Chain climbing robot for detecting mooring chain of offshore floating platform and offshore operation method of chain climbing robot

A floating platform and mooring chain technology, applied in the field of chain-climbing robots, can solve the problems of staying in the theoretical analysis and design stage, operation capacity limitation, long construction period, etc., to improve the underwater operation time and operation depth, guarantee Accuracy and reliability, the effect of low relative motion amplitudes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

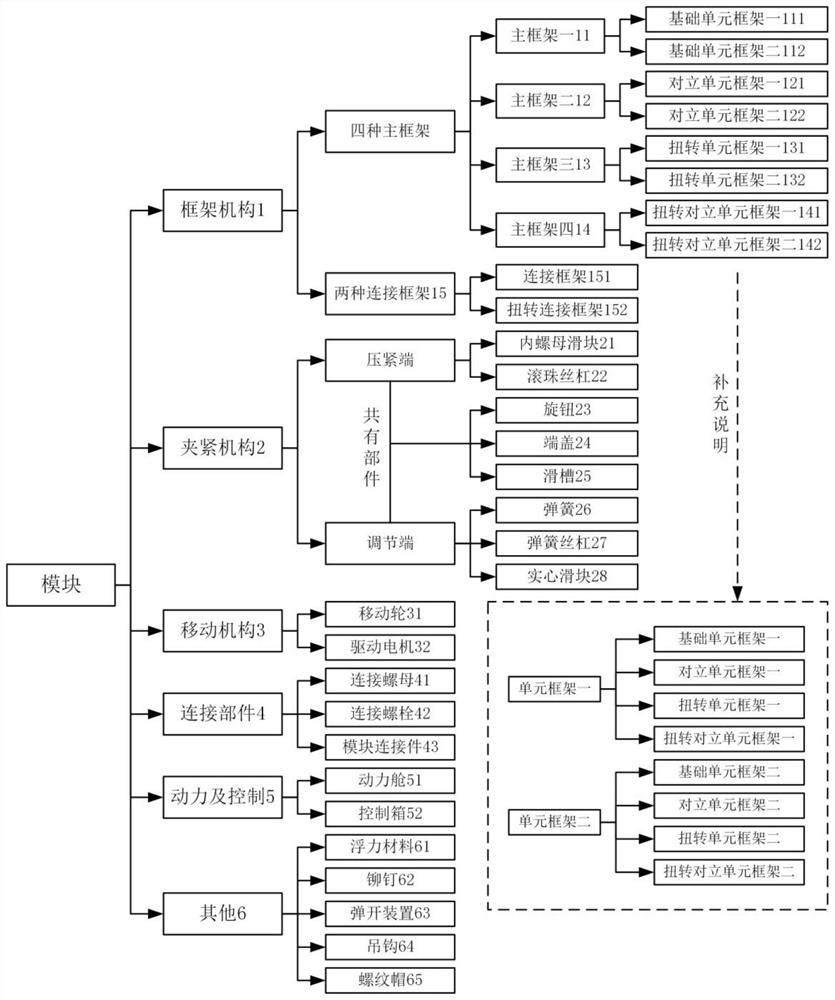

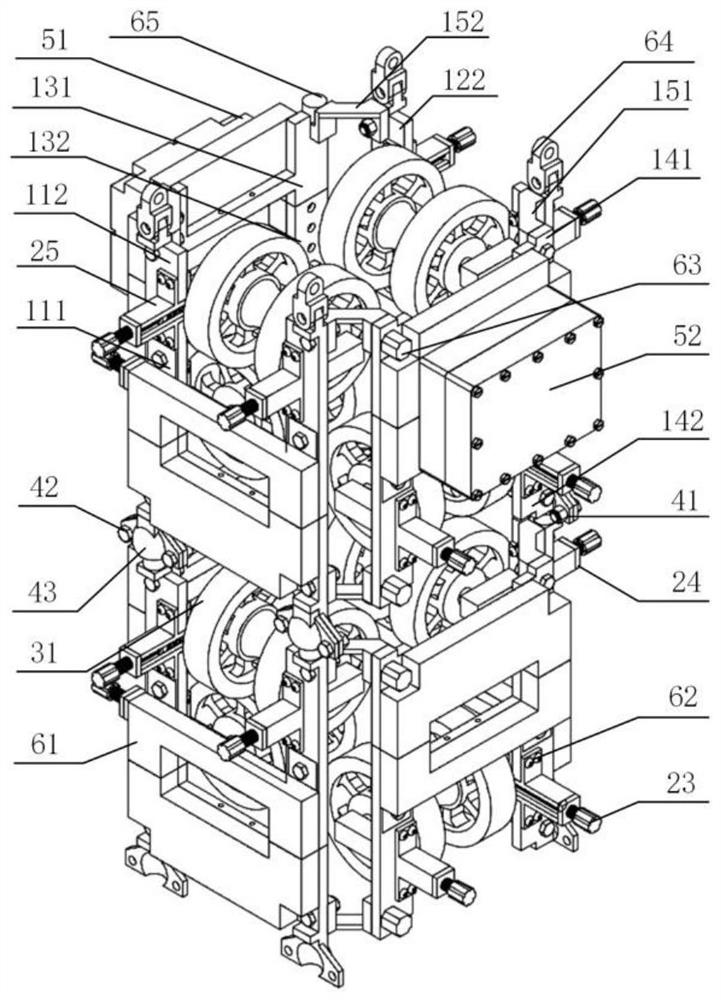

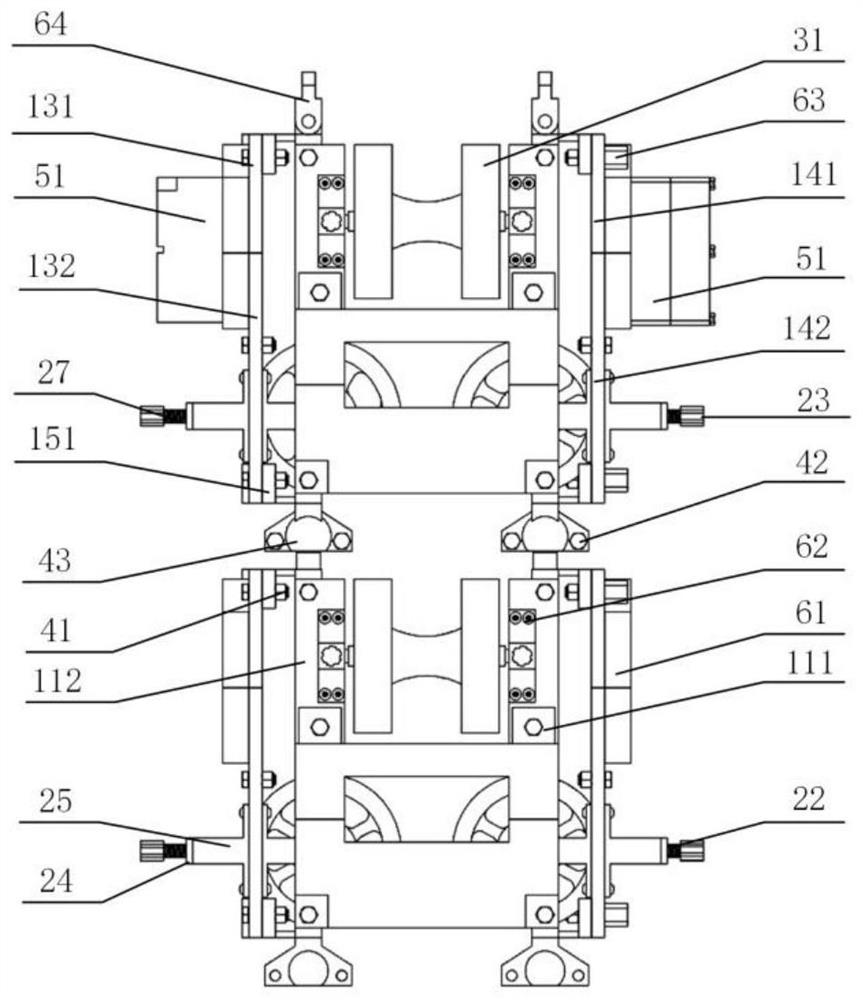

[0049] refer to figure 2 , 3 , 4, 5, and 11, a chain climbing robot used for detection of mooring chains on offshore floating platforms is composed of several modules connected by module connectors 43 . refer to figure 1 As shown, the module includes a frame mechanism 1, a clamping mechanism 2, a moving mechanism 3, a connecting part 4, a power and control mechanism 5, and other parts 6. The frame mechanism 1 is an octagonal prism shape structure, and the frame The mechanism is composed of four main frames, connecting frame 151, and twisting connecting frame 152 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com