Construction device and construction method of all-round rotary cutting mixed (arm) pile

A construction device and all-round technology, which is applied to the drilling driving device, sheet pile wall, earthwork drilling and other directions in the wellbore, can solve the problems of not being able to achieve high-quality cement-soil mixing piles, etc., and achieve simple and reliable structure and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

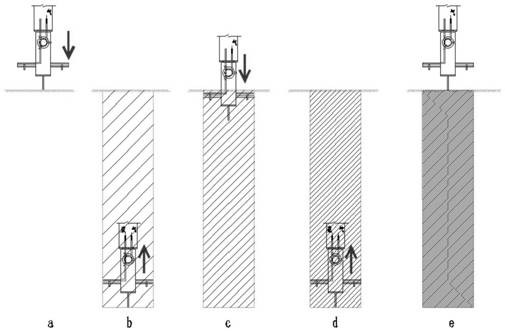

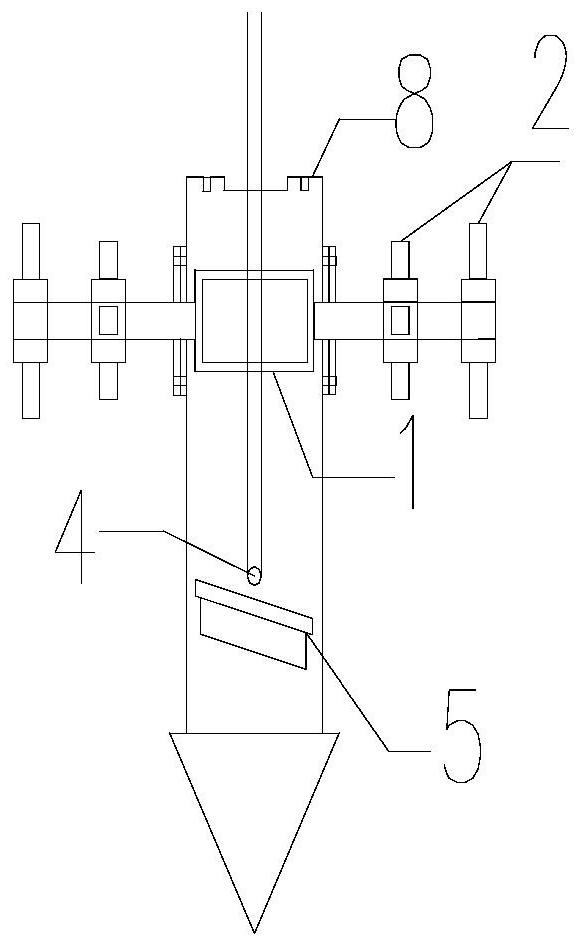

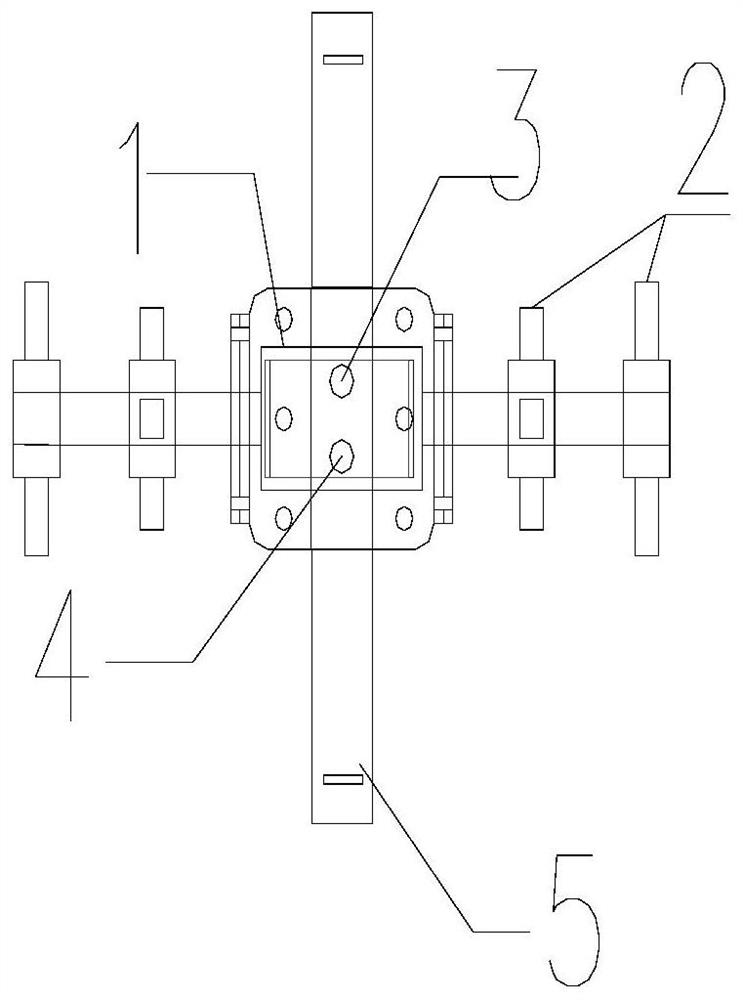

[0024] Below in conjunction with accompanying drawing, construction device and construction method are introduced in detail. A project uses cement-soil mixing piles for foundation treatment. The designed pile diameter is 600mm, and the construction is carried out using an all-round rotary cutting and mixing (ARM) pile construction device. The construction device includes a mixing drill bit, and the end of the mixing drill bit is a tapered drill tip , a certain distance from the top of the drill tip and two pairs of aerodynamic agitation blades are provided on both sides at a certain distance from the top of the agitation blade. Two pairs of pneumatic agitation blades extend from the drill bit. The hollow part of the drill bit is connected to the air motor; the top of the mixing bit is provided with a flange for connecting with the drill pipe driving device, and the hollow part of the mixing bit is provided with a grouting pipe and an air pipe, and the air pipe is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com