Rotary loading machine

A technology of loader and slewing mechanism, which is applied in the direction of earth mover/excavator, mechanically driven excavator/dredger, construction, etc., which can solve the problem of affecting the progress and efficiency of loading operations, the narrow space of the working site, and the joint working mechanism Rotation and other problems, to achieve the effect of increasing the environmental adaptability of loading operations, small turning space, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

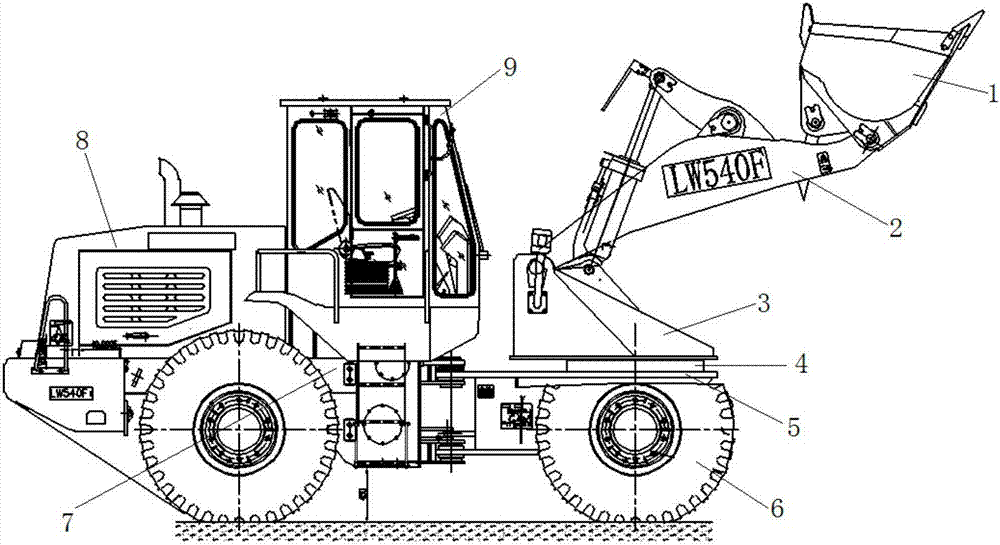

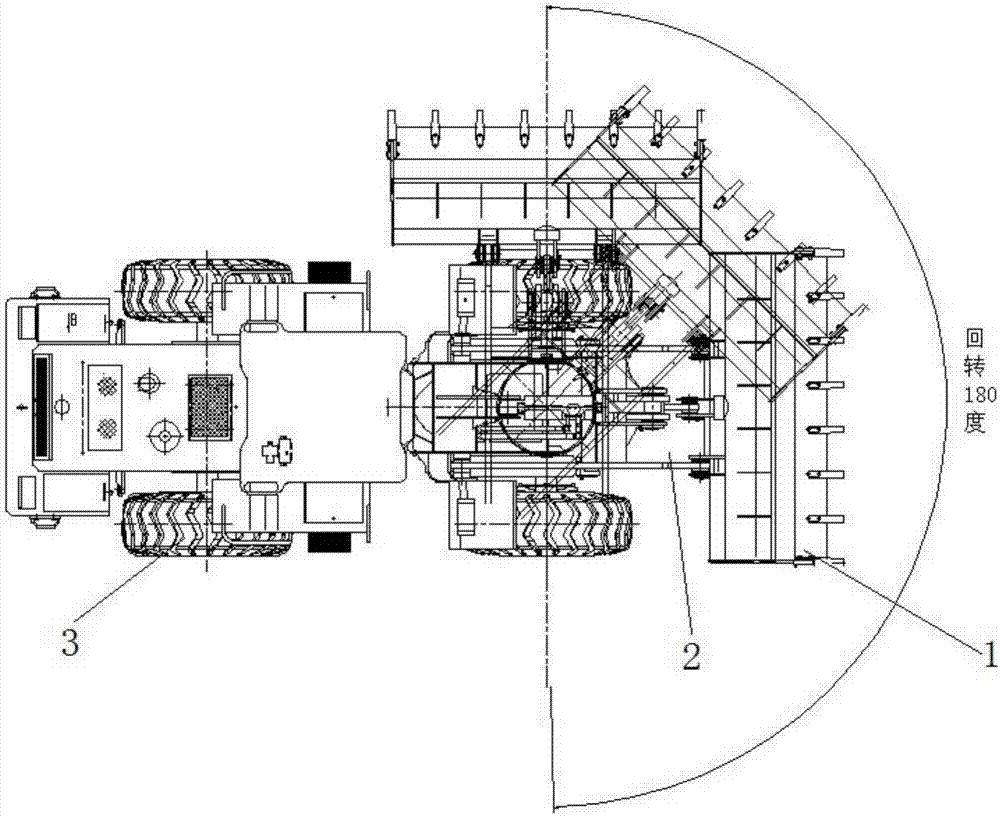

[0037] Such as figure 1 and figure 2 As shown, the present invention provides a kind of slewing loader, comprising: working mechanism, slewing mechanism 4, chassis mechanism, power mechanism 8 and driver's cab 9; It includes a hydraulic lifting arm 2 with a loading bucket 1 at the front end and a slewing bracket 3, the hydraulic lifting arm 2 is set on the slewing bracket 3, the chassis mechanism includes a loader front frame 5, and the slewing mechanism 4 is located at Between the slewing bracket 3 and the front frame 5 of the loader, the slewing mechanism 4 drives the working mechanism to turn left and right during work, and the driver's cab 9 is set independently and does not rotate with the slewing mechanism 4. The turning mechanism 4 drives the working mechanism to turn left and right by a maximum of 90 degrees, and the turning mechanism 4 includes a driving motor, and the driving motor is a hydraulic motor. The power mechanism 8 includes a diesel engine. The chassis ...

Embodiment 2

[0039] The present invention provides a slewing loader, comprising: a working mechanism, a slewing mechanism 4, a chassis mechanism, a power mechanism 8 and a cab 9; the working mechanism is located at the front of the cab 9, and the working mechanism includes a front end There is a hydraulic lifting arm 2 and a slewing bracket 3 of a loading bucket 1, the hydraulic lifting arm 2 is arranged on the slewing bracket 3, the chassis mechanism includes a loader front frame 5, and the slewing mechanism 4 is located on the slewing frame Between the bracket 3 and the front frame 5 of the loader, the slewing mechanism 4 drives the working mechanism to turn left and right during work, and the cab 9 is set independently and does not rotate with the slewing mechanism 4. The slewing mechanism 4 The working mechanism is driven to rotate at a maximum of 90 degrees left and right respectively, and the turning mechanism 4 includes a driving motor, and the driving motor is an electric motor. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com