Asphalt pavement leveling device

An asphalt pavement and leveling technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of affecting the normal use of roads, high road maintenance costs, cumbersome repair process, etc., to reduce repair costs, reduce temperature, and reduce equipment structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described:

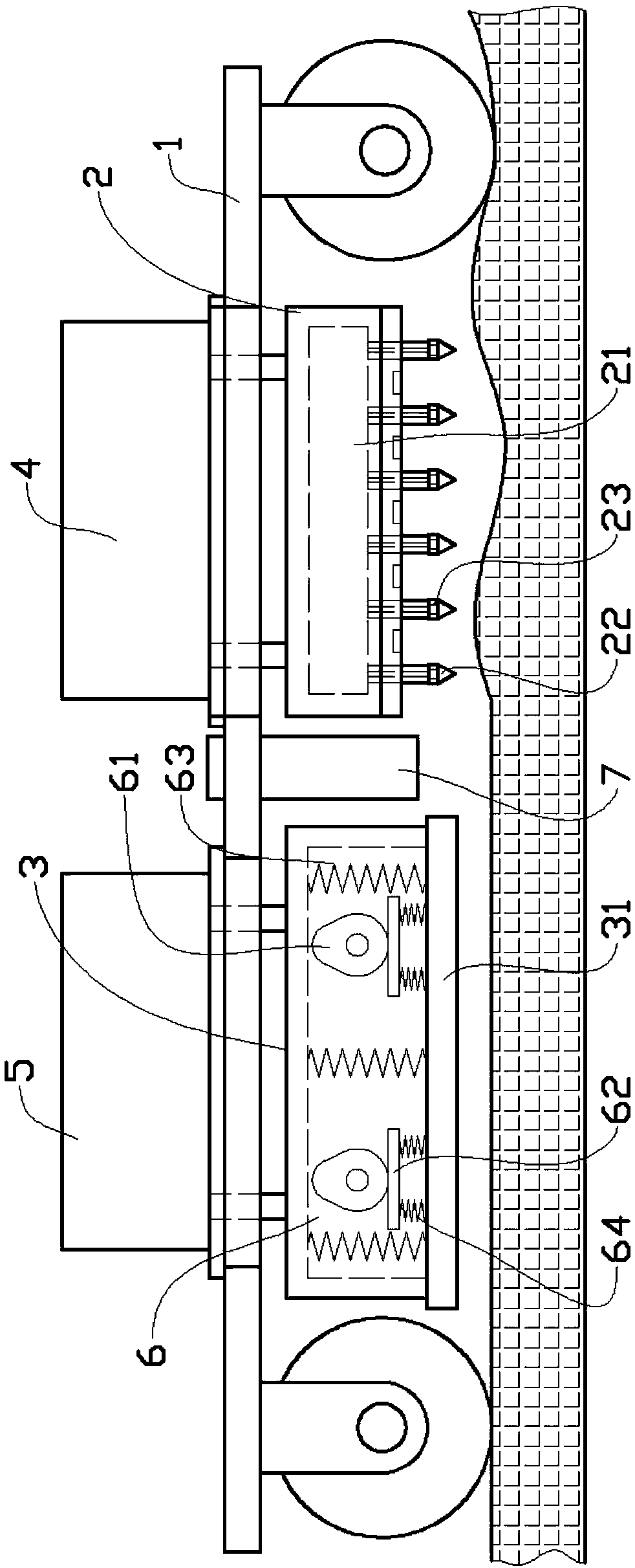

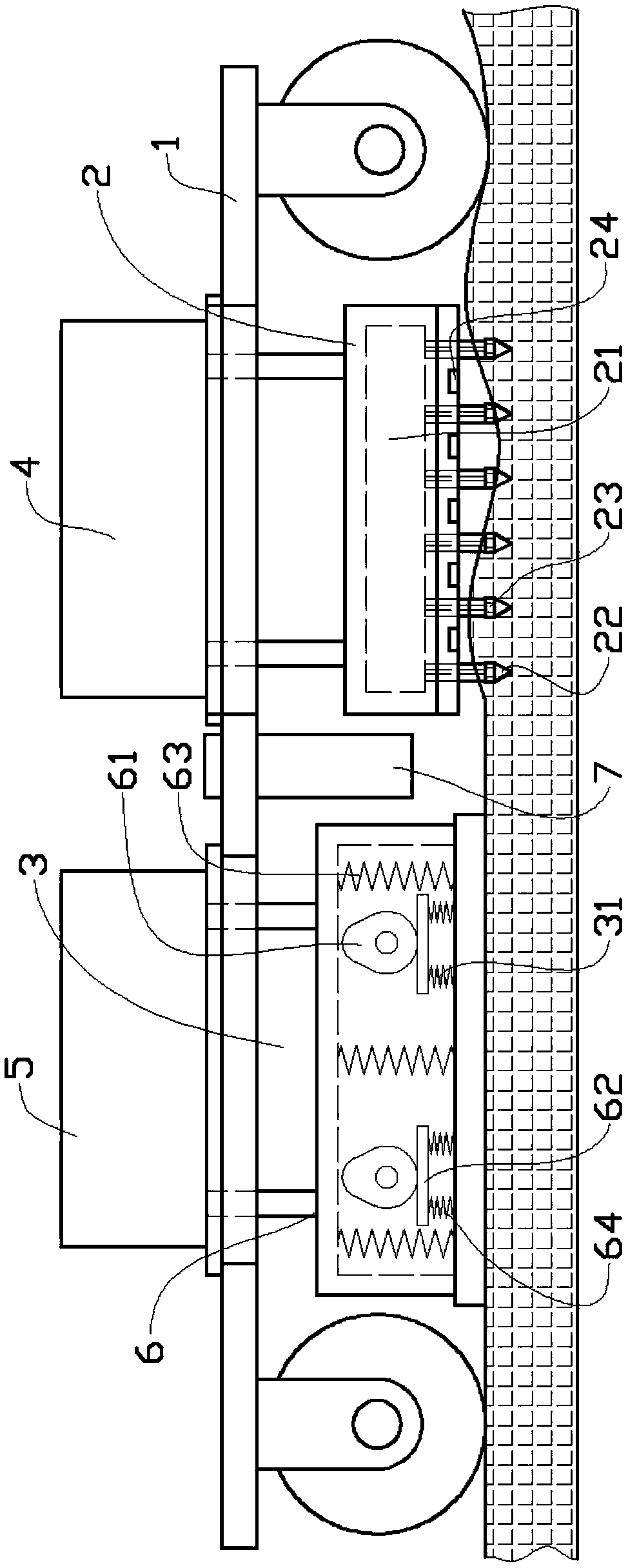

[0014] Such as figure 1 and figure 2 As shown in the embodiment, the asphalt pavement leveling device includes a vehicle frame 1, a hot-melt module 2 and a flattening module 3 assembled on the vehicle frame 1 side by side. The vehicle frame 1 can use a separate vehicle condition structure to be dragged by other vehicles, or it can be directly designed on the rear of the truck. The hot-melt module 2 can move up and down on the front of the vehicle frame 1 through the front transmission module 4, and the flattening module 3 can move up and down on the rear of the vehicle frame 1 through the rear transmission module 5; The hot-melt module 2 is equipped with a rotating module 21 inside, and the lower part of the rotating module 21 is equipped with a drill bit 22 protruding downward from the hot-melt module 2. The front part of the drill bit 22 adopts a traditional drilling structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com