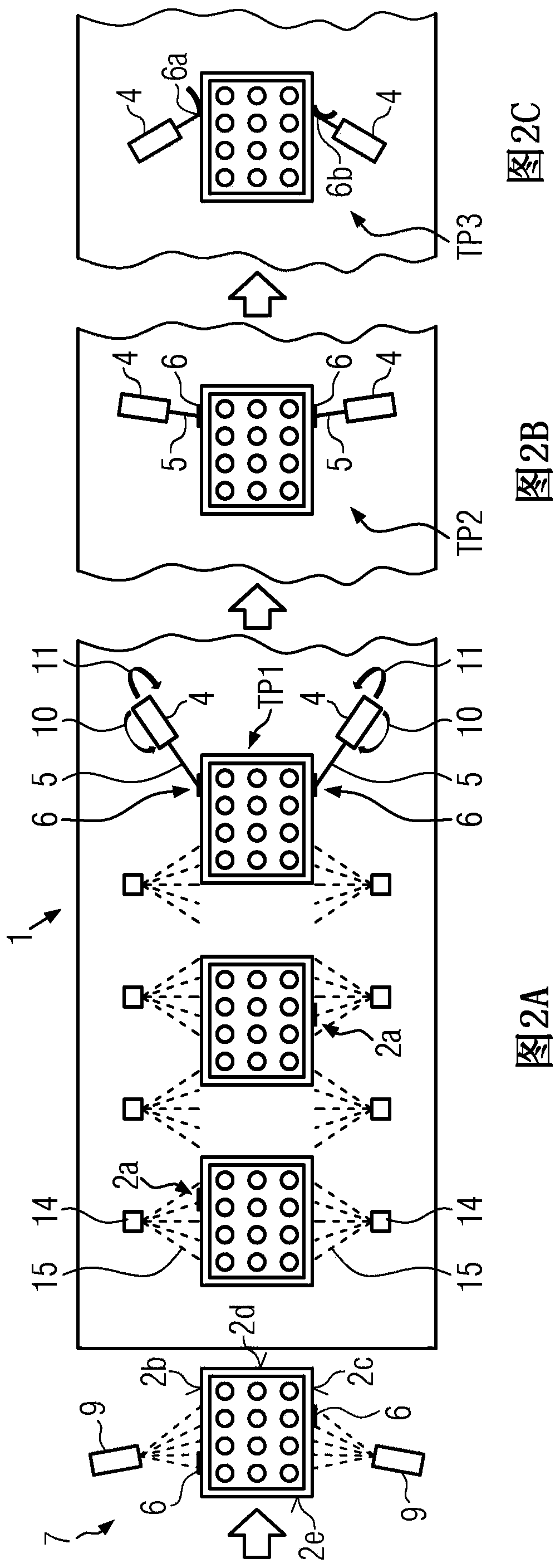

[0032] as by figure 1 It can be seen that the case washer 1 for the bottle cases 2 comprises, in a preferred embodiment, a transport mechanism 3 for the bottle cases 2 and for spraying the transported bottle cases 2 in the form of a deflectable high-pressure jet 5 At least one movable nozzle 4 of cleaning fluid.

[0033] On the bottle case 2 there is an adhesive label 6 to be peeled off in the case washer 1 . To this end, the case washing machine 1 comprises an inspection unit 7 on the input side for identifying and position-fixing the identified adhesive labels 6 and for selectively aligning the nozzles 4 with the adhesive labels at the determined positions. The label 6 and / or the control unit 8 of the bottle case 2 is assigned to the target area 2 a of these adhesive labels.

[0034] The control unit 8 and the nozzle 4 generate a high-pressure jet 5 which can be switched on in a targeted manner and which can be redirected in the associated working region 5 a. For this pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com