Carburization equipment and carburization method

A carburizing and equipment technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of oxidation and affecting the heating equipment of the carburizing chamber, so as to simplify the loading procedure and protect the heating equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

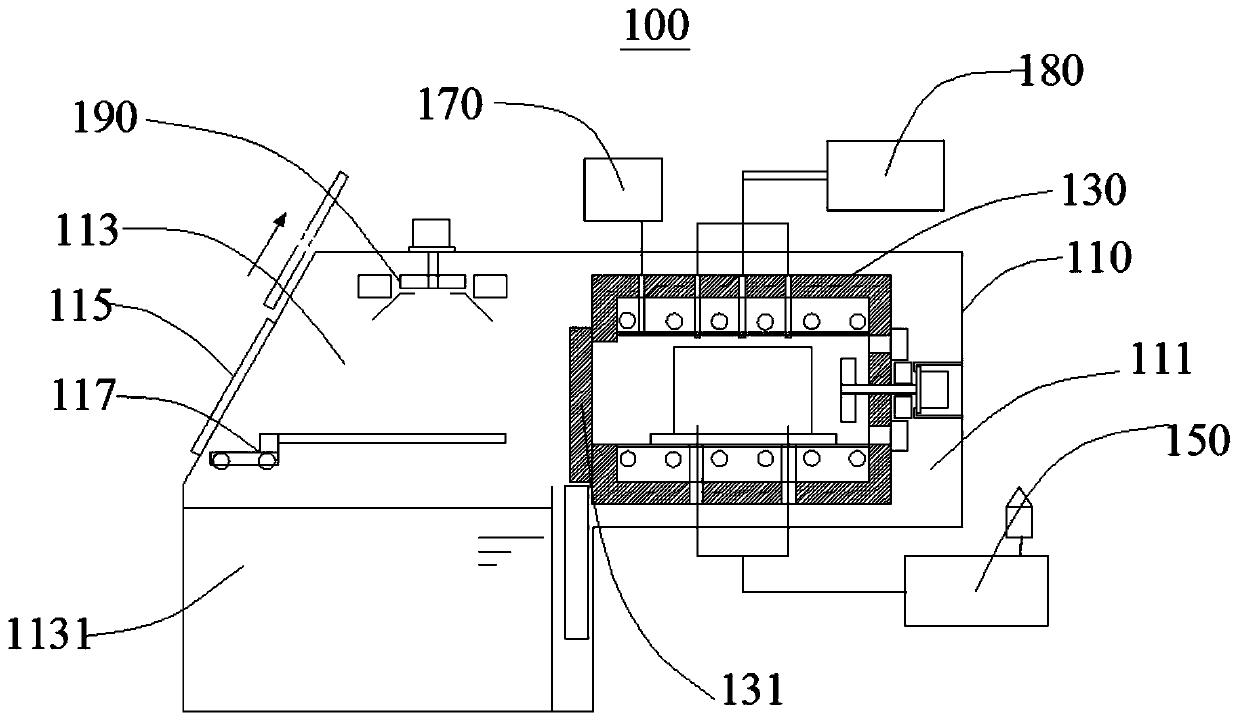

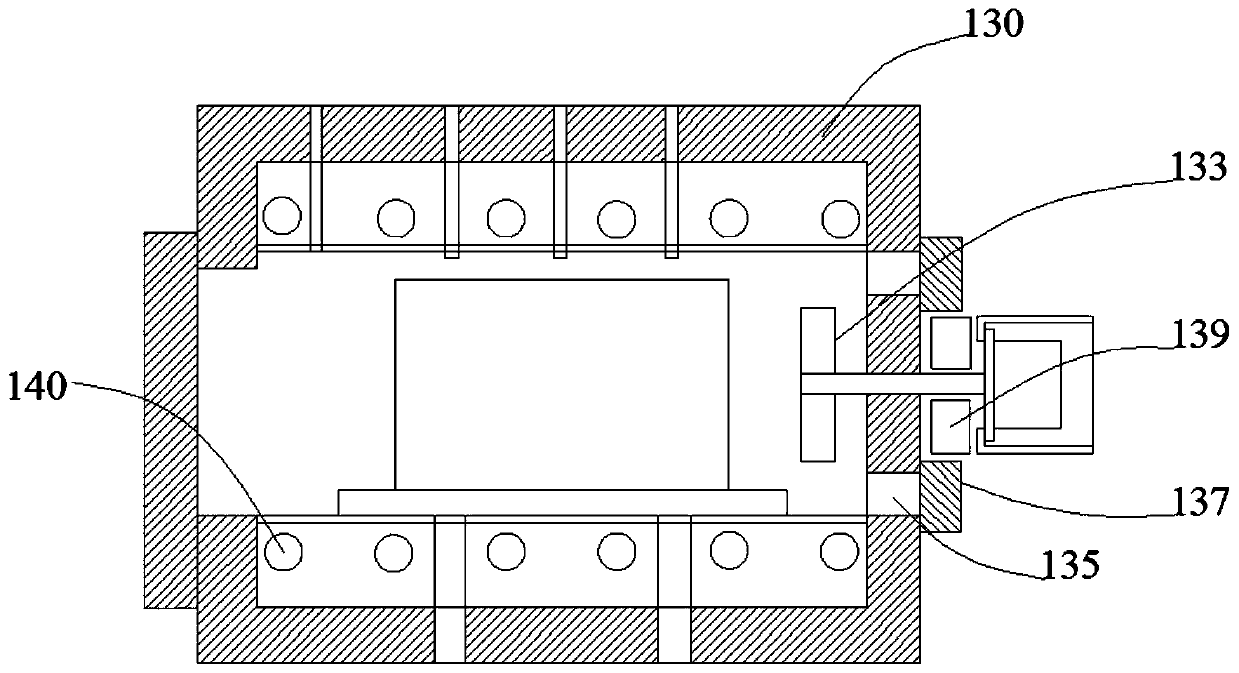

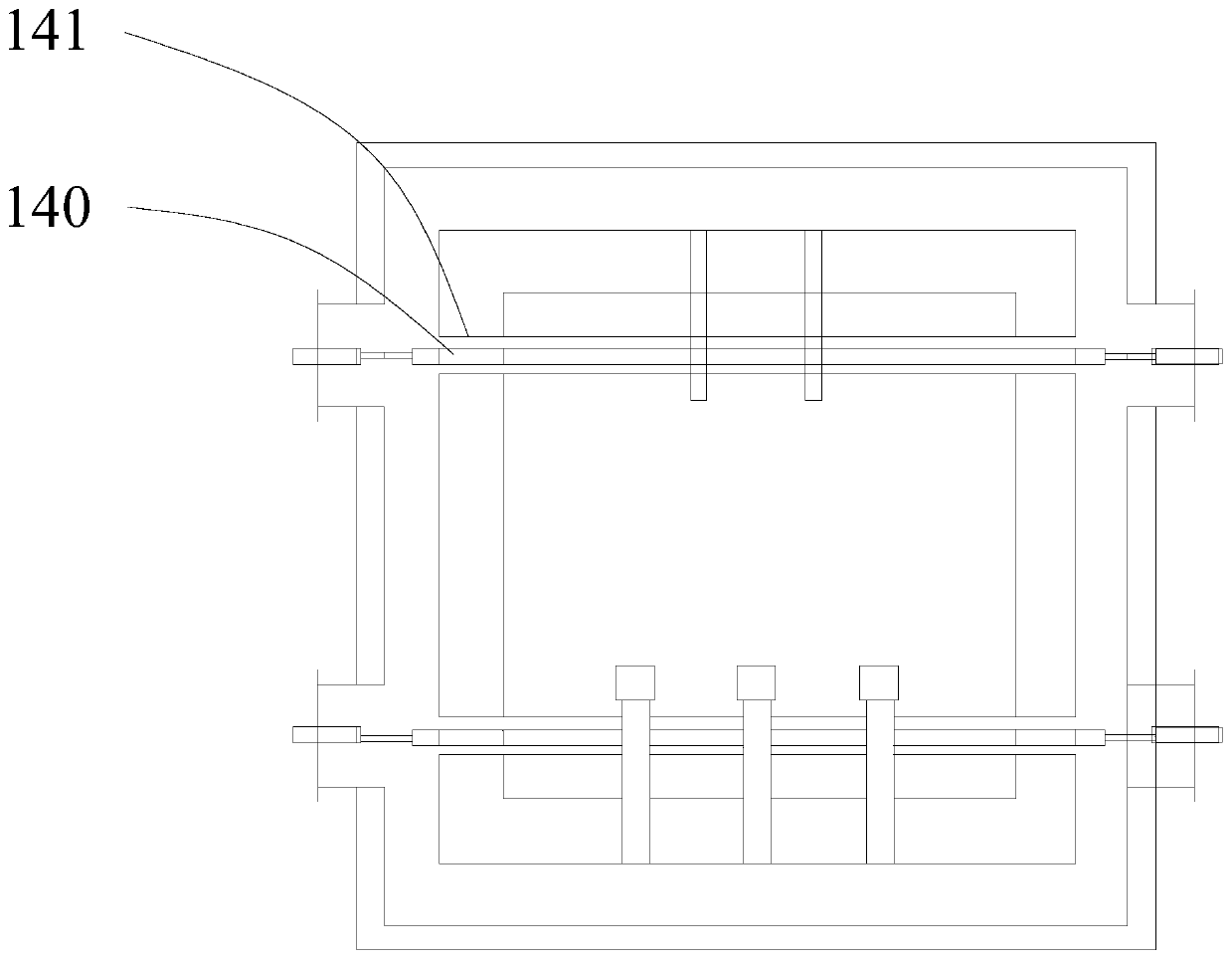

[0040] see figure 1, the present embodiment provides a carburizing equipment 100, including a housing housing 110, a heating chamber 130, a vacuum processing device 150, an exhaust gas inlet device 170 and a carburizing gas inlet device 180, the housing housing 110 There is a carburizing zone 111 and a cooling zone 113 which communicate with each other. The heating chamber 130 is arranged in the carburizing zone 111. A heat-sealed door 131 is opened at one end of the heating chamber 130 to isolate the inside of the heating chamber 130 from the cooling zone 113. The air inlet device 170 is connected to the heating chamber 130, and is used to feed exhaust gas into the heating chamber 130, and the carburizing gas inlet device 180 is connected to the heating chamber 130, and is used to feed carburizing gas into the heating chamber 130. , the bottom of the heating chamber 130 is provided with a flow hole communicating with the carburizing area 111 , and the vacuum treatment device ...

no. 2 example

[0067] see Figure 5 , this embodiment provides a carburizing method, which is suitable for the carburizing equipment 100 provided in the first embodiment.

[0068] The carburizing method provided by the present embodiment comprises the following steps:

[0069] S1: Load the workpiece into the cooling zone 113.

[0070] Specifically, open the feeding door 115 on the accommodating housing 110 , use the feeding device 117 to send the workpiece into the feeding port, and stay in the cooling zone 113 .

[0071] S2: Pass exhaust gas into the heating chamber 130 .

[0072] Specifically, nitrogen gas is fed into the heating chamber 130 through the exhaust gas inlet device 170, so that the heating chamber 130 is filled with nitrogen gas, and air entering the cooling zone 113 from the feeding port is prevented from entering the heating chamber 130 through the flow holes. During actual charging, because the inside of the heating chamber 130 is high temperature, the heat-sealed door 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com