Manufacturing method of vertical horse Jun porcelain craft

A production method and handicraft technology, which is applied in the production field of Lima Jun porcelain handicrafts, can solve the problems of easy cracking, low yield rate, and difficulty in achieving artistic effects, and achieve the effect of strong tendons, high yield rate, and high difficulty in firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

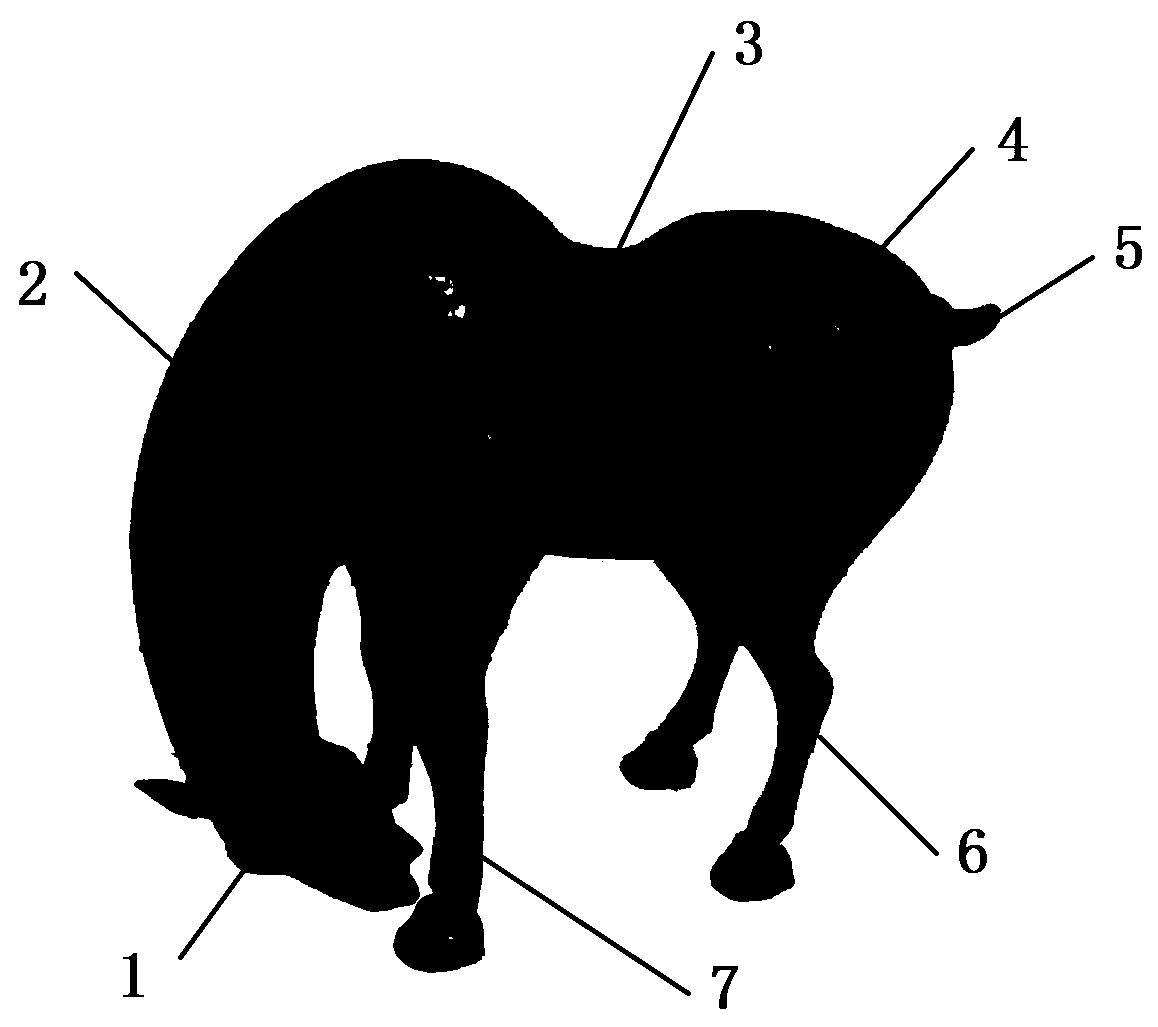

[0021] Such as figure 1 Shown, a kind of manufacture method of Lima Jun porcelain handicraft, comprises the following steps:

[0022] Step 1. Carve the model; divide the whole handicraft into multiple parts to carve separately, including horse head 1, horse neck 2, horse body 3, horse buttocks 4, horse front legs 7, horse hind legs 6 and horse tail 5, horse neck 2 directions Bend down, the horse head 1 is downward, the mouth of the horse head 1 is on the side of the left front leg, and it is not glued to the left front leg;

[0023] Step 2, making a mould; making plaster moulds, respectively, from the parts carved in step 1;

[0024] Step 3, selecting pottery clay; the pottery clay includes the following components: 50 parts of kaolin, 5 parts of alkaline earth, 5 parts of quartz stone, 10 parts of sandstone, 10 parts of lead powder, 8 parts of mullite, and 1 part of iron ore;

[0025] Step 4, pulping; the pottery clay in step 3 is first roughly crushed into sand or powder, ...

Embodiment 2

[0033] Such as figure 1 Shown, a kind of manufacture method of Lima Jun porcelain handicraft, comprises the following steps:

[0034] Step 1, engraving the model; divide the whole handicraft into multiple parts to carve respectively, including horse head, horse neck, horse body, horse buttocks, horse front legs, horse hind legs and horse tail, the horse neck is bent downward, and the horse head is Below, the mouth of the horse's head is on the side of the left foreleg;

[0035] Step 2, making a mould; making plaster moulds, respectively, from the parts carved in step 1;

[0036] Step 3, select pottery clay; the pottery clay includes the following components: 65 parts of kaolin, 10 parts of alkaline earth, 5 parts of quartz stone, 8 parts of sandstone, 10 parts of lead powder, 8 parts of mullite, and 2 parts of iron ore;

[0037] Step 4, pulping; the pottery clay in step 3 is first roughly crushed into sand or powder, and then ground to a fineness of 230-250 mesh, mixed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com