Dustproof wall surface grinding machine

A grinding machine and dust-proof technology, applied in machine tools, grinders, grinding/polishing equipment suitable for grinding workpiece planes, etc., can solve the problems of low grinding efficiency, poor dust-proof effect, inconvenient cleaning, etc., and achieve grinding efficiency. High, prevent scattering around, prevent dust from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

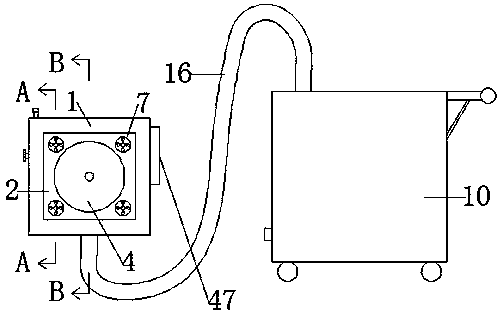

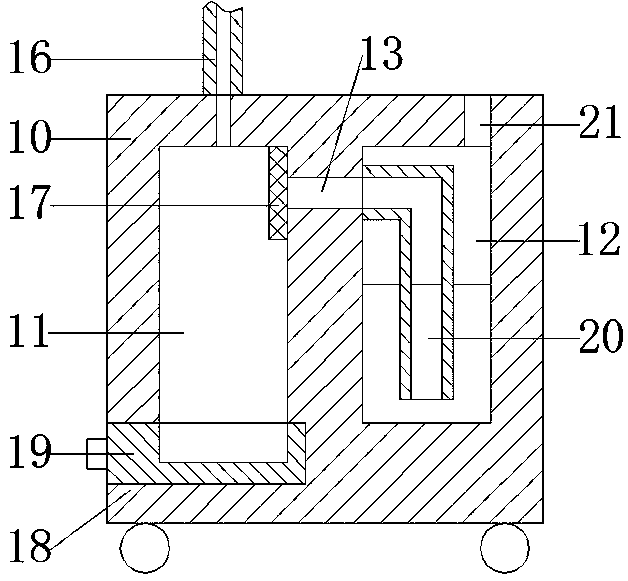

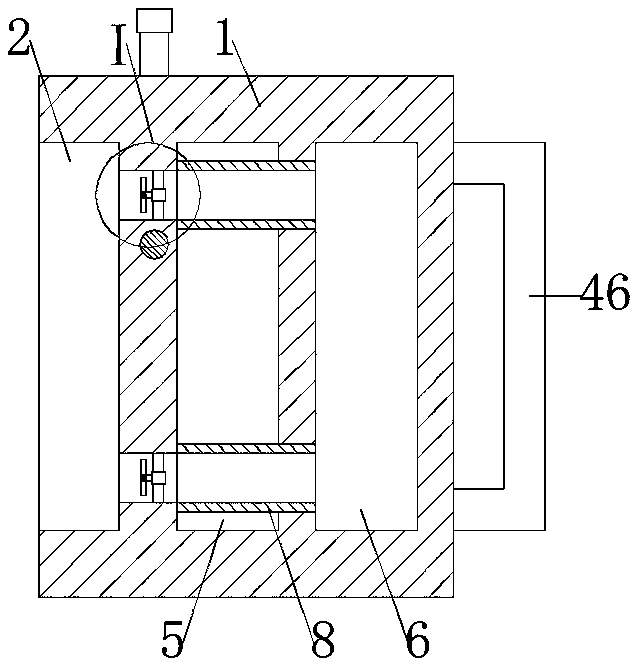

[0032] Such as Figure 1 to Figure 12 As shown, a dust-proof wall grinder includes a mounting base 1, the front end of the mounting base 1 is provided with a rectangular groove 2, and a spindle 3 extending forward and backward is installed in the rectangular groove 2. On the spindle 3 A grinding disc 4 located in the rectangular groove 2 is fixedly installed; a drive chamber 5 and a dust collection chamber 6 are provided in the front and back of the mounting seat 1 in sequence, and the four corners of the rectangular groove 2 are provided with a rearward extension and communicated with the Four circular grooves 7 of the driving chamber 5, the connecting pipe 8 connecting the circular groove 7 and the dust collecting chamber 6 is arranged in the driving chamber 5, and the first fan 9 is arranged in the circular groove 7, through which The first blower 9 transports the dust generated in the grinding process to the dust collection chamber 6 to prevent the dust from overflowing agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com