Polyacrylate copolymer leveling agent, and preparation method and application method thereof in enameled wire enamel

A technology of polyacrylate and enameled wire varnish, applied in the direction of coating, etc., can solve the problems of short leveling time, slow leveling speed, poor temperature resistance, etc., to improve leveling speed, concentrate molecular weight distribution, and improve heat resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

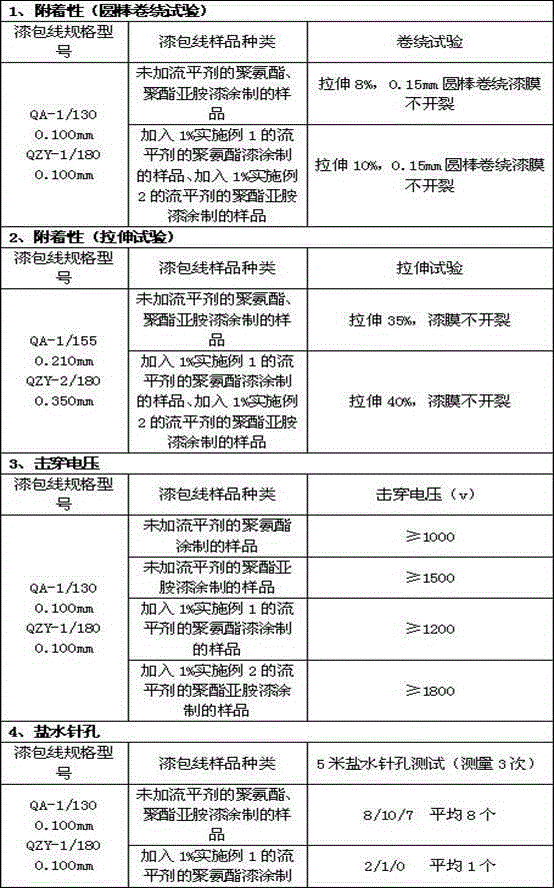

Examples

Embodiment 1

[0045] Embodiment 1, carry out according to the following steps:

[0046] 1. Add 600 grams of xylene of component E into a 2000 ml four-port tank reactor equipped with a stirrer, thermometer, nitrogen conduit, reflux condenser, and dropping funnel at one time, then stir, and then pass it into the nitrogen replacement tank The air in the type reactor and preheating component E to 95°C, the introduction of nitrogen must be kept until the entire reaction process is completed;

[0047] 2. Put 400 grams of octyl acrylate in component A, 100 grams of β-hydroxyethyl acrylate in component B, 3 grams of dibenzoyl peroxide in component C, and 2 grams of dodecyl mercaptan in component D in a beaker Mix evenly in advance, add 25% of the mixed solution into the tank reactor, raise the temperature to 105°C within one hour, and observe the obvious self-acceleration effect of the system, keep the reaction temperature at 105°C and complete the dropwise addition within three hours remaining mi...

Embodiment 2

[0057] Embodiment 2, carry out according to the following steps:

[0058] 1. In a tank reactor with a stirrer, a thermometer, a nitrogen conduit, a reflux condenser, and a dropping funnel with 2000 milliliters of four ports, nitrogen is introduced to replace the air in the tank reactor and kept until the entire reaction process is completed;

[0059] 2. Take 200 grams of diethylhexyl acrylate and 200 grams of lauryl acrylate in component A, 80 grams of β-hydroxypropyl acrylate and 12 grams of acrylic acid in component B, and 3 grams of dibenzoyl peroxide in component C. , D component dodecyl mercaptan 4 grams pre-mixed evenly in a beaker, after mixing, take 25% of the total mass of the mixture and add it to the tank reactor, stir and raise the temperature to 105°C, and keep the temperature at 105°C for one hour , after observing the obvious self-acceleration effect of the system, add the remaining mixed liquid into the tank reactor in 4 to 5 times within 4 hours. After the add...

Embodiment 3

[0063] Example 3, 500 grams of lauryl acrylate in component A, 25 grams of methacrylic acid in component B, 0.52 grams of azobisisobutyronitrile in component C, and 1.58 grams of dodecyl mercaptan in component D, 525 grams of E component solvent xylene was operated according to the device and steps described in Example 1 to prepare a similar acrylate copolymer leveling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com