Small nitrogen producing and filling machine

A small, control valve technology, applied in the direction of inorganic chemistry, mechanical equipment, nitrogen compounds, etc., can solve the problems of difficulty in adapting to the needs of modern warfare, difficulty in ensuring reliability, and time-consuming, so as to promote practical application, improve filling capacity and The effect of performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

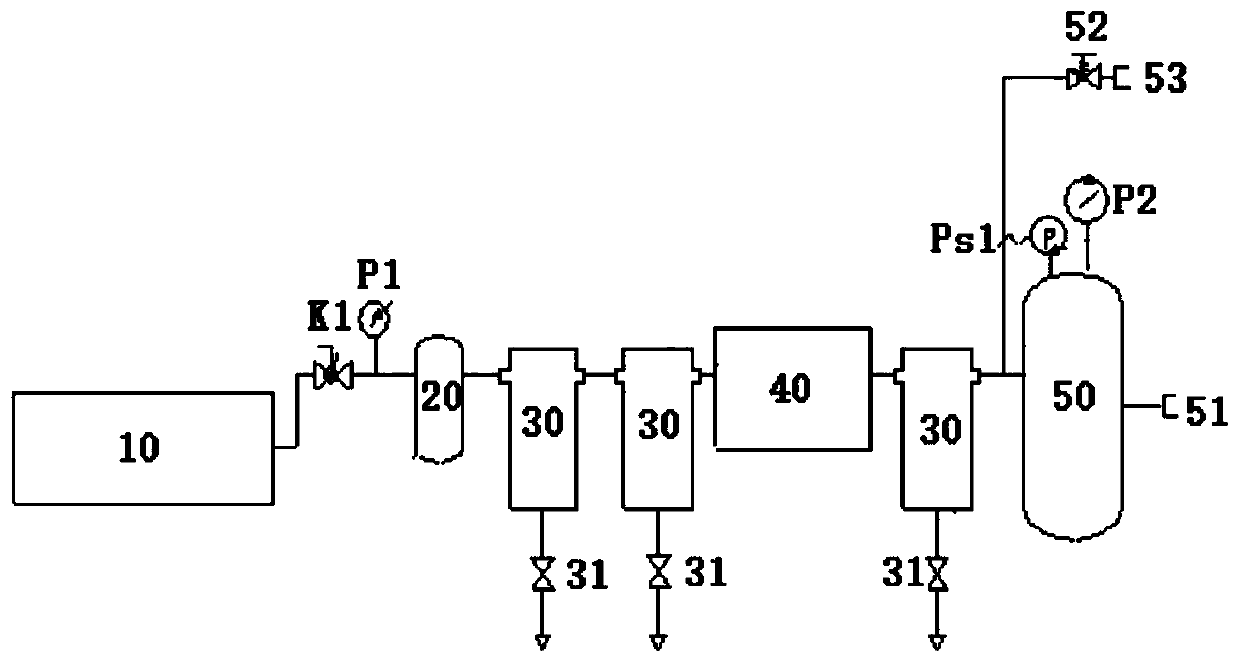

[0030] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

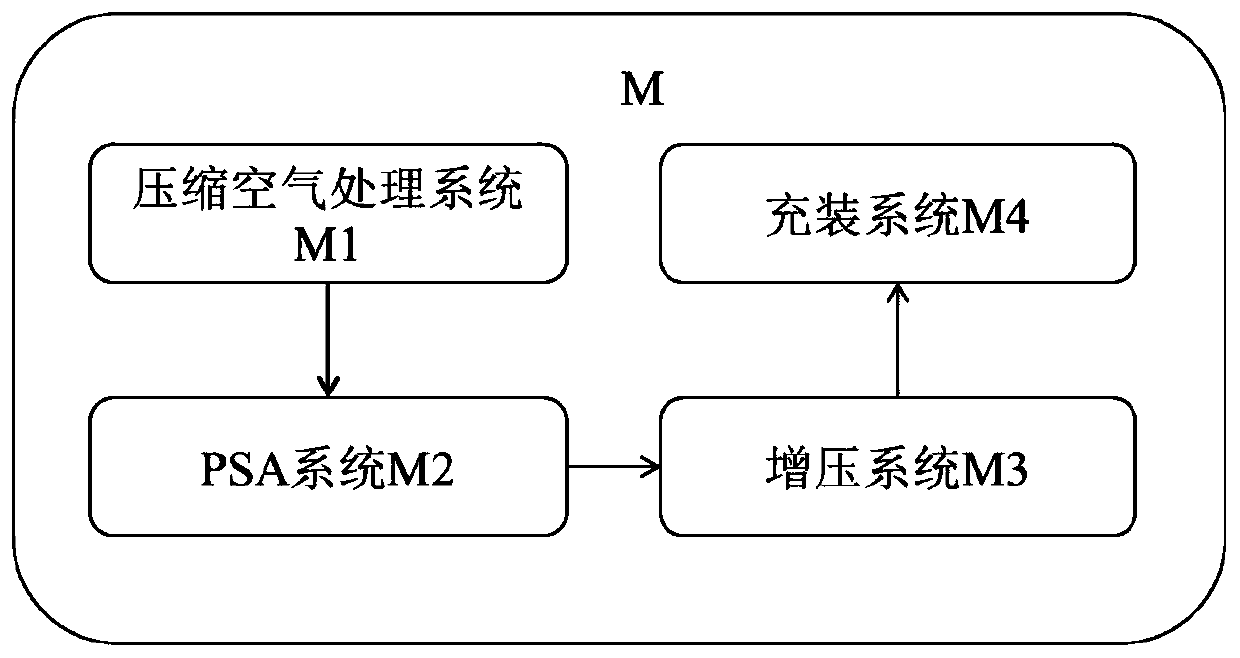

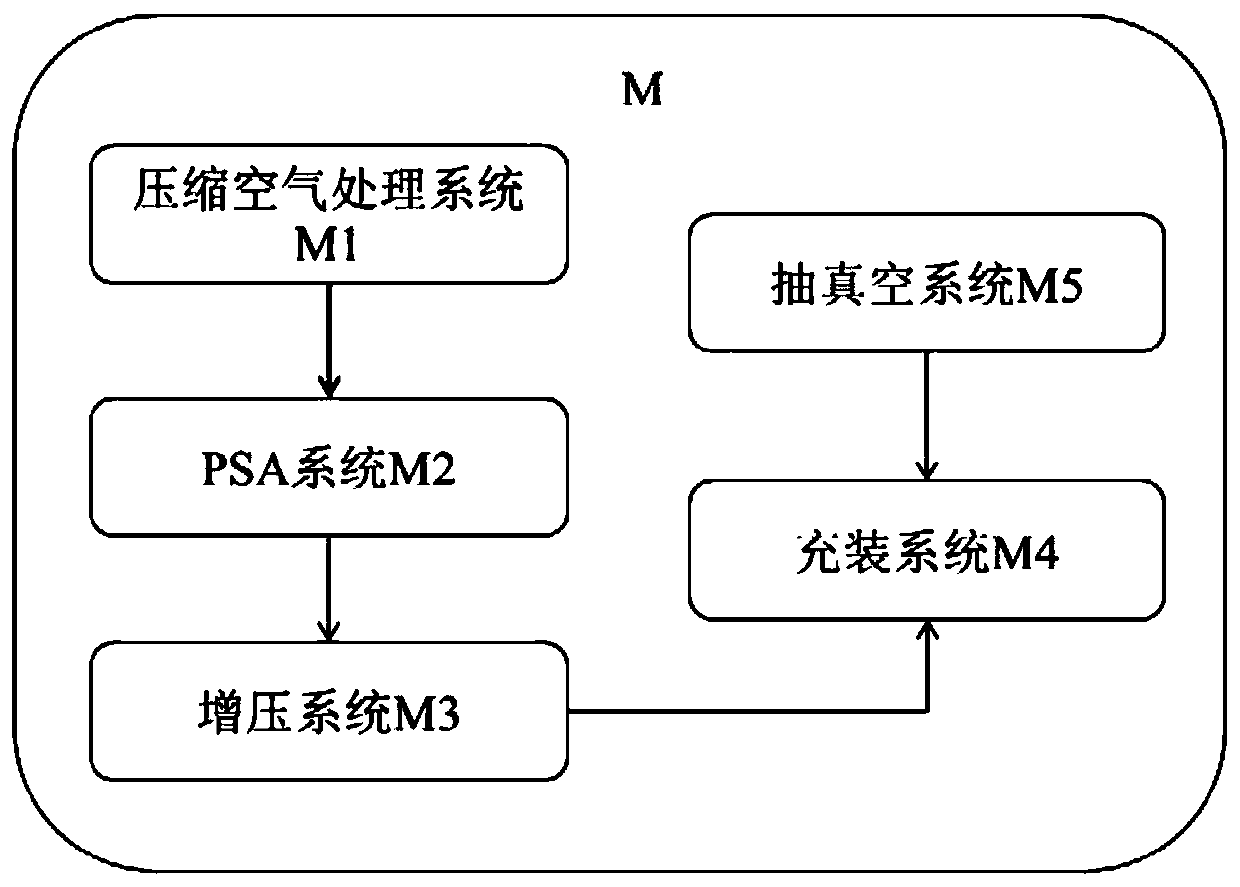

[0031] Such as figure 1 As shown, the small-scale nitrogen-generating filling machine M of this embodiment includes: a compressed air treatment system M1, which completes the drying and purification treatment of compressed air; a PSA system M2, which forms dry air after the compressed air passes through the compressed air treatment system M1 and enters the The PSA system M2; the supercharging system M3, the qualified nitrogen prepared by the PSA system M2 enters the supercharging system M3; and the filling system M4, the high-pressure nitrogen gas that is pressurized by the supercharging system M3 enters The filling system M4 performs filling.

[0032] Wherein, the compressed air processing system M1, the PSA system M2, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com