Electric hand drill with drill bit cooling function

A hand electric drill and drill bit technology, used in drilling/drilling equipment, manufacturing tools, portable drilling rigs, etc., can solve the problems of large impact on the life of the drill bit and poor cooling effect of the drill bit, so as to ensure the effective working depth and reduce the vibration sense. , the effect of improving the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

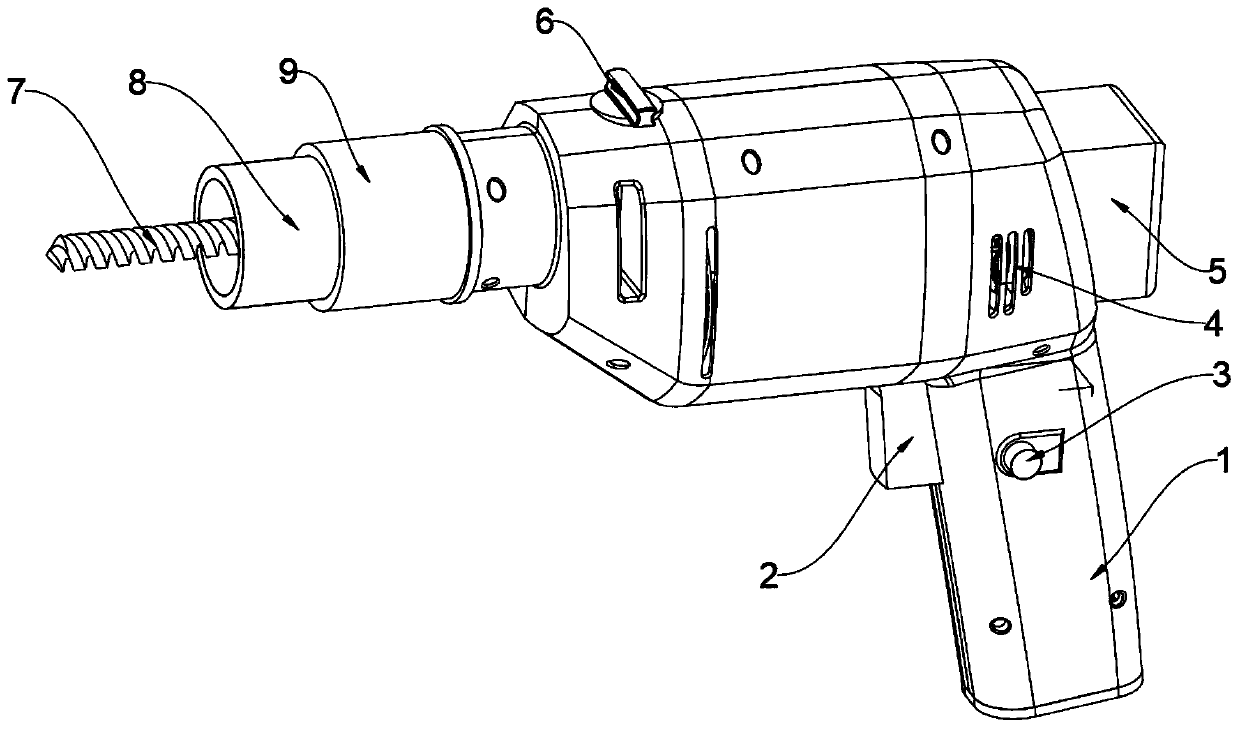

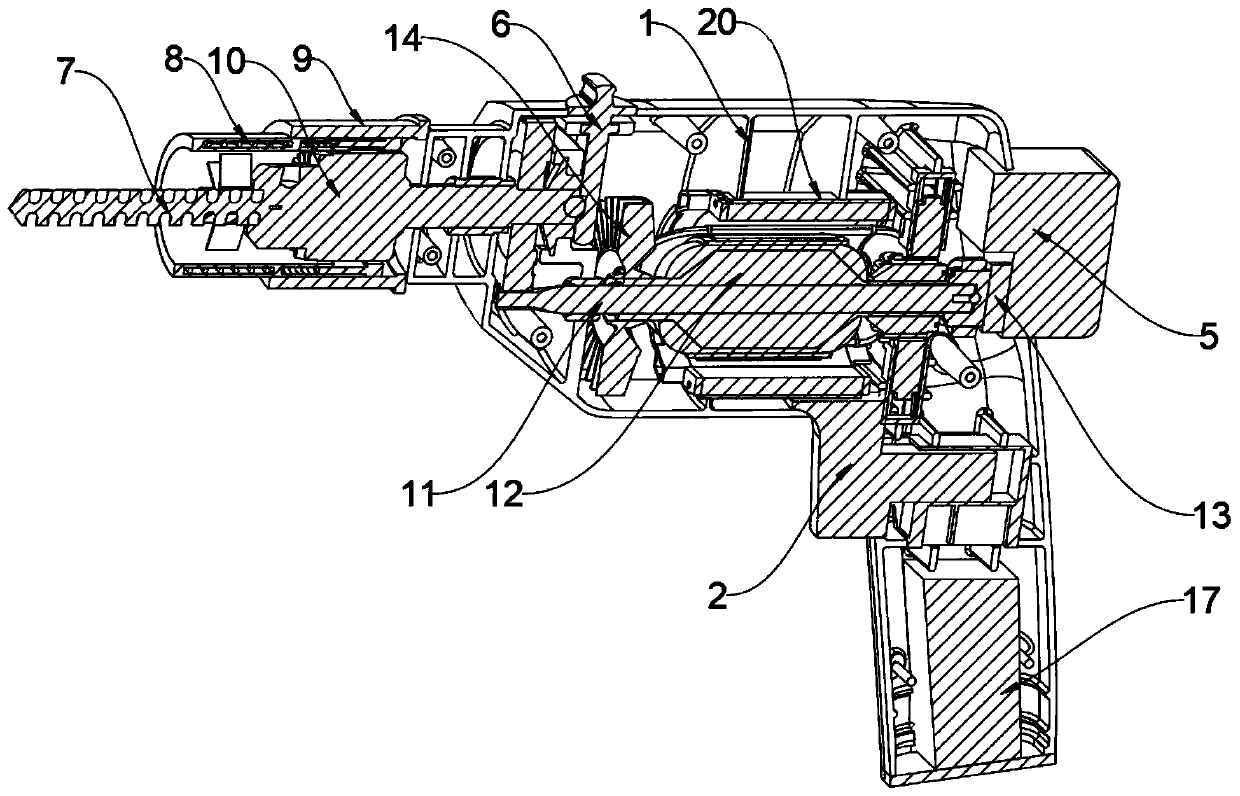

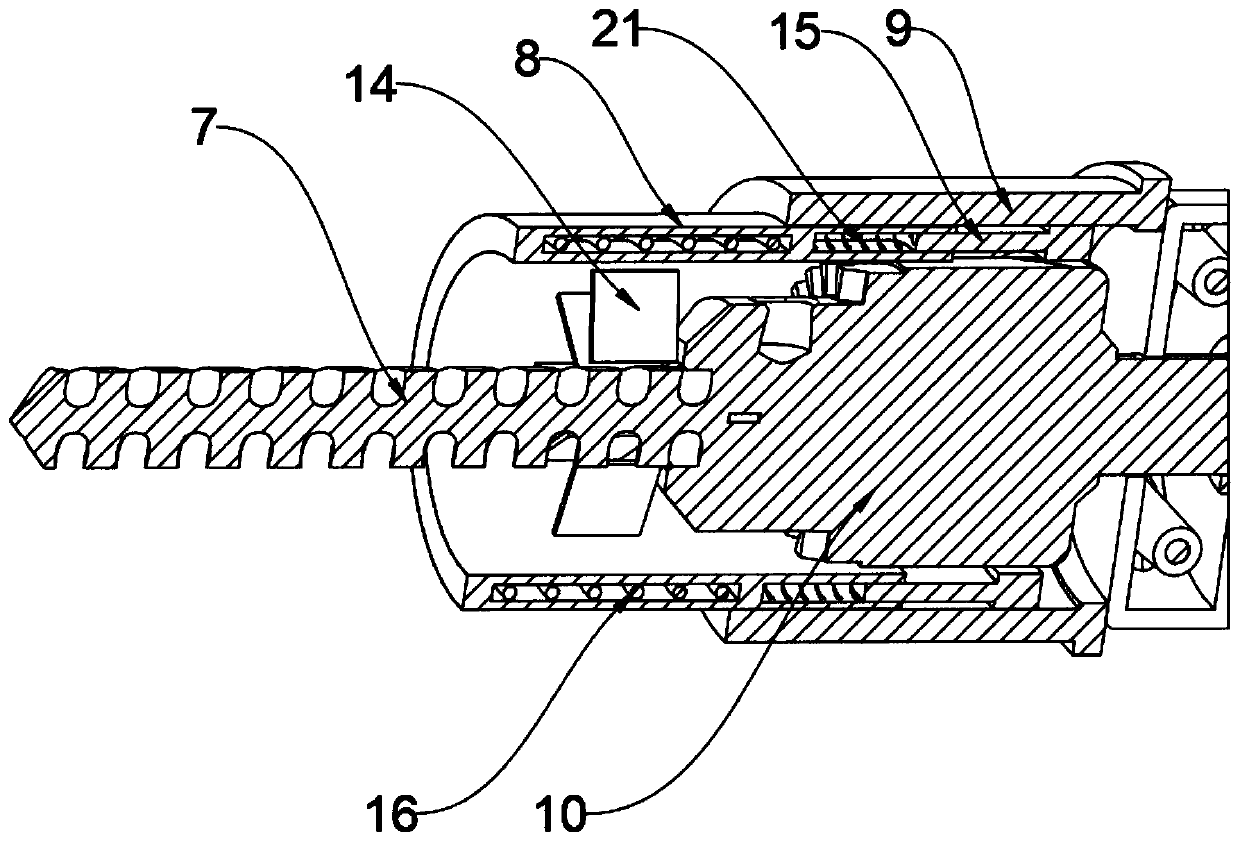

[0030] Example 1: See Figure 1-4 , an embodiment provided by the present invention: a hand electric drill with a drill bit cooling function, including a bottom cover 18, a battery 17 is installed on the lower end surface of the bottom cover 18, a battery limiting plate 19 is installed above the battery 17, and the battery limiting A switch 2 is installed on the top of the bit plate 19, a reverse button 3 is installed on the front end of the switch 2, a housing 1 is installed on the outside of the switch 2, a heat dissipation port 4 is installed on the front end of the housing 1, and the inside of the heat dissipation port 4 is installed. Connection box 13 is arranged, and water tank 5 is installed on one end of connection box 13, and motor shaft 11 is installed on the other end of connection box 13, and motor 12 is installed on the outside of motor shaft 11, and buffer pad 20 is installed on the outside of motor 12, and motor 12 Radiating blades 14 are installed on one side, ...

Embodiment 2

[0044] Embodiment 2: In this embodiment, the spiral winding mode of the spiral water pipe outside the water pipe sleeve 8 is added. In addition, the spiral water pipe is made of easy plastic material, and a spiral water pipe is respectively arranged on the two connecting pipes of the water tank 5. The airbag, the outlet and the inlet of the airbag are in a state of natural contraction when they are not connected. The specific working process of this embodiment is as follows:

[0045] The helical winding method makes the water pipe sleeve 8 move inside the continuous damping of the main sleeve 9, which effectively ensures the effective working depth of the drill bit and ensures the uniformity of the drill bit. In addition, the helical winding method is similar to The compression of the spring, during the working process of the drill bit, the heat generated and the compression of the water pipe itself make the air and water in it partially extruded, causing the pressure in the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com