Making method of bamboo joint flower vase jun porcelain artware

A production method and handicraft technology, applied in decorative art, clay products, special decorative structures, etc., can solve the problems that affect the value and yield of Jun porcelain, and achieve good glaze bonding performance, beautiful appearance, and uniform glaze color distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

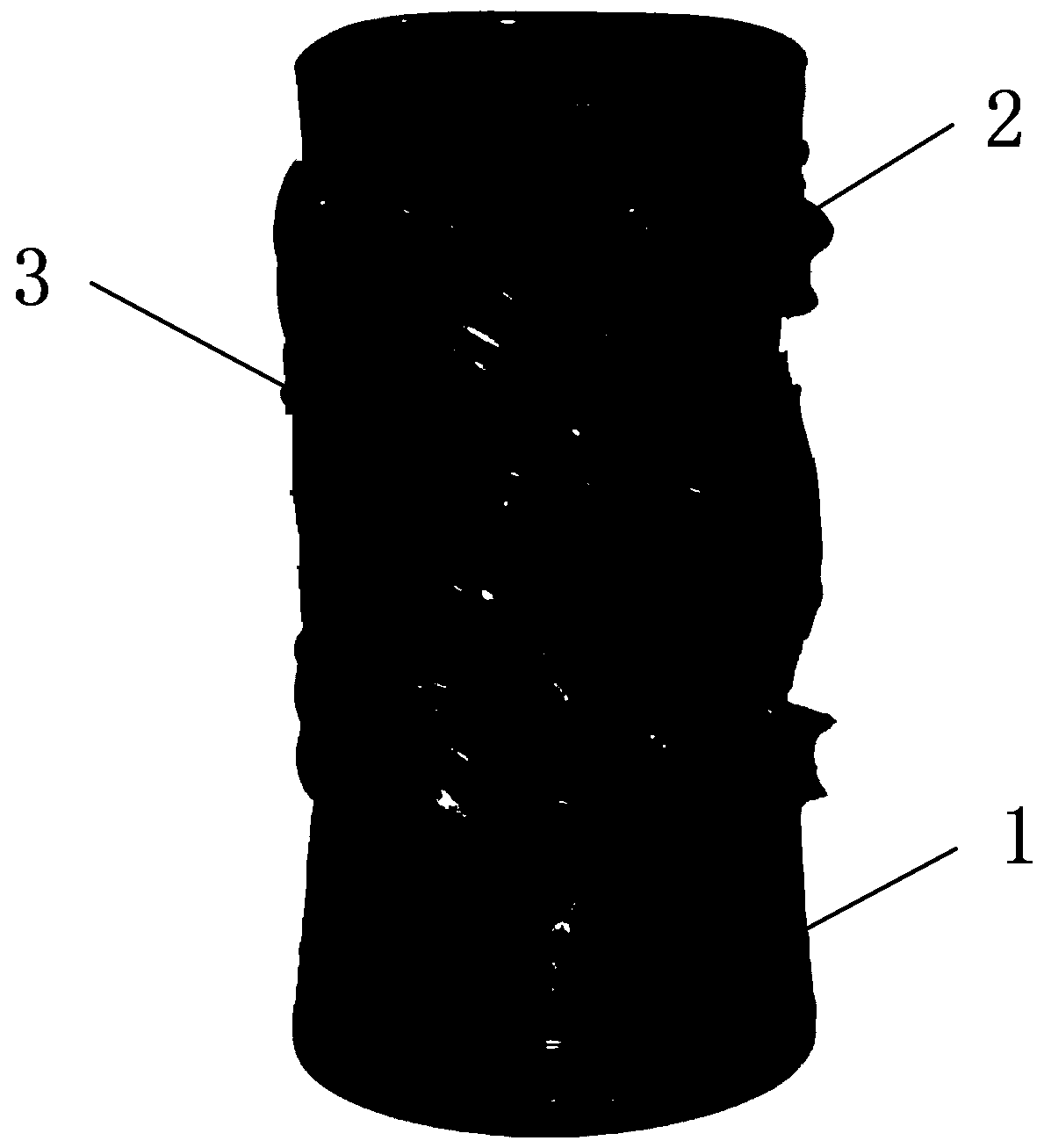

[0021] Such as figure 1 Shown, a kind of manufacture method of bamboo vase Jun porcelain handicraft, comprises the following steps:

[0022] Step 1. Select pottery clay; the pottery clay includes the following components: 50 parts of kaolin, 5 parts of alkaline earth, 3 parts of quartz stone, 8 parts of sandstone, 8 parts of lead powder, 8 parts of mullite, and 1 part of iron ore;

[0023] Step 2, practice mud; first coarsely crush the clay into sand or powder, then grind it, add water and mix it into a mud ball;

[0024] Step 3, drawing the blank; the mud ball is drawn out of the blank of the bottle body 1, and the mouth of the cup is square;

[0025] Step 4, mold making; carve the models of the ball 3 and the bamboo leaf 2 respectively, and make plaster molds with the carved models;

[0026] Step 5, grouting molding; the pottery clay in step 1 is first roughly crushed into sand or powder, and then ground to a fineness of 230 mesh, mixed with water and ball milled to make a...

Embodiment 2

[0033] A method for making a Jun porcelain handicraft with a bamboo vase, comprising the following steps:

[0034] Step 1. Select pottery clay; the pottery clay includes the following components: 65 parts of kaolin, 10 parts of alkaline earth, 5 parts of quartz stone, 12 parts of sandstone, 10 parts of lead powder, 10 parts of mullite, and 2 parts of iron ore;

[0035] Step 2, practice mud; first coarsely crush the clay into sand or powder, then grind it, add water and mix it into a mud ball;

[0036] Step 3, drawing the blank; the mud ball is drawn out of the blank of the bottle body, and the mouth of the cup is square;

[0037] Step 4, mold making; carve the models of the ball 3 and the bamboo leaf 2 respectively, and make plaster molds with the carved models;

[0038] Step 5, grouting molding; the pottery clay in step 1 is first roughly crushed into sand or powder, and then ground to a fineness of 250 mesh, mixed with water and ball milled to make a slurry; then the slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com