Small intelligent nitrogen producing and filling machine

A nitrogen generator and intelligent technology, applied in inorganic chemistry, mechanical equipment, nitrogen compounds, etc., can solve the problems of difficult to guarantee reliability, difficult to adapt to the needs of modern warfare, laborious, etc., to improve filling capacity and performance indicators, The effect of promoting practical use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The idea, specific structure and technical effects of the present application will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present application.

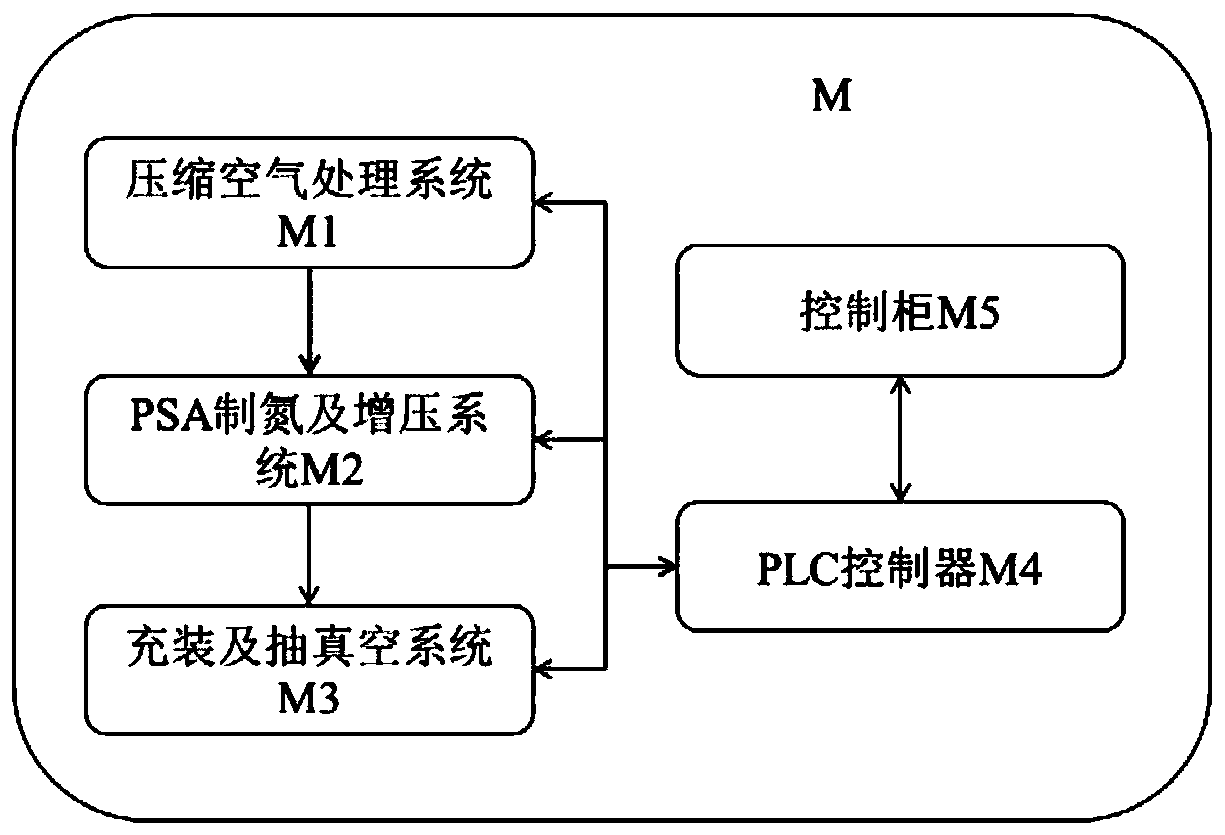

[0032] like figure 1As shown, the small intelligent nitrogen filling machine M of this embodiment includes: a PLC controller M4, which is electrically connected to the electric control cabinet M5; a compressed air processing system M1, which is electrically connected to the PLC controller M4, and the compressed air The air treatment system M1 is used to dry and purify compressed air and form dry air; the PSA nitrogen production and pressurization system M2 is electrically connected to the PLC controller M4, and the PSA nitrogen production and pressurization system M2 utilizes a dry After the air completes the nitrogen production, pressurization of nitrogen is carried out; and the filling and vacuuming system M3 is electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com