Automatic leveling method for supporting legs

An automatic leveling and outrigger technology, which is applied in vehicle maintenance, load suspension components, lifting vehicle accessories, etc., can solve the problems of low leveling accuracy and achieve high leveling efficiency, high leveling accuracy, and leveling The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

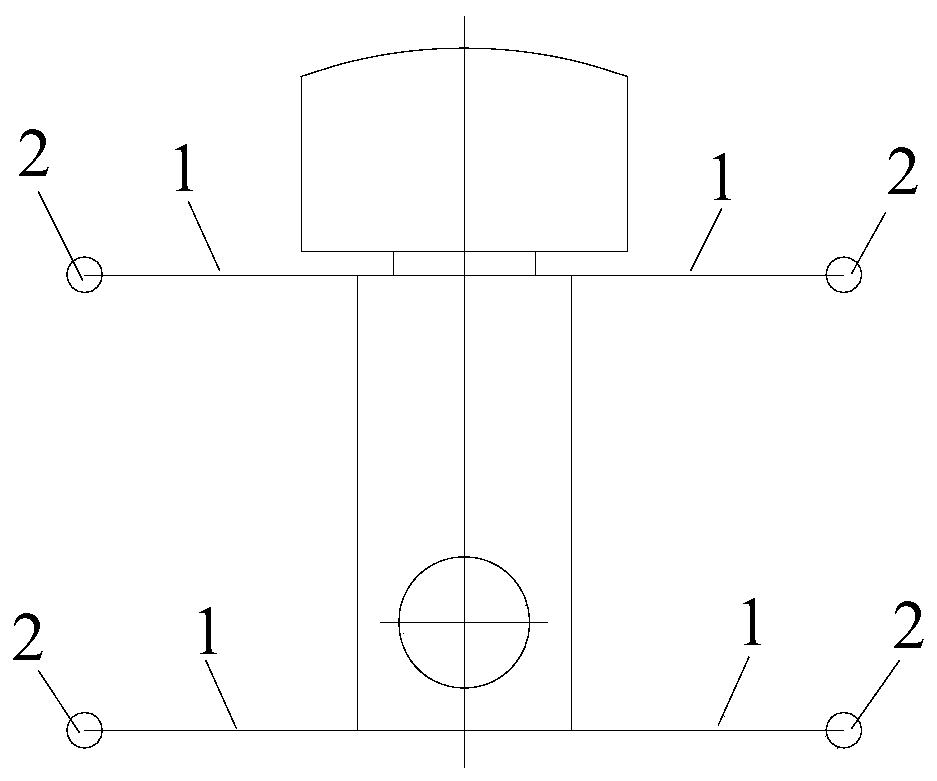

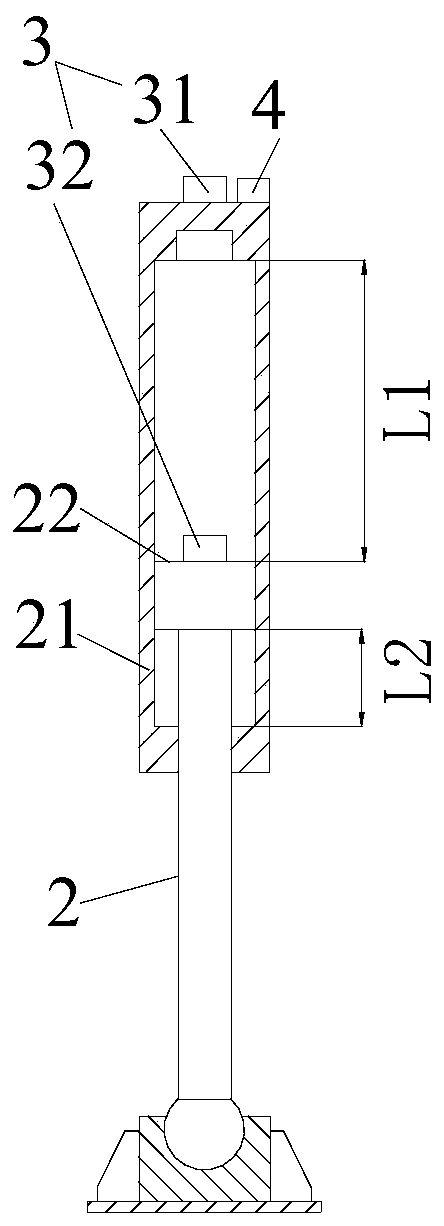

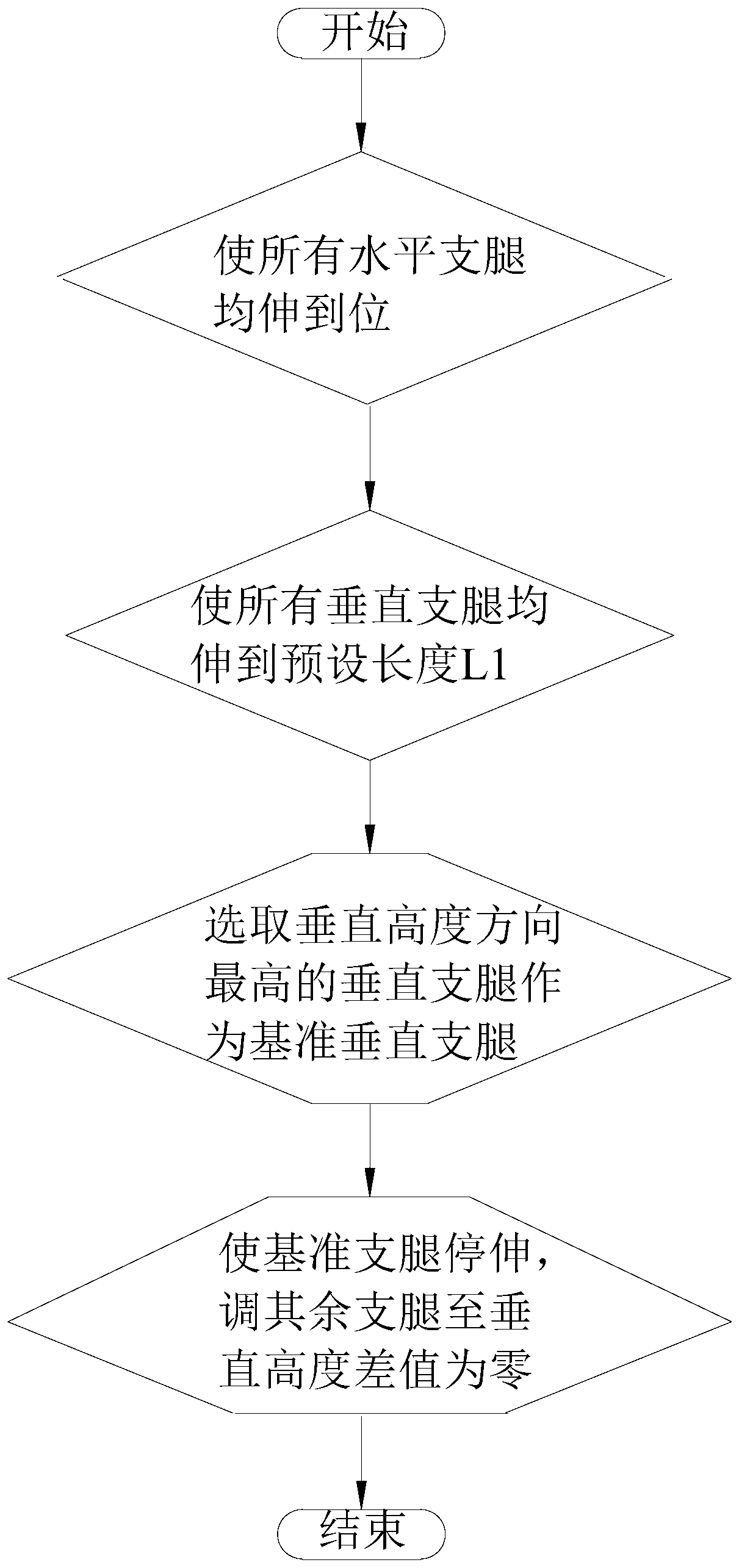

[0030] Please combine figure 1 with figure 2 Shown: an automatic leveling method for outriggers provided in this embodiment, the outriggers include horizontal outriggers 1 and vertical outriggers 2, and each vertical outrigger 2 is respectively equipped with a The absolute displacement sensor 3 and the relative displacement sensor 4 that obtains the vertical height difference of the vertical support leg relative to the reference vertical support leg; the absolute displacement sensor 3 includes a detector 31 and a trigger 32, and the detector 31 is installed on each vertical support On the cylinder barrel 21 of the leg 2, the trigger 32 is installed at the maximum preset stroke position 22 of each vertical leg 2. Described relative displacement sensor 4 selects laser displacement sensor for use, and described relative displacement sensor 4 is installed on the oil cylinder tube 21 of all vertical supporting legs 2, and the relative displacement sensor 4 installed on all vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com