A New Vehicle Powertrain Mounting Device

An automobile powertrain and mount technology, applied in the direction of power devices, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of reducing the development and production costs of hydraulic mounts, and achieve good vibration and noise reduction effects and long service life The effect of lifting, high vibration absorption capacity and shock-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

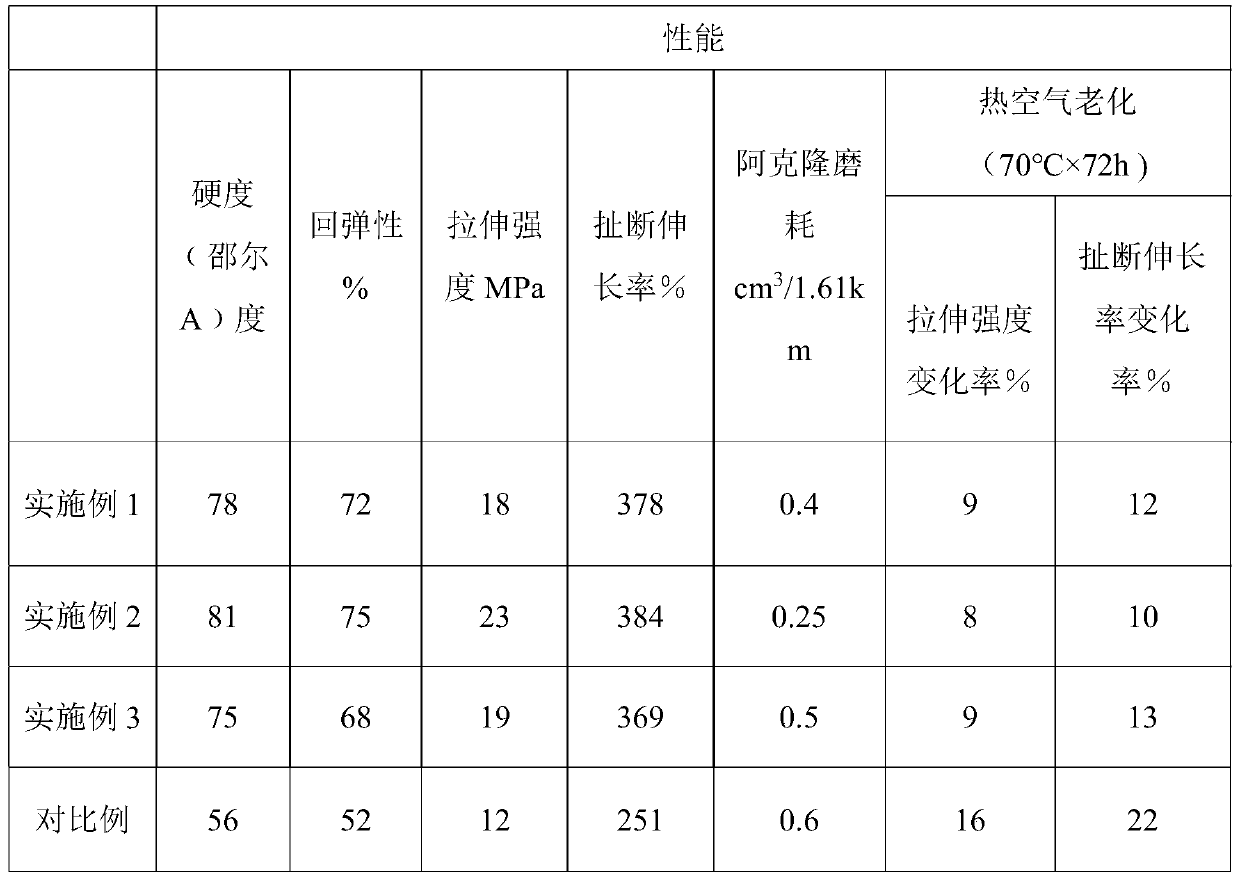

Embodiment 1

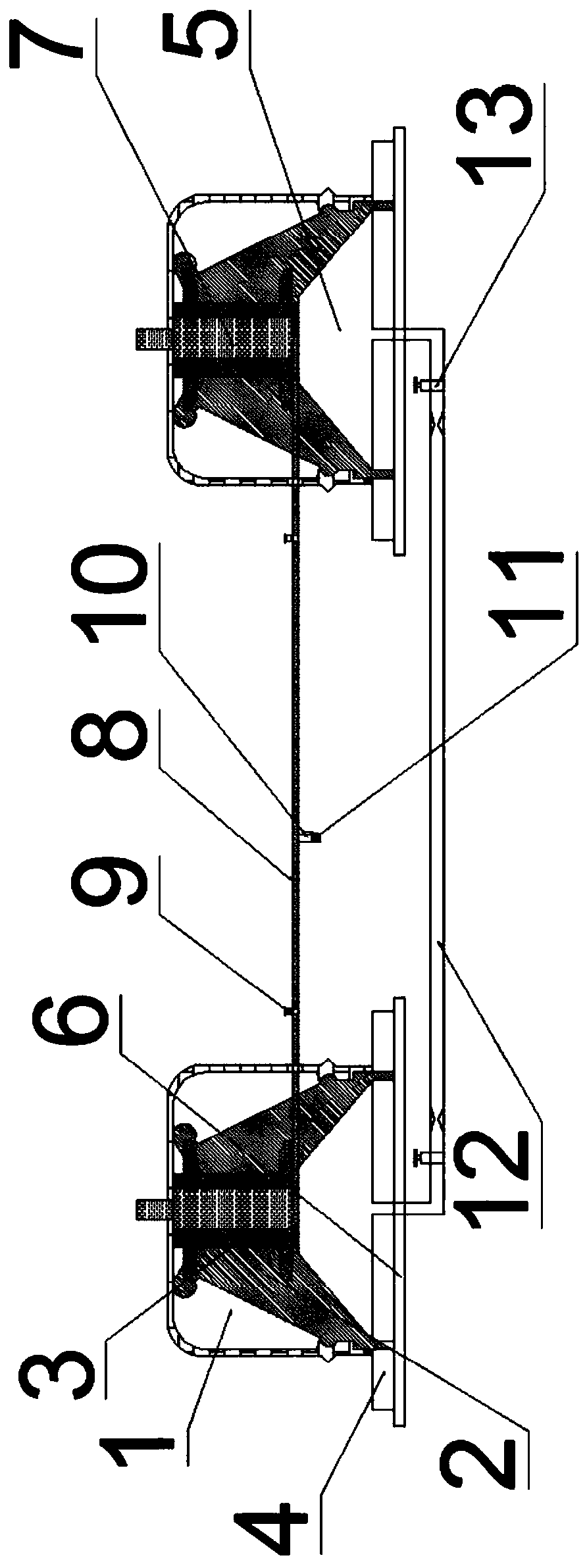

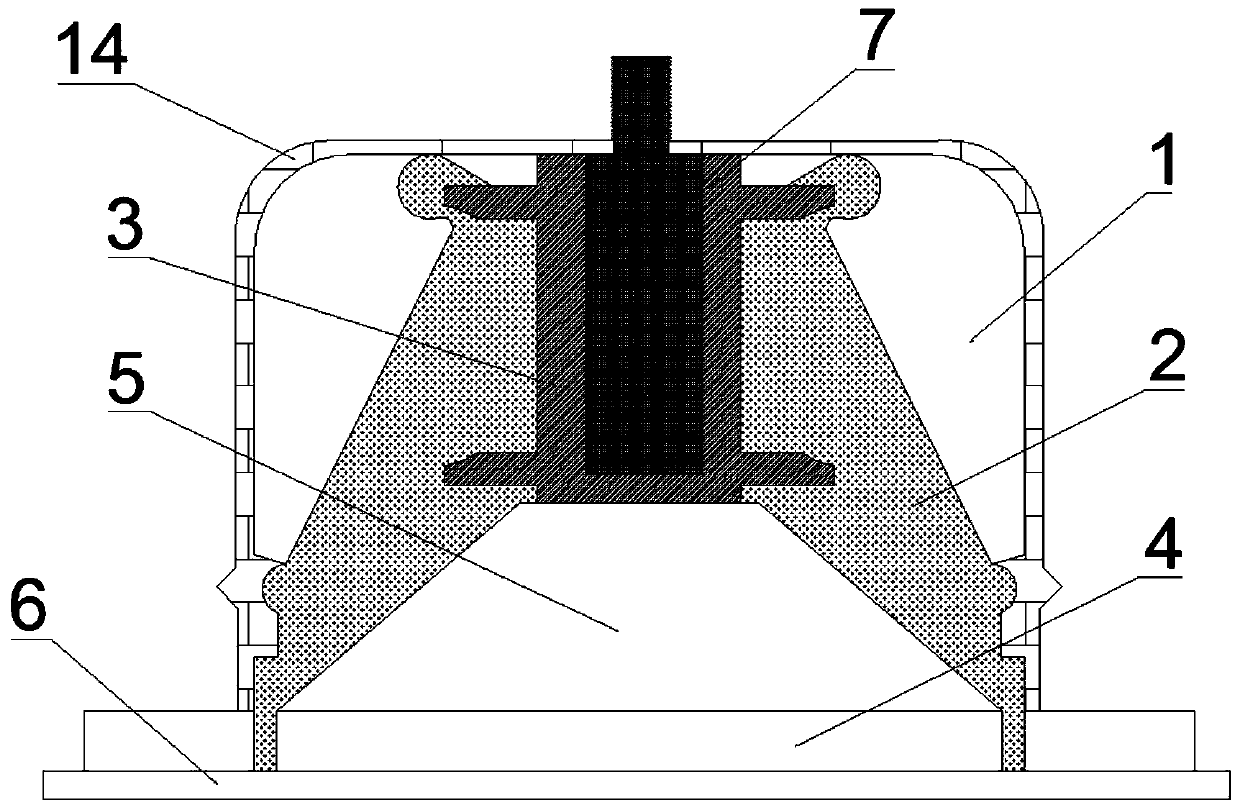

[0026] An automobile powertrain suspension device, comprising two assembly suspensions 1, the two assembly suspensions 1 are installed on the engine symmetrically, and the assembly suspension 1 includes an elastic main spring 2, a buffer device, core 3 and bottom plate 4, the elastic main spring 2 and core 3 are fixed by vulcanization, a cavity 5 is formed between the elastic main spring 2 and the bottom plate 3, and the buffer device is installed on the core Inside the sub 3, a fixed plate 6 is installed on the outside of the bottom plate 4, and the fixed plate 6 is connected to the frame by welding, and the core 3 is installed in the limit cover 14; the assembly suspension 1 under different working conditions The effect is not the same, especially under the typical low-frequency large-amplitude excitation conditions and high-frequency small-amplitude excitation conditions, the dynamic characteristics are different. Specifically, when the car is driving on a rough road , the ...

Embodiment 2

[0039] An automobile powertrain suspension device, comprising two assembly suspensions 1, the two assembly suspensions 1 are installed on the engine symmetrically, and the assembly suspension 1 includes an elastic main spring 2, a buffer device, core 3 and bottom plate 4, the elastic main spring 2 and core 3 are fixed by vulcanization, a cavity 5 is formed between the elastic main spring 2 and the bottom plate 3, and the buffer device is installed on the core Inside the sub 3, a fixed plate 6 is installed on the outside of the bottom plate 4, and the fixed plate 6 is connected to the frame by welding, and the core 3 is installed in the limit cover 14; the assembly suspension 1 under different working conditions The effect is not the same, especially under the typical low-frequency large-amplitude excitation conditions and high-frequency small-amplitude excitation conditions, the dynamic characteristics are different. Specifically, when the car is driving on a rough road , the ...

Embodiment 3

[0052] An automobile powertrain suspension device, comprising two assembly suspensions 1, the two assembly suspensions 1 are installed on the engine symmetrically, and the assembly suspension 1 includes an elastic main spring 2, a buffer device, core 3 and bottom plate 4, the elastic main spring 2 and core 3 are fixed by vulcanization, a cavity 5 is formed between the elastic main spring 2 and the bottom plate 3, and the buffer device is installed on the core Inside the sub 3, a fixed plate 6 is installed on the outside of the bottom plate 4, and the fixed plate 6 is connected to the frame by welding, and the core 3 is installed in the limit cover 14; the assembly suspension 1 under different working conditions The effect is not the same, especially under the typical low-frequency large-amplitude excitation conditions and high-frequency small-amplitude excitation conditions, the dynamic characteristics are different. Specifically, when the car is driving on a rough road , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com