Novel energy-saving type gas stove

An energy-saving, gas-fired stove technology, applied in the field of gas stoves, can solve the problems of reduced heat of utensils, general energy-saving effect, low utilization rate of heat energy, etc., and achieves the effects of improving hardness, improving the bonding performance of blank-glaze, and providing utilization rate of heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

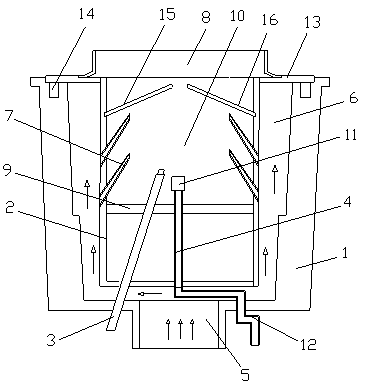

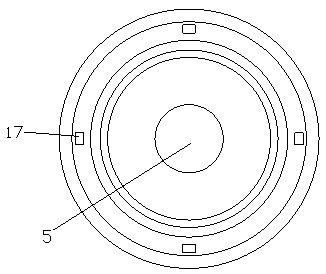

[0037] Such as Figure 1-2 As shown, a new type of energy-saving gas stove includes an outer shell 1, an insulated inner shell 2, an igniter 3, and a connecting pipe 4. The insulated inner shell 2 is located in the outer shell 1, and the outer shell 1 and the insulated inner shell 2 is fixedly connected, the outer shell 1 is provided with an air inlet 5, an air cavity 6 is formed between the outer shell 1 and the heat-insulating inner shell 2, and the air inlet 5 and the air cavity 6 are communicated with each other. 2 is provided with an exhaust pipe 7, the heat-insulating inner shell 2 and the exhaust pipe 7 are detachably connected, the heat-insulating inner shell 2 is provided with a fire ring 8, and the heat-insulating inner shell 2 is provided with The heat-insulating plate 9 forms a combustion chamber 10 between the fire-gathering ring 8, the heat-insulating inner shell 2 and the heat-insulating plate 9, and the combustion chamber 10 is in communication with the air cavi...

Embodiment 2

[0051] Such as Figure 1-2 As shown, a new type of energy-saving gas stove includes an outer shell 1, an insulated inner shell 2, an igniter 3, and a connecting pipe 4. The insulated inner shell 2 is located in the outer shell 1, and the outer shell 1 and the insulated inner shell 2 is fixedly connected, the outer shell 1 is provided with an air inlet 5, an air cavity 6 is formed between the outer shell 1 and the heat-insulating inner shell 2, and the air inlet 5 and the air cavity 6 are communicated with each other. 2 is provided with an exhaust pipe 7, the heat-insulating inner shell 2 and the exhaust pipe 7 are detachably connected, the heat-insulating inner shell 2 is provided with a fire ring 8, and the heat-insulating inner shell 2 is provided with The heat-insulating plate 9 forms a combustion chamber 10 between the fire-gathering ring 8, the heat-insulating inner shell 2 and the heat-insulating plate 9, and the combustion chamber 10 is in communication with the air cavi...

Embodiment 3

[0065] Such as Figure 1-2 As shown, a new type of energy-saving gas stove includes an outer shell 1, an insulated inner shell 2, an igniter 3, and a connecting pipe 4. The insulated inner shell 2 is located in the outer shell 1, and the outer shell 1 and the insulated inner shell 2 is fixedly connected, the outer shell 1 is provided with an air inlet 5, an air cavity 6 is formed between the outer shell 1 and the heat-insulating inner shell 2, and the air inlet 5 and the air cavity 6 are communicated with each other. 2 is provided with an exhaust pipe 7, the heat-insulating inner shell 2 and the exhaust pipe 7 are detachably connected, the heat-insulating inner shell 2 is provided with a fire ring 8, and the heat-insulating inner shell 2 is provided with The heat-insulating plate 9 forms a combustion chamber 10 between the fire-gathering ring 8, the heat-insulating inner shell 2 and the heat-insulating plate 9, and the combustion chamber 10 is in communication with the air cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com